Feed Pellet Mill Machine For Animal Livestock

Feed pellet machine | Poultry feed making machine

Feed Pellet Mill Machine For Animal Livestock

Feed pellet machine | Poultry feed making machine

Features at a Glance

The feed pellet mill machine is a kind of equipment used for processing animal feed, which granulates raw materials into certain sizes and shapes of pellets to meet the feeding needs of different animals.

With a simple structure and easy operation, the machine is widely used in the breeding industry and feed processing plants, which can effectively increase the utilization rate of feed, improve the growth and health of animals, and provide important technical support for the farming industry.

The feed pellet machine is widely used by people who raise animals or engage in the business of feed pellet production lines. They can make pellet feed for chickens, geese, pigeons, rabbits, cows, sheep, oxen, pigs, rabbits, and so on. They make pellet feed because it is a balanced combination of different kinds of nutrients for the better growth of livestock and other animals.

Raw materials of feed pellet mill

Feed Raw Materials: These raw materials can include a variety of grains (such as corn, wheat, soybeans, etc.), soybean meal, fish meal, meat and bone meal, vegetables, fruits, and so on. Larger-sized raw materials can be operated through the crushing machine first. Different types of animals require different feed ingredients, so the formulation of ingredients will vary according to the feeding needs of the animals.

Auxiliary ingredients: To improve the nutritional value and taste of the feed, some auxiliary ingredients can be added to the feed, such as vitamins, minerals, amino acids, and so on. These ingredients can help the animals to better absorb the nutrients and improve their growth rate and health condition.

Binding agent: Sometimes it is necessary to add some binding agent to help the raw materials in the pellet machine to better combine and compression, to produce uniform and stable particles. Common binding agents include starch, wood flour, etc.

Applications of poultry feed making machine

The feed pellet mill has a wide range of applications in the field of farming and feed processing, and its main applications include the following aspects:

- Livestock and Poultry Farming: Flat die feed pellet mills are widely used to produce feed pellets for livestock and poultry. Through granular processing, the feed can be better digested and absorbed, improving the growth rate, meat quality, and feeding efficiency of animals.

- Feed Processing Mills: Feed pellet mills are indispensable equipment in feed processing mills. Processing plants can use pellet mills to mix, granulate, and dry various ingredients to produce customized feeds that meet the feeding needs of different animals.

- Rural Family Farming: In some rural areas, flat die feed pellet mills are also used for small-scale family farming. This helps to improve farming efficiency, reduce waste, and enable better fulfillment of the food needs of the local population.

Overall, feed pellet mills play an important role in modern farming. By processing raw materials into pellet feed, they improve the digestibility and nutritional value of the feed and also promote the sustainable development of the farming industry.

Why choose Shuliy feed pellet machine?

Using a feed pellet mill has many advantages in the field of feed processing and farming, some of the main advantages are listed below:

- Pelletization improves digestibility: A flat die feed pellet mill can pelletize the raw materials to make the feed particles smaller and more uniform, which increases the surface area of the feed, helps the action of digestive enzymes, improves the digestibility of the feed, and makes it easier for the animals to absorb the nutrients.

- Improving feed quality: Granularization can help mix ingredients so that the different components are more evenly distributed in the pellets, thus improving the consistency and quality of the feed. This helps ensure that animals receive balanced nutrition for growth and health.

- Customized Feed Formulation: Flat die feed pellet mills offer the flexibility to adjust the pellet size and formulation according to the feeding needs of different animals. This allows feeders to customize the right feed for different growth stages and animal species.

- Adjustment of pellet size: By adding the baffle cutting device at the discharge of the machine, it can be adjusted according to the needs of different animals, to meet the feeding requirements of different stages and kinds of animals.

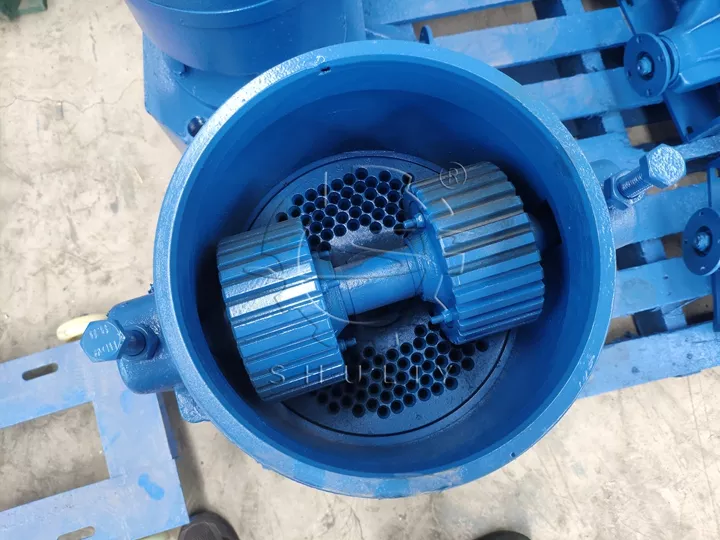

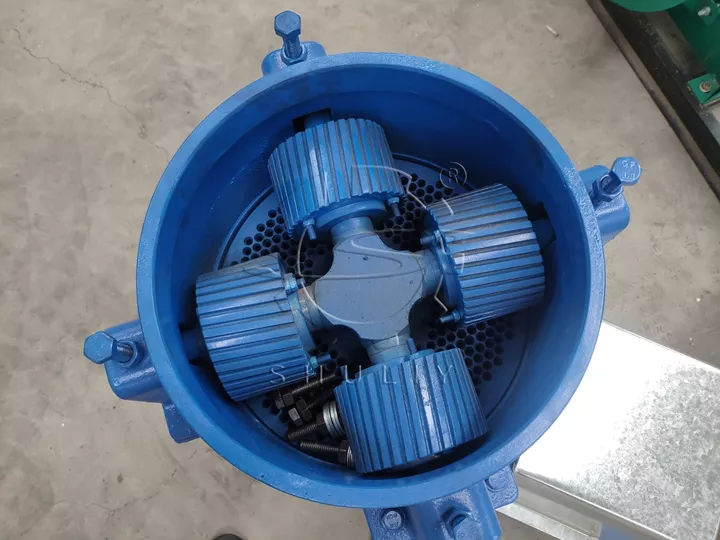

- Various models available: Different models are equipped with different numbers of grinding wheels, such as two three, or four, to grind the material onto the mold.

In addition, by changing the size of the holes in the mold, the diameter size of the outgoing finished product can thus be adjusted.

In summary, the advantages of feed pellet mills in farming and feed processing include improved feed quality, reduced waste, customized formulations, improved efficiency, etc., which provide important support for the development of the farming industry and the health of animals.

How to achieve poultry feed-making process?

The working principle of the feed pellet mill is to put raw materials into the machine from the inlet, after pressing and extruding action, the raw materials are pressed into granule shapes in the mold and cut into the required length by the cutting device.

Feeding

First, the feed ingredients are fed into the feed inlet of the flat die feed pellet mill, usually using a screw conveyor or other conveying device. The feed opening directs the feed material into the compression chamber of the pellet mill.

Pressing

Inside the pressing chamber, the raw material is subjected to a certain amount of squeezing force and pressure and is extruded and pressed through the press mold inside the machine. This gradually compresses the raw material into particles of a certain shape and size.

Cutting

After the pellets have passed through the die, they enter the cutting device. The cutting device usually consists of rotating blades or knife rollers that cut the continuous pellets to the desired length. This creates uniform feed pellets.

Cooling and drying

The cut pellets may still carry a certain degree of temperature and moisture. Therefore, a cooling and drying step is usually required to ensure the stability and storage properties of the pellets. This can be accomplished with equipment such as fans, coolers, and dryers.

Screening and grading

In some cases, pellets may need to be screened and graded to remove rejects or to sort the pellets by size. This helps to ensure the quality and consistency of the final product.

Feed pellet mill technical data

Our factory can process a variety of models of this machine, of which, according to sales data, there are the following two hot models of feed pellet mill.

| Model | Power | Capacity | Package weight | Packing size |

|---|---|---|---|---|

| SL-125 | 4kw | 80kg/h | 44+31 kg | 850*350*520mm |

| SL-210 | 7.5kw | 300kg/h | 100+65 kg | 990*430*770mm |

Successful cases of Shuliy feed pellet machine

Our machines have been selling well because of their good quality and great advantages in terms of price. Recently, we have successfully sent 25 sets of feed pellet mill machines to Saudi Arabia.

In conclusion, the feed pellet mill is an important tool for the modern farming industry, which provides farmers with high-quality feed production solutions, promotes the sustainable development of the farming industry, and also provides strong support for the growth and health of animals.

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

The rotary drum dryer machine is commonly used to evaporate…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives and a…

Automatic Saw Mill Machine For Wood Recycling Plant

The saw mill machine uses either a circular or band…

Wood Debarker Machine Timber Log Peeling Equipment

The wood debarker, equipped with high-strength alloy blades and advanced…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using the high-speed…

Wood Shaving Machine For Animal Bedding

The wood shaving machine is designed to transform wood of…

Wood Chipper Machine For Sawdust-making Plant

The wood chipper machine is designed to break down wood,…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down large pieces…

Automatic Wood Pallet Press Machine For Sale

The wood pallet press machine is our featured product, mainly…

Hot Product

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

Hydraulic shisha charcoal briquette machine is also a…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is efficient and convenient…

Horizontal Carbonization Furnace For Lump Charcoal Processing

Lump charcoal making machine is a kind of…

Multifunctional Shisha Hookah Charcoal Packing Machine For Sale

Hookah charcoal packing machine is a special equipment…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Automatic Saw Mill Machine For Wood Recycling Plant

The saw mill machine cuts larger logs into…

Briquette Charcoal Dryer For Honeycomb Shisha Coal Production

Briquette charcoal dryer refers to the evaporation of…