Charcoal Ball Press Machine For BBQ Industry

Bbq charcoal machine | Coal briquette machine

Charcoal Ball Press Machine For BBQ Industry

Bbq charcoal machine | Coal briquette machine

Features at a Glance

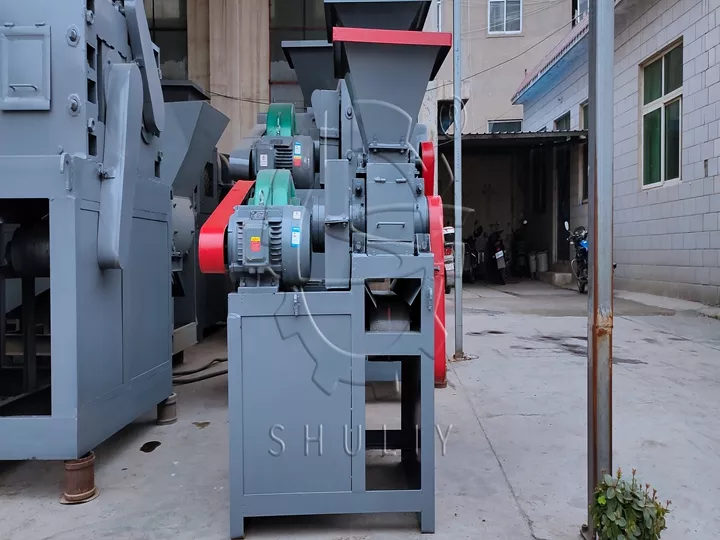

The charcoal ball press machines are designed to compress loose charcoal, coal powder, mineral powder, and various other powders into regular, dense spherical, oval, ovoid, egg-shaped, and pillow-shaped briquettes. These machines find extensive applications in refractories, power plants, metallurgy, the chemical industry, energy, transportation, fuel processing, heating, and other industries.

With the ability to achieve a molding rate of 98% or higher through hydraulic and roller pressure, the resulting molded particles are not only dense but also have a tidy appearance, making them easy to transport and store.

Our customers usually buy this machine to make BBQ charcoal balls for sale. We have different models to meet different output requirements. By changing the rolls of the ball press, different shapes and sizes of briquettes can be produced.

Raw materials processed by charcoal ball press machine

The charcoal ball press machine is capable of processing a variety of powdered materials, including coal powder, charcoal powder, various metallurgical furnace dry powders, metal magnesium dry powder, white lime dry powder, iron powder, coking coal, aluminum, iron, tin oxide, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, and many other types of powdered substances.

It can also handle different kinds of animal feeds, fertilizers, waste materials, and residues. The recommended humidity level for raw charcoal is about 30%, and the size should be under 5mm. If you’re using lump charcoal or coconut charcoal to create briquettes, you’ll need to grind it into powder using a charcoal crusher machine.

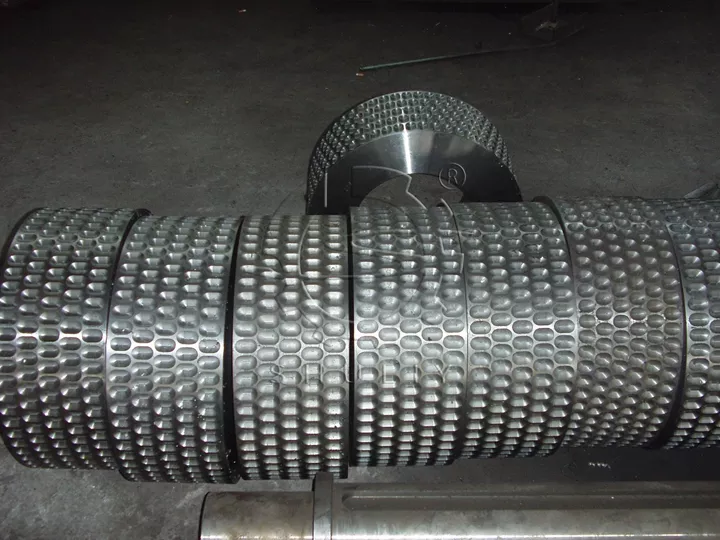

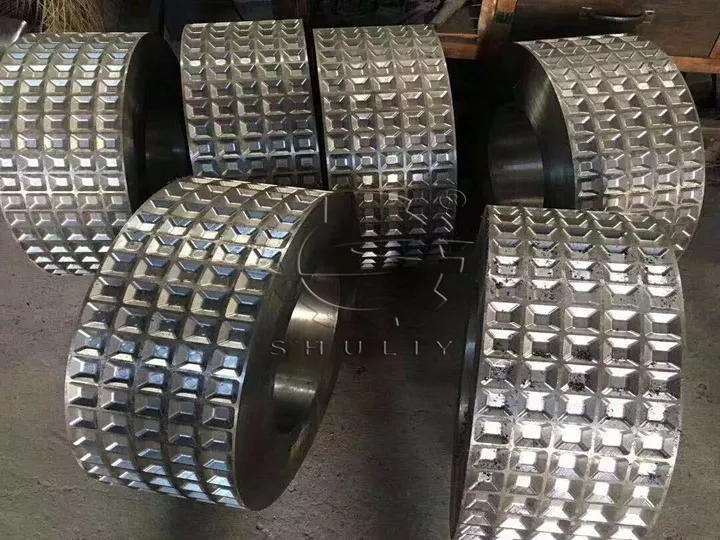

Customizable molds for various charcoal ball presses

The pressure roller is a crucial part of the charcoal ball press machine, typically found in pairs within the machine. Due to the high pressure and friction with the charcoal powder and particles, it is also a delicate component. Therefore, it requires regular replacement.

We ensure that all rollers are heat-treated to improve their hardness and resistance to wear. Additionally, we can customize the rollers to meet the specific shape and size requirements of our customers.

BBQ charcoal machine finished products

Finished charcoal ball briquettes can be used in several industries. They can be pillow shapes, oval spheres, egg shapes, diamond shapes, monograms, heart star shapes, and so on.

Barbeque charcoal-making machine technical parameters

Shuliy produces several different models of charcoal ball press machines, of which, according to business data, the small and medium-sized models are more popular, with the following four models selling more.

| Model | 290 | 360 | 400 | 500 |

| Capacity(t/h) | 2-3 | 4 | 6 | 10 |

| Powder(kw) | 5.5-7.5 | 7.5 | 11-15 | 18.5-22 |

| Roller material | 65Mn | 65Mn | 65Mn | 65Mn |

| Diameter of finished products(mm) | 30-60 | 30-60 | 30-60 | 30-60 |

Workflow of BBQ charcoal briquettes making plant

Raw material processing

First of all, the raw materials need to be pre-treated, such as crushing, screening, or mixing. Make sure the particle size and humidity of the raw materials meet the requirements of the ball press.

Adding binder

To improve the firmness of the ball, sometimes it is necessary to add a binder to the raw material. These binders can be natural, such as starch, honey, etc., or chemically synthesized.

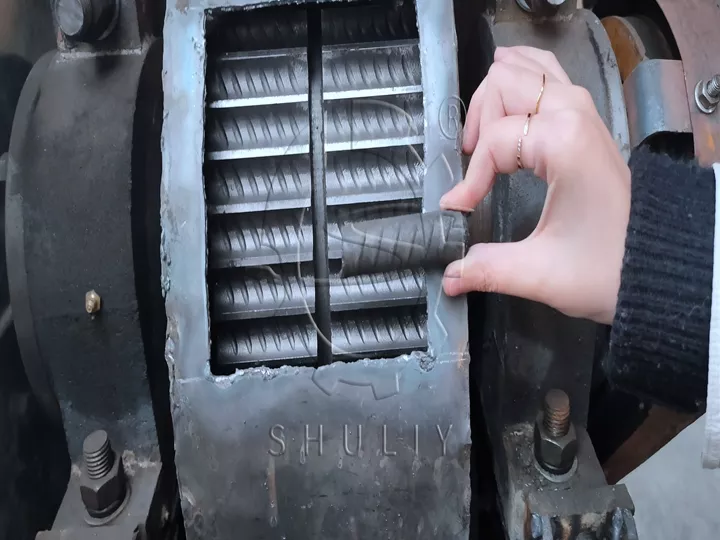

Ball pressing and molding

The pre-treated raw materials are put into the feed opening of the charcoal ball press machine, and the roller applies a certain pressure to press the raw materials into a spherical shape.

Cooling and packing

After the pressed balls are cooled, they can be packed for easy storage and sale.

Working principle of coal balls pressing machine

- Start the charcoal press machine, the motor drives the belt to the reducer and then drives the main shaft through the coupling.

- A pair of open gears ensures the synchronized operation of the two rollers. At the same time, the material from the storage bin through the quantitative equipment evenly into the molding hopper.

- During the forming process of the BBQ charcoal ball pressing machine, the pressure gradually increases and finally reaches the maximum value at the center line of the machine rollers.

- Then after the material passes the line, the molding pressure decreases rapidly, and the ball is successfully removed and finished molding.

Factory for making charcoal briquette extruder

Shuliy has a strong production capacity, we have enough machines in stock and an efficient production method, which can ensure a timely supply of bbq charcoal briquetting machines to customers.

Our factory also produces other charcoal molding machines such as shisha charcoal-making machines, charcoal briquette extruder machines, etc.

BBQ charcoal machine sold to many countries

We have rich experience in charcoal production and have helped to produce popular charcoal production equipment in Peru, Tanzania, USA, United Arab Emirates, Kenya, South Africa, the Philippines, Indonesia, Zambia, Nigeria, India, Paraguay, Malaysia, Russia, Uganda, Ghana, Sri Lanka and other countries. Below are the pictures of the ball press machine shipment.

Features of BBQ charcoal briquette press machine

- The production scale can be adjusted from 500 kg/h to 10 t/h, making it ideal for both small and large investment projects.

- Its simple structure allows for operation by personnel with little experience.

- The machine can process barbecue charcoal briquettes in various sizes and shapes.

- The final product features uniform density, stable quality, and consistent ball size.

- This charcoal ball press machine is built to national standards and boasts a long service life.

Shuliy Machinery offers a comprehensive solution for biomass charcoal production, covering everything from consultation and design to planning, manufacturing, installation, and future upgrades for customers worldwide. We are committed to delivering the highest quality solutions tailored to your specific needs and circumstances. Don’t hesitate to reach out to us!

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine is designed to compress coal or…

Stainless Steel Shisha Charcoal Making Machine For Hookah Briquette Tablets

The hookah coal tablets produced by stainless steel hydraulic shisha…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

The hydraulic shisha charcoal briquette machine employs hydraulic technology to…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

The rotary shisha charcoal making machine is an automatic, double-press…

Honeycomb Coal Machine For Briquette Forming Production Line

The Honeycomb coal machine is to regard the well-processed coal…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Charcoal Grinder Machine For Briquette Molding Plant

The charcoal grinder machine, also known as a mixing mill,…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

Hot Product

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…

Automatic Heat Shrink Film Charcoal Briquette Packing Machine

Shrink charcoal briquette packing machines are well suited…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The charcoal making furnace is used for charring…

Wood Chipper Machine For Sawdust-making Plant

The wood chipper machine is designed to break…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Rotary shisha charcoal making machine is a double-press…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives…

Horizontal Carbonization Furnace For Lump Charcoal Processing

Lump charcoal making machine is a kind of…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using…