Línea de producción de carbón para barbacoas Máquinas para fabricar briquetas de carbón

Planta de procesamiento de briquetas para barbacoa | Máquinas para fabricar bolas de carbón

Línea de producción de carbón para barbacoas Máquinas para fabricar briquetas de carbón

Planta de procesamiento de briquetas para barbacoa | Máquinas para fabricar bolas de carbón

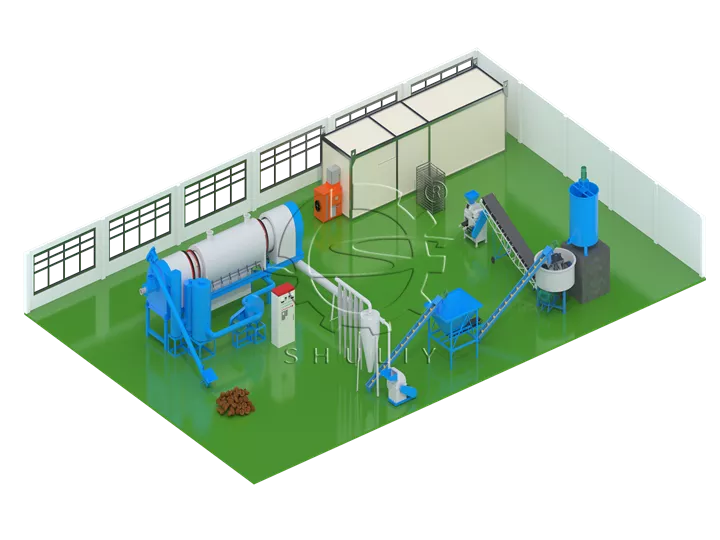

La línea de producción de carbón para barbacoa consta de varios procesos, desde el manejo de la materia prima hasta el envasado del producto terminado, realizando todo el proceso de transformación de la madera en carbón para barbacoa de alta calidad.

Las plantas de procesamiento de bolas de carbón para barbacoa pueden producir briquetas de bolas de carbón de diversas especificaciones, tamaños y formas. La capacidad de producción varía de 300 kg/h a 2000 kg/h con alta flexibilidad y se puede personalizar para satisfacer diferentes necesidades de producción. Estas máquinas de línea de producción se han vendido a Arabia Saudita, Irán, Egipto, Libia, Sudáfrica, etc.

Materias primas para la línea de producción de carbón para barbacoa.

El carbón para barbacoa se elabora a partir de una variedad de materias primas, que generalmente incluyen los siguientes tipos: cáscaras de arroz, cáscaras de coco, astillas de madera, bambú, paja, cáscaras de frutas, etc.

Productos terminados de la línea de fabricación de bolas de carbón.

Los productos terminados de la línea de producción de carbón para barbacoa se caracterizan por su alto poder calorífico, bajo nivel de humo y menos humo, largo tiempo de combustión, partículas de carbón uniformes, sin olor, respetuosos con el medio ambiente y sostenibles, y fáciles de almacenar y transportar.

Estos carbones se pueden utilizar en combustión doméstica, calderas, barbacoas, calefacción de chimeneas, centrales eléctricas, etc.

Además, debido a su estructura microporosa única y su capacidad de súper adsorción. Se utiliza ampliamente en muchos campos, como el alimentario, farmacéutico, químico, metalúrgico, defensa nacional, agricultura y protección del medio ambiente.

Flujo de trabajo de la línea de producción de briquetas de carbón

Proceso de producción: Carbonización → Trituración → Mezclado y prensado → Conformación → Secado → Envasado

Coincidencia de equipos de línea de producción: Horno de carbonización continua → Molino de martillos → Mezclador de molino de ruedas → Máquina briquetadora de bolas de carbón → Secadora de cinta de malla → Máquina empacadora

Proceso principal de fabricación de bolas de carbón para barbacoa.

Las máquinas necesarias para el proceso de mecanizado y la información de parámetros correspondiente se enumeran en el siguiente orden.

Horno de carbonización continua

La humedad y los compuestos orgánicos volátiles de la madera se descompondrán y eliminarán, dejando atrás el carbón vegetal con alto poder calorífico y alto contenido de carbono.

- Modelo: SL-800

- Dimensión: 9*2,6*2,9 m

- Potencia: 22kw

- Capacidad: 300-400kg/h

- Peso: 9 toneladas

- Grosor de la carcasa de la máquina (acero): 11 mm

Máquina trituradora de carbón

Triture y muela aún más el carbón después de la carbonización para obtener partículas de carbón adecuadas para uso en barbacoa.

Específicamente, el polvo de carbón se hace para que tenga cierta granularidad y uniformidad para mejorar la eficiencia de combustión y la calidad del carbón.

- Modelo: SL-W-1300

- Potencia: 5,5 kw

- Capacidad: 300-500kg/h

- Diámetro interior: 1300 mm

Mezclador de pegamento

El propósito de una mezcladora de pegamento es mezclar partículas de carbón con un adhesivo o aglutinante. Luego, une las partículas de carbón para formar un bloque de carbón fuerte.

Esto ayuda a mejorar la estabilidad, durabilidad y moldeo del carbón, haciendo que el producto de carbón sea más fácil de almacenar, transportar y usar.

- Modelo: SL-M800

- Capacidad de entrada: 0,6m³

- Potencia: 3kw

- Diámetro interior: 800 mm

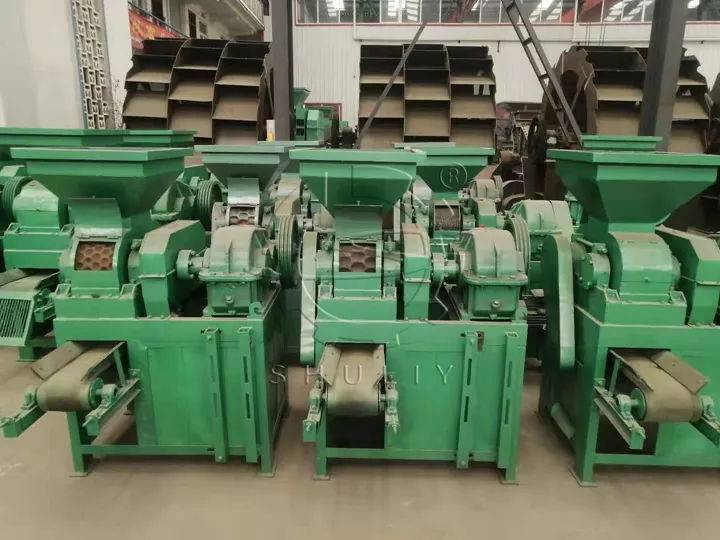

Máquina prensadora de bolas de carbón

Esta máquina presiona la mezcla y combinación de partículas de carbón procesadas junto con el aglutinante en bolas o trozos de carbón de cierta forma y tamaño.

Esto ayuda a mejorar aún más la estabilidad y durabilidad del carbón, haciendo que el producto de carbón sea más fácil de almacenar, transportar y usar. Su principio de funcionamiento se puede ver haciendo clic en el Máquina prensadora de bolas de carbón para la industria de las barbacoas..

- Potencia: 5,5 kw

- Capacidad: 1-2t/h

- Presión: 50 toneladas por vez

- Peso: 720 kg

Máquina secadora de cinta de malla

La función del secador en la línea de producción de carbón para barbacoas es secar el carbón moldeado. Esto puede mejorar la eficiencia de combustión, la calidad y la estabilidad de almacenamiento del carbón.

Empaquetadora de carbón para barbacoa

Máquinas de embalaje cuantitativas cuantificar y empaquetar con precisión productos de carbón vegetal que hayan sido procesados, moldeados y secados hasta un peso predeterminado.

Esto ayuda a garantizar la calidad constante de los productos de carbón en cada unidad de embalaje para facilitar el almacenamiento, transporte y distribución.

- Peso del embalaje: 20-50 kg por bolsa

- Velocidad de embalaje: 300-400 bolsas por hora

- Potencia: 1,7 kw

- Dimensión: 3000*1150*2550mm

Ventajas de la planta de procesamiento de carbón para barbacoa

La línea de producción de carbón para barbacoa tiene muchas ventajas que la hacen ideal para la producción eficiente y de alta calidad de productos de carbón vegetal.

- Productos de alta calidad: el parilla La línea de producción de carbón produce productos de carbón asegurando la uniformidad, estabilidad y eficiencia de combustión de las partículas de carbón a través de procedimientos de procesamiento fino.

- Utilización eficiente de la energía: el horno de carbón, la secadora y otros equipos adoptan la tecnología de utilización eficiente de la energía, lo que reduce el consumo de energía y los costos de producción.

- Coherencia y estandarización: La producción automatizada garantiza la consistencia y estandarización de los productos, mejorando la apariencia y la consistencia de la calidad de los productos.

- Embalaje conveniente: Las máquinas de envasado cuantitativo pueden envasar con precisión productos de carbón en unidades de peso o capacidad específicos para facilitar su almacenamiento, transporte y distribución.

Podemos proporcionar un diseño de línea de producción gratuito.

Cuando planee instalar una línea de producción de carbón para barbacoa, proporciónenos información detallada, que incluya:

- Tipo, tamaño y contenido de humedad de la materia prima.

- Tamaño de planta

- Capacidad del transformador

- Tipo y tamaño del producto terminado.

- Demanda de producción

Cuanto más detallado, mejor, ya que esto nos permitirá personalizar su equipo según sus necesidades específicas. También le proporcionaremos diagramas de planificación del sitio en 3D gratuitos.

Máquina de briquetas de carbón para línea de producción de combustible

La máquina briquetadora de carbón está diseñada para comprimir carbón o…

Carbón de leña de Shisha del acero inoxidable que hace la máquina para las tabletas de la briqueta de la cachimba

Las tabletas de carbón para cachimba producidas por shisha hidráulica de acero inoxidable...

Máquina hidráulica de briquetas de carbón Shisha para formar carbón

La máquina hidráulica de briquetas de carbón para shisha emplea tecnología hidráulica para...

Máquina giratoria para fabricar carbón Shisha para briquetas de narguile

La máquina rotativa para fabricar carbón para shisha es una máquina automática de doble prensa...

Máquina prensadora de bolas de carbón para la industria de barbacoas

Las máquinas prensadoras de bolas de carbón están diseñadas para comprimir sueltas…

Máquina de carbón en forma de panal para línea de producción de formación de briquetas

La máquina de carbón Honeycomb debe considerar el carbón bien procesado...

Horno de carbonización de elevación vertical para planta de fabricación de carbón vegetal

El horno de carbonización de elevación se utiliza para carbonizar madera o...

Horno de carbonización horizontal para procesamiento de carbón vegetal en trozos

El horno de carbonización horizontal es un tipo de equipo para…

Horno de carbonización continua para la producción de carbón vegetal de cáscara de arroz

El horno continuo de carbonización de carbón es un equipo ideal para secar…

Máquina trituradora de carbón para planta de moldeo de briquetas

La máquina trituradora de carbón, también conocida como molino mezclador,…

Producto caliente

Máquina de briquetas de carbón para línea de producción de combustible

Máquina briquetadora de carbón, también conocida como briquetadora…

Secador de carbón de briquetas para la producción de carbón Shisha en forma de panal

El secador de carbón de briquetas se refiere a la evaporación de…

Máquina hidráulica de briquetas de carbón Shisha para formar carbón

La máquina hidráulica de briquetas de carbón para shisha también es…

Máquina giratoria para fabricar carbón Shisha para briquetas de narguile

La máquina rotativa para fabricar carbón para shisha es una prensa doble...

Trituradora integral Máquina trituradora de madera de gran capacidad

La trituradora integral está diseñada para descomponer…

Máquina secadora de tambor rotatorio para planta de secado de aserrín en polvo

La secadora de tambor rotativo es un producto industrial común...

Secador de cinta de malla de briquetas de carbón para planta de secado continuo

El secador de cinta de malla de briquetas de carbón es un proceso continuo…

Horno de carbonización de elevación vertical para planta de fabricación de carbón vegetal

El horno de carbón se utiliza para carbonizar...

Máquina prensadora de bolas de carbón para la industria de barbacoas

La máquina prensadora de bolas de carbón es eficiente y conveniente...