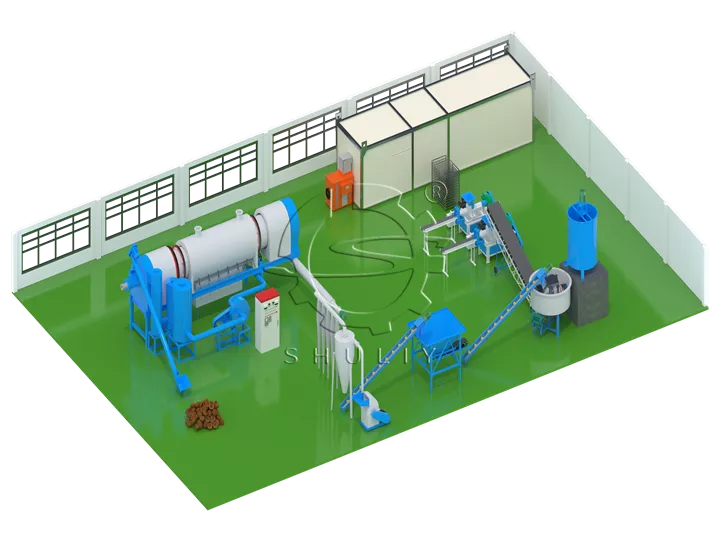

Biomass Carbonization And Charcoal Briquette Processing Plant

Biomass Carbonization And Charcoal Briquette Processing Plant

Charcoal briquette processing plant utilizes a variety of low-cost biomass raw materials such as logs, bamboo, etc., through the process of crushing, charring, mixing, pressing, drying, and other steps, and ultimately made into dense, high-energy-density solid fuels.

To provide you with high-quality customized services, please provide the following detailed information: site size, raw material type and size, raw material moisture, finished product type, finished product size, and output requirements. We will provide you with production line drawings and site planning drawings free of charge.

This production line belongs to carbonization first and then molding, which is the main difference from the traditional charcoal production line which is molding first and then carbonization.

How to get charcoal feedstock for making briquettes

The raw materials used to make briquettes are usually coal dust and charcoal powder. Alternatively, charcoal can be made from biomass materials such as waste wood, twigs, coconut shells, rice husks, bamboo, and palm shells.

If you have sufficient raw materials, you can directly use the carbonization furnace to produce charcoal to save the cost of purchasing finished charcoal. We can use a variety of optional raw materials.

Finished product of briquette making production line

The finished briquette charcoal has various advantages, such as high calorific value and efficient combustion, low humidity, uniformity, low ash, and easy storage and transportation.

These briquettes can be used for Arabic smoking, barbecue, home heating, cooking, metal heating and melting, boiler heating, industrial boilers, etc.

Charcoal briquette processing plant workflow

This charcoal briquette processing plant is a kind of charcoal-making production line, only the molding equipment is different. We also sell barbecue charcoal, shisha charcoal, and honeycomb coal production lines. Please contact us for more details and customization of production lines.

The charcoal briquette processing plant needs to go through a series of processes: coal powder preparation → raw materials mixing → pressing and molding → drying → cooling → quality control and packaging.

- Prepare raw materials: Screening, and crushing charcoal blocks or coal materials into fine powder.

- Mixing process: Mixing coal/charcoal powder with binder and some other additives (if required).

- Extrusion process: The mixed charcoal powder is balled/extruded into specific shapes using a charcoal machine.

- Drying process: Sun drying or using a box drying room.

- Packaging process.

The above process needs to be completed with the following important pieces of equipment:

Charcoal carbonization furnace

Continuous carbonization furnace plays a vital role in briquettes by removing volatile substances from the materials, increasing the calorific value of the finished products, reducing the moisture content, and so on.

The continuous carbonization furnace requires the raw material particle size to be less than 50mm, the thickness to be less than 3mm, and the humidity to be less than 15% to ensure higher production efficiency.

If the size of your raw materials is large, we recommend you use a hoisting carbonization furnace. In addition, charring sawdust, fruit shells, and other crushed materials, for the lower budget or smaller production capacity of the plant, we also recommend the following rotary carbonization furnace.

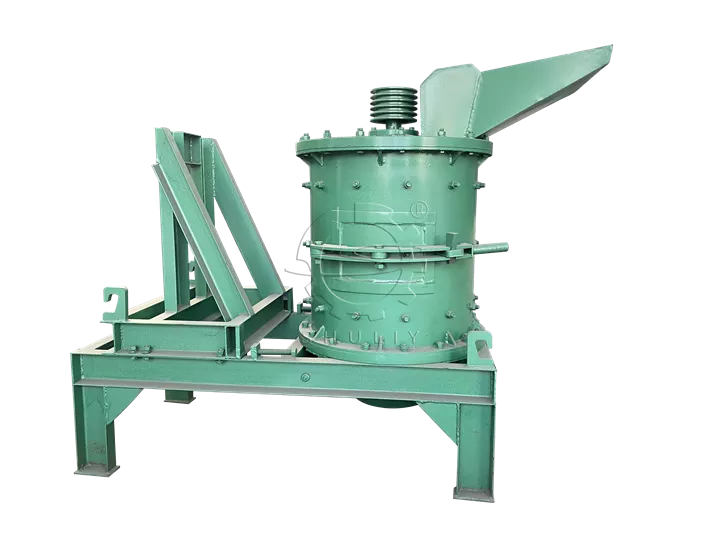

Coal crushing machine

The coal crusher crushes raw coal lumps into finely powdered coal for subsequent mixing and molding steps. This device can also be replaced by a hammer mill.

It also increases the surface area, which helps the binder mix better with the coal powder and improves the stability and combustion performance of the briquettes.

Stirring and glue mixing

The glue mixing operation is one of the key steps in the charcoal briquette processing plant for mixing the coal powder and the binder.

This ensures that the binder is uniformly dispersed throughout the coal bar mixture to ensure that each bar has the same bonding properties and stability.

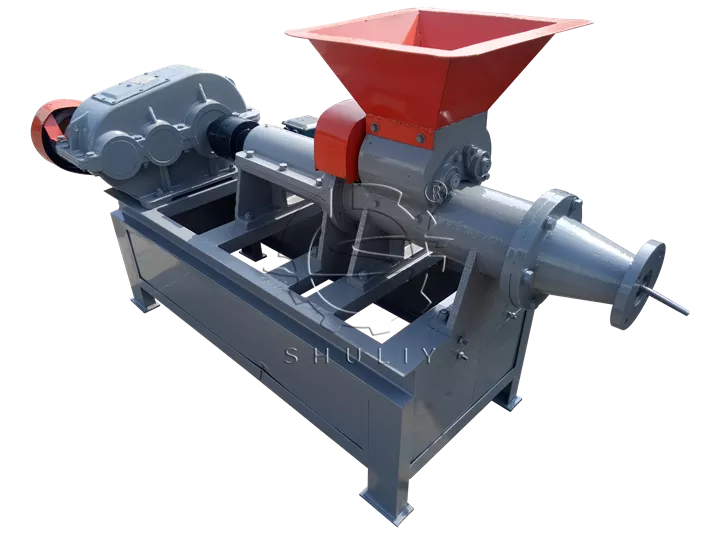

Charcoal briquette extruder machine

This machine is the key equipment in a charcoal briquette processing plant, which mixes and presses the coal powder and binder to make the coal bar.

Improve the denseness of the coal rods, making them more solid and stable, not easy to disintegrate or break.

About the specific introduction of the charcoal briquette press machine and how it works, you can learn by clicking this article: Charcoal briquette machine for fuel production line.

Finished product drying

The drying room size can be customized and the installation is flexible. You can choose the appropriate equipment according to the size of your factory site.

Charcoal briquettes packaging

To prevent moisture and facilitate transportation, it is best to package the charcoal briquettes.

According to the characteristics of the finished products and experience, this production line needs to be equipped with a heat shrink film packaging machine.

Charcoal briquette forming molds display

According to the customer’s different needs for the shape and size of the finished product, we can provide different molds to achieve. These molds and wearing parts can be free of charge when purchasing the charcoal briquette processing plant.

Coal briquette making machine line project case

We have cooperated with many countries and our charcoal briquette processing plant machines have been sent to Slovakia, Zambia, Malaysia, Congo, Lebanon, Somalia, Algeria, Indonesia, etc.

After the customer from Uganda purchased the biomass carbonization briquette production line, our engineers went to the local area to install it. The following is the on-site feedback on the machine’s operation.

Advantages of charcoal briquette processing plant

- High efficiency and labor-saving: The enlarged screw pitch of the charcoal briquetting machine helps to increase the feed amount, thereby greatly improving the output. The smallest model has an output of 600kg/h.

- High quality of finished products: The improved structural design of the molding cylinder greatly reduces the friction between the briquette extruder machine and the raw materials and improves the finished production density.

- Reasonable design and energy saving: The electric heating device is automatically controlled and the material humidity is randomly adjusted to ensure the stability of material molding. Automatic conveyors and automatic cutting devices are optional to directly produce the specified length.

- Strong durability: The main components of the machine are made of specially treated wear-resistant materials and heavy-duty design; the oil-immersed lubrication system ensures a long service life.

Want to start a coal or charcoal briquette processing plant business? Planning to build a complete full-size charcoal briquette factory, but don’t know which charcoal making machine is right for you? Please feel free to contact us for more information about machines for making charcoal and briquettes. We are always at your service!

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine, also known as a briquette extruder…

Shisha Charcoal Making Machine For Hookah Briquette Tablet

The stainless steel hydraulic shisha charcoal making machine is used…

Hydraulic Shisha Charcoal Briquette Machine For Coal Forming

The hydraulic shisha charcoal briquette machine uses the power of…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Rotary shisha charcoal making machine is a double-press type automatic…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is used to press powdered raw…

Honeycomb Coal Machine For Briquette Forming Production Line

The Honeycomb coal machine is to regard the well-processed coal…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Charcoal Grinder Machine For Briquette Molding Plant

The charcoal grinder machine, also known as a mixing mill,…

Hot Product

Charcoal Briquette Machine For Fuel Production Line

Charcoal briquette machine, also known as a briquette…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment…

Large Hammer Mill Crusher in Sawdust-making Plant

Hammer mill crusher uses hammer blades to shred…

Horizontal Carbonization Furnace For Lump Charcoal Processing

Lump charcoal making machine is a kind of…

Shisha Charcoal Making Machine For Hookah Briquette Tablet

The shisha charcoal making machine is also a…

Wood Crusher Machine For Making Sawdust

The wood crusher machine plays a crucial role…

Feed Pellet Mill Machine For Animal Livestock

Feed pellet mill is used for making animal…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

Biomass charcoal making machine can extrude and shape…

BBQ Charcoal Packing Machine in Briquette Production Line

A charcoal bbq packing machine is a specialized…