Shisha Charcoal Production Line Hookach Briquette Making Machines

Shisha Charcoal Production Line Hookach Briquette Making Machines

The shisha charcoal production line transforms raw materials into high-quality hookah charcoal products through a series of technological steps such as raw material preparation, mixing, molding, drying, and packaging. The production capacity of this production line ranges from 1t/d to 10t/d, depending on the customization.

This shisha charcoal production line can process finished hookah charcoal in different sizes, round and square. Common sizes are round diameters 28, 30, and 33mm; square sizes 20*20mm, 22*22mm, and 25*25mm. In addition, the pattern of the finished product can be customized according to your requirements.

Raw materials for shisha charcoal production line

When making hookah charcoal, a variety of different biomass materials can be used for charring to give the flavor and aroma of the smoke. The following are some commonly used biomass materials: different types of wood, bamboo, coconut shells, firewood and herbs, fruit cores and husks, and tea waste.

All the above materials need to be carbonized and crushed first, and then meet the following standards before briquetting:

- We recommend that your material is less than 3 mm to make high-quality charcoal balls.

- The water content is around 10-25%, and the energy cost during the molding process is low. (When the water content is high, the charcoal balls are dense.)

- Add 5% of the binder, which can include starch, clay, mud, tar asphalt, molasses, resin, etc.

- Some wax, sodium nitrate, etc. can be added to help the charcoal burn.

Hookah finished product display and application market

In the Middle East, South Asia, and North Africa, at family gatherings and various celebrations, as well as in university towns in Europe and America, hookah is a common form of entertainment. Hookah charcoal-making machines are popular in the UAE, Arabia, Egypt, Pakistan, Morocco, Tunisia, the United States, etc.

- Different types of hookah charcoal can offer a variety of flavors, including woody, fruity, and herbal. Allowing consumers to choose the hookah charcoal that suits their tastes.

- High-quality water-smoked charcoal typically burns to produce less soot and hazardous substances, making it more environmentally friendly and healthier than traditional loose coal.

- By changing the mold, tablets of different shapes and colors (15-50mm) can be obtained, such as cube, square, rectangle, circle, diamond, triangle, cylinder, capsule, cone, convex, and concave. Words, trademarks, and logos can be embossed on the products.

Hookah charcoal production line workflow

The workflow of a water-smoked shisha charcoal production line usually includes the following key steps:

- Raw material preparation

- Mixing and blending

- Molding

- Drying

- Packaging

The level of automation in the shisha charcoal production line can be adjusted as needed to improve productivity and consistency.

Main machines of the shisha coal processing plant

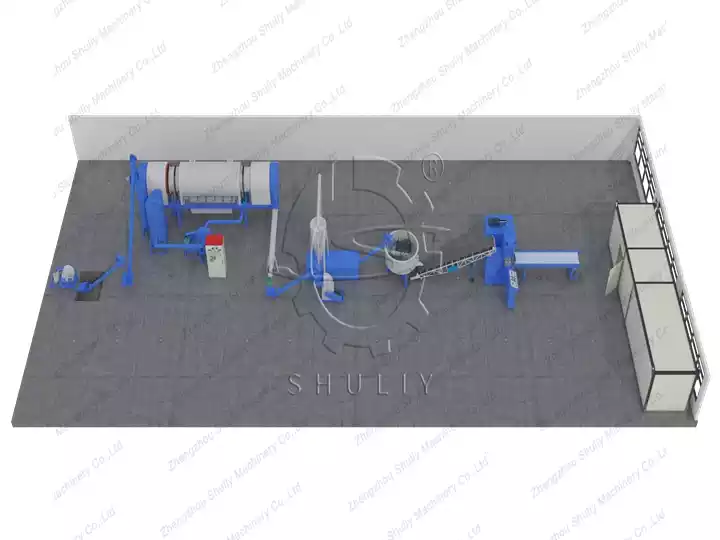

The shisha charcoal production line can be very flexibly matched according to the raw materials and production requirements. Shuliy Machinery can also provide customers with reasonable equipment solutions free of charge according to customer requirements.

Based on many years of experience in the production and sales of charcoal machines and the reasonable adoption of the use experience and feedback suggestions of many customers from different countries, the following basic shisha charcoal production lines are sorted out for customers’ reference and selection.

Raw material carbonization

This operation is to make charcoal powder that can process hookah charcoal. The raw material is first carbonized in this device and then connected to a hammer crusher to increase the contact area, which is convenient for the subsequent glue mixing operation.

Coal powder mixed with adhesive

After carbonized and crushed raw materials need to be mixed with the binder in a certain proportion, the mixing process ensures full mixing to avoid lumps or uneven mixing, thus improving the quality and uniformity of the finished product.

Shisha charcoal press machine

The rotary hookah charcoal machine presses the mixed raw materials into flakes or lumps for subsequent charring and packaging.

This operation can also be carried out by a hydraulic shisha charcoal machine and a stainless steel hookah charcoal machine.

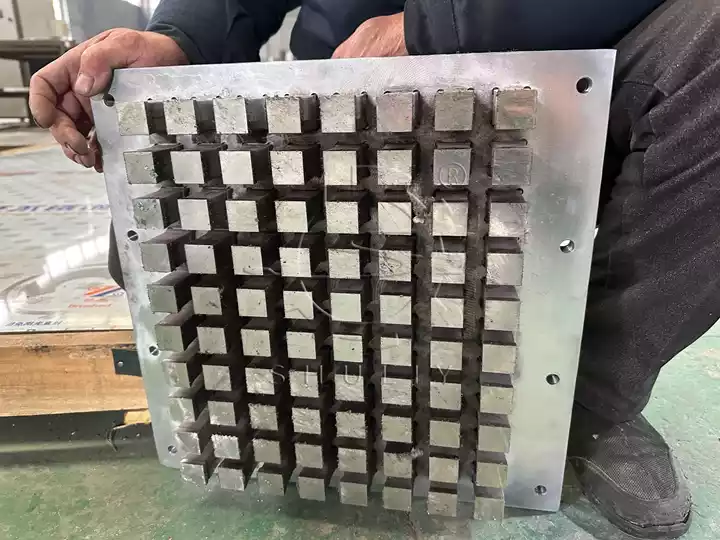

The following is a hydraulic hookah charcoal machine. The new design allows the mold to be easily disassembled to change to another shape, while previously the mold unit had to be completely removed before it could be replaced.

The machine is controlled by a PLC cabinet and all working states can be monitored. It is also equipped with a touch switch, and all processes are easy to operate. Any popular shape can be formed in one go. The production capacity is 5-6 batches/minute.

Hookah charcoal drying

Normally, there will be 25%-30% moisture after briquettes, which makes the charcoal unusable for direct sale or use.

At room temperature, it takes 2-5 days to dry. To solve this problem, we use this drying box, which can reduce the moisture to less than 3%.

According to our experience in charcoal drying, the temperature inside the dryer should be around 70-85 degrees, and the drying time depends on the moisture content of your charcoal!

Pillow packaging machine

Pillow wrapping machines automate the packaging of products to ensure freshness, consistency, and quality while improving packaging efficiency.

This helps manufacturers to deliver high-quality hookah charcoal products to the market and fulfill the needs of consumers.

For specific operations, please click the Hookah charcoal packing machine for shisha briquette bagging plant.

The packaging machine is usually equipped with a sorting machine in front of it. This equipment is widely used in the hookah charcoal packaging line to sort the charcoal blocks together for quick packaging.

It consists of two parts: the feeding part and the automatic distribution device, which will convey the hookah charcoal upward at a uniform speed.

During the conveying process, workers can pick out broken charcoal blocks from the feed tray. Usually, each batch of hookah charcoal blocks is packaged in groups of 10, and the number of charcoal blocks in each group can be customized.

Medium-sized Hookah charcoal processing line parameters

| No. | Item | Specification |

| 1 | Wood crusher | Model: SL-80 Power:37+7.5kw Capacity:1500-2000kg per hour |

| 2 | Screw conveyor | Power:2.2kw Length:4m |

| 3 | Rotary dryer | Model: SL-R1000 Power:7.5+7.5kw Capacity:800-1000kg per hour Dimension:φ1*10m |

| 4 | Screw conveyor | Power:2.2kw Length:4m |

| 5 | Distributor | Dimension:6.4*1.05*2.1m Power:4kw |

| 6 | Sawdust briquette machine | Model: SL-B50 Power:18.5kw Capacity:250kg per hour |

| 7 | Mesh conveyor | Length:7m |

| 8 | Carbonization furnace(3 sets) | Model: SL-C1500 Dimension:4.5*1.9*2.3m Capacity:4-5t per day, horizontal furnace |

Advantages and services

- The cutting, grinding, welding, and other processes of steel during machine processing are more precise, ensuring a long service life.

- Our engineering team can design factory drawings, production line matching, profit analysis, etc. according to the customer’s investment budget and production needs, and provide a full set of shisha charcoal production line solutions for different customers.

- Our factory has achieved mass production and has a certain amount of inventory, so the equipment delivery cycle is relatively short.

- To help customers achieve profitability as soon as possible, the company provides free adhesive formulas, various hookah charcoal processes, teaching videos, etc.

Successful cases

Our shisha charcoal production line equipment has always been loved and trusted by customers around the world and has been exported to many countries including Germany, France, the United Kingdom, the United Arab Emirates, Saudi Arabia, Egypt, India, Pakistan, Morocco, Tunisia, Canada, Australia and South Africa. The following is a display of the machine sent to Indonesia.

If you have any questions about this shisha charcoal production line and solution, please feel free to contact us and look forward to cooperating with you!

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine is designed to compress coal or…

Stainless Steel Shisha Charcoal Making Machine For Hookah Briquette Tablets

The hookah coal tablets produced by stainless steel hydraulic shisha…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

The hydraulic shisha charcoal briquette machine employs hydraulic technology to…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

The rotary shisha charcoal making machine is an automatic, double-press…

Charcoal Ball Press Machine For BBQ Industry

The charcoal ball press machines are designed to compress loose…

Honeycomb Coal Machine For Briquette Forming Production Line

The Honeycomb coal machine is to regard the well-processed coal…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Charcoal Grinder Machine For Briquette Molding Plant

The charcoal grinder machine, also known as a mixing mill,…

Hot Product

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…

Honeycomb Coal Machine For Briquette Forming Production Line

Honeycomb coal machine regards well-processed coal dust as…

Briquette Charcoal Dryer For Honeycomb Shisha Coal Production

Briquette charcoal dryer refers to the evaporation of…

Automatic Saw Mill Machine For Wood Recycling Plant

The saw mill machine cuts larger logs into…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using…

Automatic Wood Pallet Press Machine For Sale

Wood pallet press machine mainly process compressed wooden…

Multifunctional Shisha Hookah Charcoal Packing Machine For Sale

Hookah charcoal packing machine is a special equipment…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Rotary shisha charcoal making machine is a double-press…