Honeycomb Coal Machine For Briquette Forming Production Line

Coal briquette press machine | Honeycomb briquette machine

Honeycomb Coal Machine For Briquette Forming Production Line

Coal briquette press machine | Honeycomb briquette machine

Features at a Glance

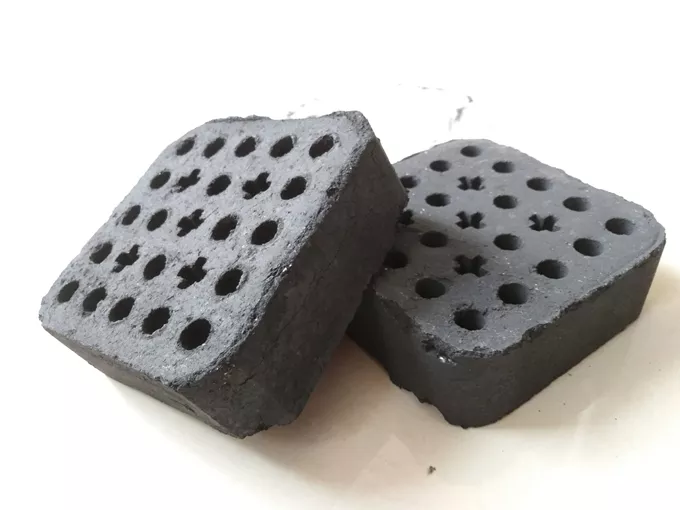

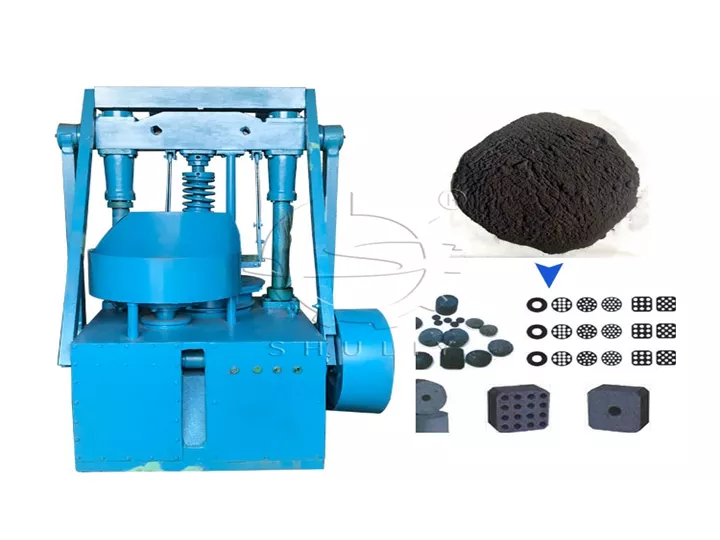

The Honeycomb coal machine is to regard the well-processed coal dust as raw material, through a series of processes, the charcoal carbonizes, presses, and processes coal or charcoal, and finally forms honeycomb-shaped briquettes.

It is also known as briquette forming machine because the holes on the coal briquette make it look like a honeycomb, and also because of these holes, the surface of the coal briquette expands, so the coal briquette can be easily and completely burned, reducing energy waste.

The coal briquette press machine has a wide range of applications, mainly used for industrial areas and home heating purposes. At the same time, this machine has a lot of molds, and you can change the molds easily per your special needs.

Raw materials and characteristics of honeycomb coal

The raw materials of honeycomb coal machines mainly include charcoal and coal. But, at first, the raw materials should be crushed into small pieces (a diameter < 1mm). These two kinds of raw materials are formed into honeycomb coal after specific processing technology, which has the following characteristics:

- Charcoal raw material characteristics: charcoal burns without smoke and odor, with high calorific value and long burning time. As the raw materials come from plants, charcoal is environmentally friendly and does not contain sulfur and other harmful components.

- Characteristics of coal raw materials: coal combustion produces soot and ash, relatively low calorific value, but because of its widespread and relatively low price, it is widely used as fuel.

Because it is not easy to mold coal powder and charcoal powder when their moisture content is high. The coal powder and charcoal powder must have proper bonding properties, otherwise, the coal powder and charcoal powder must be processed. The raw material can be mixed with 10% to 20% bonded coal to enhance its bonding property to achieve a better molding effect.

Different shapes and sizes of finished briquettes

We can make various styles of honeycomb coal molds. Specific parts that can be customized are the number of holes, diameter, and shape (e.g. square and hexagonal).

Users can change the mold of the coal briquette press machine to make different kinds of honeycombs with different numbers of holes and shapes.

Composition of honeycomb coal machine

The honeycomb briquette machine mainly consists of a body, power, coal feeding part, stamping part, and belt conveying part.

- Feeding part: It includes a rotary shaft, hopper, and mixer. These parts are used to mix and fill the coal powder into the mold.

- Machine body part: It consists of a press plate, machine base, and frame. The machine body is the main structure of the honeycomb coal machine to ensure the stability and sturdiness of the machine.

- Transmission part: This part includes the electric motor, pulley, gearbox, and transmission shaft. The electric motor drives the shaft to make the flat plate and turntable work to realize the process of coal powder pressing.

- Finished product conveying: After the honeycomb coal pressing is completed, the finished honeycomb coal will be transported out by a belt conveyor, which is convenient for collection and subsequent processing.

Operating principle of charcoal briquette making machine

Raw materials enter into the honeycomb coal machine after pretreatment such as reducing particle size and mixing. In the honeycomb machine, the carbonaceous material is subjected to a certain pressure and pressed into honeycomb coal briquettes of specified shapes and sizes.

Raw material preparation

Firstly, the pulverized coal or fine coal particles will be pre-treated, such as crushing, drying, and screening, to ensure the homogeneity and suitability of raw materials.

Mixing and blending

The pre-treated pulverized coal is mixed with appropriate binders, additives, etc. to form a homogeneous coal slurry. This slurry will be turned into raw material for honeycomb coal briquettes in subsequent steps.

Molding

The coal slurry is conveyed into the forming mold of the honeycomb coal machine. The structure of the forming mold and the arrangement of the holes will affect the shape and size of the final honeycomb coal briquettes. During the molding process, the coal slurry is subjected to pressure in the mold and gradually forms lumps of coal with a honeycomb structure.

Pressing and curing

In the forming mold, the coal slurry is pressed under high pressure to make it more compact. As the pressing proceeds, the moisture in the coal slurry is gradually squeezed out to form solid lumps of honeycomb coal.

Demolding and drying

The formed honeycomb briquettes are demolded from the molds and then sent to the drying equipment for drying. During the drying process, the water in the honeycomb briquettes will gradually evaporate, making the coal briquettes stronger and more stable.

Packaging and Storage

The dried honeycomb briquettes can be packaged and stored for future use. Honeycomb coal briquettes usually have high calorific value and combustion efficiency, which can be used as clean energy for heating, industrial combustion, and other fields.

Honeycomb coal briquette machine’s characteristics

- High density: As the honeycomb coal is pressed to form a regular honeycomb structure, it has a higher density, which is convenient for storage and transportation.

- High calorific value: The high calorific value of honeycomb coal makes it an efficient fuel that provides long-lasting combustion heat.

- Efficient production: the production speed of the honeycomb coal machine is fast, which can quickly meet the market demand.

- Versatility: Coal briquette machines can handle different types of raw materials. It can also make different shapes and sizes of honeycomb coal.

- High pressing force: the coal briquette press machine adopts the roller pressing principle, and the molded honeycomb coal briquettes are more compact and strong.

Parameters of coal briquette molding machine

Honeycomb coal with charcoal powder as raw material has a low blackness of smoke, which is good for environmental protection. The thermal efficiency of honeycomb coal is 20%-45% higher than that of coal burning, which is more energy-saving. Our company’s best sellers are the following two models of honeycomb coal machines.

| Model | Maximum diameter of charcoal | Power | Capacity | Weight |

| SL-120 | 120mm | 4.5kw | 6000Pcs/hour | 1.4t |

| SL-140 | 140mm | 7.5kw | 8000Pcs/hour | 1.5t |

What are the related charcoal extruder machines?

Similar machines to honeycomb coal machines are charcoal briquette machines, shisha charcoal machines, and charcoal ball press machines. All of these machines take charcoal powder and extrude it to form useful charcoal briquettes for energy utilization.

Our factory has been engaged in charcoal machinery processing and production for many years and has rich export experience. Our machines have been sent to Brazil, Kenya, Indonesia, Ukraine, Nigeria, Botswana, Turkey, Zimbabwe, and many other countries. If you are interested, we are your best choice. Please feel free to contact us.

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine, also known as a briquette extruder…

Shisha Charcoal Making Machine For Hookah Briquette Tablet

The stainless steel hydraulic shisha charcoal making machine is used…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

The hydraulic shisha charcoal briquette machine uses the power of…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Rotary shisha charcoal making machine is a double-press type automatic…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is used to press powdered raw…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Charcoal Grinder Machine For Briquette Molding Plant

The charcoal grinder machine, also known as a mixing mill,…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

This sawdust briquette machine is the main equipment to make…

Hot Product

BBQ Charcoal Packing Machine in Briquette Production Line

A charcoal bbq packing machine is a specialized…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is usually used to crush…

Multifunctional Shisha Hookah Charcoal Packing Machine For Sale

Hookah charcoal packing machine is a special equipment…

Charcoal briquette mesh belt dryer for continuous drying plant

Charcoal briquette mesh belt dryer is a continuous…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

Hydraulic shisha charcoal briquette machine is also a…

Charcoal Briquette Machine For Fuel Production Line

Charcoal briquette machine, also known as a briquette…

Wood Chipper Machine For Sawdust-making Plant

Wood chipper is an efficient wood processing machine…

Shisha Charcoal Making Machine For Hookah Briquette Tablet

The shisha charcoal making machine is also a…