BBQ Charcoal Production Line Coal Briquettes Making Machines

BBQ Briquettes Processing Plant | Charcoal Ball Making Machines

BBQ Charcoal Production Line Coal Briquettes Making Machines

BBQ Briquettes Processing Plant | Charcoal Ball Making Machines

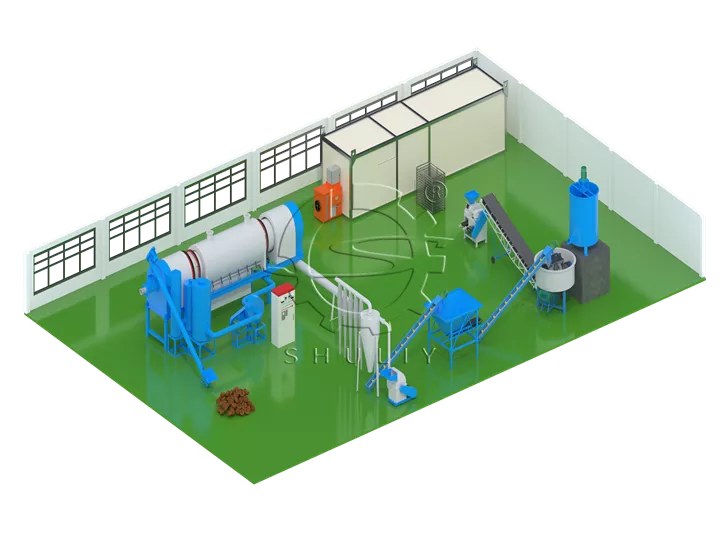

The BBQ charcoal production line consists of several processes, from raw material handling to the packaging of the finished product, realizing the whole process of transforming wood into high-quality barbecue charcoal.

Barbecue charcoal ball processing plants can produce coal ball briquettes of various specifications sizes and shapes. Production capacity ranges from 300 kg/h to 2000 kg/h with high flexibility and can be customized to meet different production needs. These production line machines have been sold to Saudi Arabia, Iran, Egypt, Libya, South Africa, and so on.

Raw materials for BBQ charcoal production line

Barbecue charcoal is made from a variety of raw materials, usually including the following types: rice hulls, coconut shells, wood chips, bamboo, straw, fruit shells, and so on.

Finished products from charcoal ball making line

The finished products of the BBQ charcoal production line are characterized by high calorific value, low smoke, and less smoke, long burning time, uniform charcoal particles, no odor, environmentally friendly and sustainable, and easy to store and transport.

These charcoals can be used in home combustion, boilers, barbecues, fireplace heating, power plants, and so on.

In addition, due to its unique microporous structure and super adsorption capacity. It is widely used in many fields such as food, pharmaceutical, chemical, metallurgy, national defense, agriculture, and environmental protection.

Charcoal briquette production line workflow

Production process: Carbonizing → Crushing → Mixing and Pressing → Forming → Drying → Packaging

Production line equipment matching: Continuous carbonization furnace → Hammer mill → Wheel mill mixer → Charcoal ball briquette machine → Mesh belt dryer → Package machine

Main process of making Barbeque coal balls

The machines required for the machining process and the corresponding parameter information are listed in the following order.

Continuous carbonization furnace

The moisture and volatile organic compounds in the wood will be decomposed and removed, leaving behind the charcoal with high calorific value and high carbon content.

- Model: SL-800

- Dimension: 9*2.6*2.9m

- Power: 22kw

- Capacity: 300-400kg/h

- Weight: 9ton

- Machine shell thickness(steel): 11mm

Charcoal grinder machine

Further crush and grind the charcoal after carbonization to obtain charcoal particles suitable for barbecue use.

Specifically, the coal powder is made to have a certain granularity and uniformity to improve the burning efficiency and quality of the charcoal.

- Model: SL-W-1300

- Power: 5.5kw

- Capacity: 300-500kg/h

- Inner diameter:1300mm

Glue mixer

The purpose of a glue mixer is to mix charcoal particles with an adhesive or binder. Then bond the charcoal particles together to form a strong charcoal block.

This helps to improve the stability, durability, and molding of the charcoal, making the charcoal product easier to store, transport, and use.

- Model: SL-M800

- Input capacity: 0.6m³

- Power: 3kw

- Inner diameter: 800mm

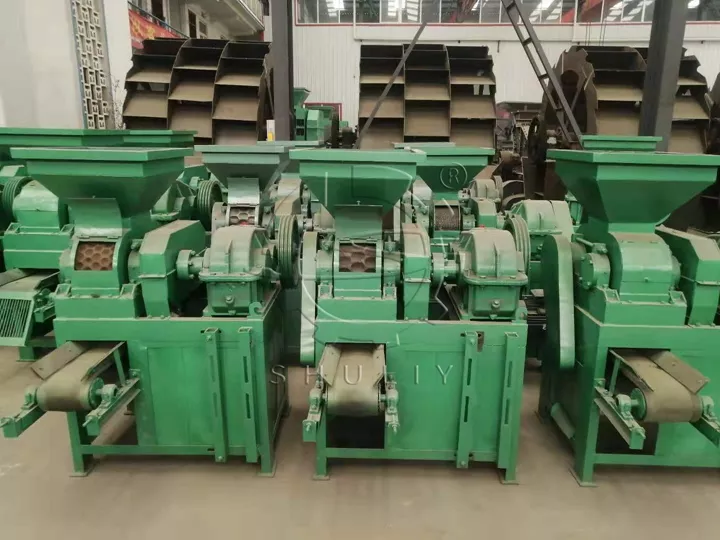

Charcoal ball press machine

This machine presses the mixing and blending of processed charcoal particles together with the binder into charcoal balls or lumps of a certain shape and size.

This helps to further improve the stability, and durability of the charcoal, making the charcoal product easier to store, transport, and use. Its working principle can be viewed by clicking on the Charcoal ball press machine for the BBQ industry.

- Power: 5.5kw

- Capacity: 1-2t/h

- Pressure: 50tons per time

- Weight: 720kg

Mesh belt drying machine

The role of the dryer in the BBQ charcoal production line is to dry the molded charcoal. This can improve the burning efficiency, quality, and storage stability of the charcoal.

BBQ charcoal packing machine

Quantitative packaging machines accurately quantify and package charcoal products that have been processed, molded, and dried to a predetermined weight.

This helps to ensure the consistent quality of charcoal products in each packaging unit for easy storage, transportation, and distribution.

- Packing weight: 20-50kg per bag

- Packing speed: 300-400 bags per hour

- Power: 1.7kw

- Dimension: 3000*1150*2550mm

BBQ charcoal processing plant advantages

The BBQ charcoal production line has many advantages that make it ideal for efficient and high-quality charcoal product production.

- High-quality products: the barbecue charcoal production line produces charcoal products by ensuring the uniformity, stability, and combustion efficiency of charcoal particles through fine processing procedures.

- Efficient energy utilization: the charcoal furnace, dryer, and other equipment adopt the technology of efficient energy utilization, which reduces energy consumption and lowers production costs.

- Consistency and standardization: automated production ensures consistency and standardization of products, improving the appearance and quality consistency of products.

- Convenient packaging: quantitative packaging machines can accurately package charcoal products into units of specified weight or capacity for easy storage, transportation, and distribution.

We can provide free production line design

When planning to set up a BBQ charcoal production line, please provide us with detailed information, including:

- Type, size, and moisture content of the raw material

- Plant size

- Transformer capacity

- Type and size of the finished product

- Output demand

The more detailed, the better, as this will allow us to customize your equipment to your specific needs. We will also provide you with free 3D site planning diagrams.

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine, also known as a briquette extruder…

Shisha Charcoal Making Machine For Hookah Briquette Tablet

The stainless steel hydraulic shisha charcoal making machine is used…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

The hydraulic shisha charcoal briquette machine uses the power of…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Rotary shisha charcoal making machine is a double-press type automatic…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is used to press powdered raw…

Honeycomb Coal Machine For Briquette Forming Production Line

The Honeycomb coal machine is to regard the well-processed coal…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Charcoal Grinder Machine For Briquette Molding Plant

The charcoal grinder machine, also known as a mixing mill,…

Hot Product

Briquette Charcoal Dryer For Honeycomb Shisha Coal Production

Briquette charcoal dryer refers to the evaporation of…

Wood Crusher Machine For Making Sawdust

The wood crusher machine plays a crucial role…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…

Feed Pellet Mill Machine For Animal Livestock

Feed pellet mill is used for making animal…

Honeycomb Coal Machine For Briquette Forming Production Line

Honeycomb coal machine regards well-processed coal dust as…

Wood Shaving Machine For Animal Bedding

Wood shaving machine planes wood into thin slices…

Automatic Saw Mill Machine For Wood Recycling Plant

An automatic saw mill machine is a mechanical…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The charcoal making furnace is used for charring…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

Hydraulic shisha charcoal briquette machine is also a…