Automatic Heat Shrink Film Charcoal Briquette Packing Machine

Thermal shrink wrapping machine | Biomass briquette packaging machine

Automatic Heat Shrink Film Charcoal Briquette Packing Machine

Thermal shrink wrapping machine | Biomass briquette packaging machine

Features at a Glance

Heat shrink film charcoal briquette packing machines are well suited for wrapping wooden sticks. The machine shrinks the film by wrapping it around the outer surface of the sticks and applying a heat source to shrink the film. This firmly wraps the product and achieves the purpose of packaging.

The packaged items are beautiful and neat and can be sold directly. It is generally used to pack the machine biomass briquettes made by a sawdust briquette-making machine.

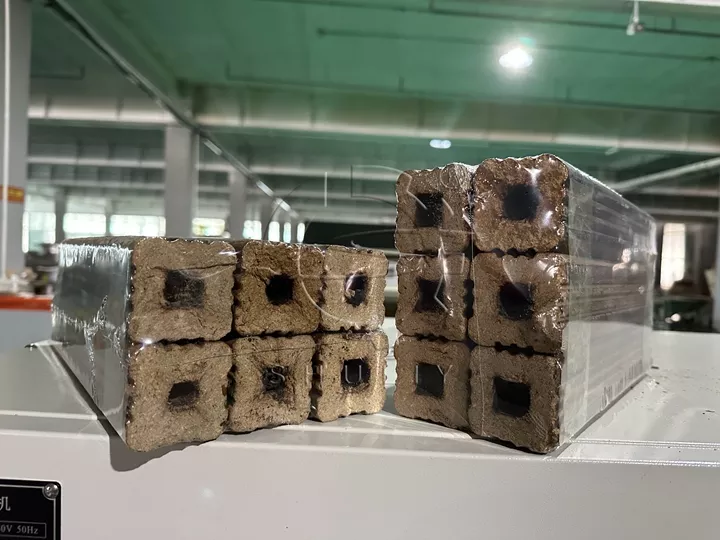

Shrink charcoal briquette packing machine finished products

The characteristics of the finished heat shrink film packaging machine reflect its value in terms of protection, aesthetics, and market communication for a wide range of product packaging needs. Below is a picture of the finished charcoal briquette sticks from the heat shrink film charcoal briquette packing machine:

Packaging scope of sawdust briquette packaging machine

Heat shrink film wrapping machine is a widely used equipment in the packaging industry, which uses heat shrink film to package products under a tightly fitting film, and then shrinks the film by heating it for protection, sealing, and aesthetics. The uses of heat shrink film charcoal briquette packing machines are varied, mainly including the following aspects:

The food industry, beverage industry, cosmetics products industry, pharmaceutical industry, daily necessities industry, industrial products industry, electronics industry, toys industry, and so on.

Overall, heat shrink film packaging machines have important applications in many industries to protect products, enhance appearance, and increase packaging branding through tight wrapping and heat shrinking.

Shrink film biomass briquette packing machine working process

The entire process is automated, with a control system precisely controlling each step. The workflow of a heat shrink film charcoal briquette packing machine protects the product, enhances its cosmetic appeal, and provides a sealing effect by tightly wrapping a wide range of different types of products.

Product feeding

The product to be wrapped enters the working area of the wrapping machine through the feeding system. This can be done manually by placing or through an automatic conveyor belt.

Hot shrink film preparation

A roll of heat shrink film is pulled from the reel where the film will be used to wrap the product. Heat shrink film is a plastic film that shrinks when exposed to heat.

Film Sealing and Cutting

The charcoal briquette packing machine uses a sealing and cutting device to close the heat-shrink film into a suitably sized segment to form an open bag. This pouch is often referred to as a “baggie”.

Product Loading

The film-sealed and cut heat shrink bag sleeve is opened and the product is precisely placed in it. This can be done manually or by an automatic filling system.

Film Shrinkage

After the product in the bag sleeve is wrapped, the entire bag is fed into the shrink zone. In the shrinking area, the heat shrink film in the bag sleeve is exposed to a high-temperature environment, causing the film to shrink rapidly and tightly wrap around the product.

Cooling and Curing

After the film shrinks, the heat shrink film in the bag sleeve cools and cures rapidly, securing the product in a tight package.

Outfeed and Collection

After the completion of shrinkage, the product is sent to the outfeed area, usually via a conveyor belt or other device for collection or further processing.

Main parameters of thermal shrink packing machine

The following are some important parameters of the Shuliy charcoal briquette packing machine’s top-selling model:

| Model | SL-450L |

| Dimension | 1630*900*1470mm |

| Power | 3KW |

| Packing speed | 15-30 bags/min |

| Maximum package size | L+H<500mm, W+H<400mm |

| Air pressure | 0.5MPA |

| Applicable shrink film | POF/PE |

| Weight | 280kg |

| Voltage | 220V, 50/60HZ |

Differences between sawdust briquette packing and other packaging machines

- The charcoal briquette packing machine uses transparent film to package items.

- The way of working is heating and shrinking for packaging. Others use bags and seal the bags.

- Heat shrink biomass briquette packaging machine is widely used for products of various shapes and sizes and can flexibly adapt to different packaging needs.

- The high degree of automation does not require many people to operate.

Advantages of heat shrink packing machine

- Protective packaging: Heat shrink film packaging provides effective protection against contamination, dust, moisture, ultraviolet rays, etc., and extends the shelf life of the product.

- Strong sealing: Heat shrink film can tightly fit the product and form a sealed barrier, effectively preventing leakage and the influence of external factors.

- Attractive appearance: Heat shrink film can make the appearance of packaged products more attractive, improving brand image and market competitiveness.

- Wide adaptability: Heat shrink film charcoal briquette packing machine is suitable for different shapes, sizes, and types of products, from food to industrial products.

- Customized packaging: Heat shrink film can be customized printed to add product information, brand logos, barcodes, etc. to the package to increase product recognition.

- Enhancement of quality: By tight packaging, products are less prone to collision and damage during transportation and storage, maintaining high quality.

- Multifunctionality: The heat shrink film charcoal briquette packing machine can be applied to a variety of packaging needs, such as single-product packaging, multiple-product packaging, multi-layer product packaging, etc.

Conclusion

The finished products packaged by this machine usually come from the wood sawdust briquette machine. You can view more by clicking Sawdust Briquette Machine For Biomass Charcoal Processing Line. In the charcoal industry, we produce different types of packaging machines for different charcoal products, such as hookah charcoal packaging machines and quantitative BBQ charcoal packaging machines. If you are interested, please feel free to contact us.

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine is designed to compress coal or…

Stainless Steel Shisha Charcoal Making Machine For Hookah Briquette Tablets

The hookah coal tablets produced by stainless steel hydraulic shisha…

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

The rotary shisha charcoal making machine is an automatic, double-press…

Charcoal Ball Press Machine For BBQ Industry

The charcoal ball press machines are designed to compress loose…

Honeycomb Coal Machine For Briquette Forming Production Line

The Honeycomb coal machine is to regard the well-processed coal…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

BBQ Charcoal Packing Machine in Briquette Production Line

The BBQ charcoal packing machine is a device specialized in…

Hot Product

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using…

Wood Chipper Machine For Sawdust-making Plant

The wood chipper machine is designed to break…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Stainless Steel Shisha Charcoal Making Machine For Hookah Briquette Tablets

The shisha charcoal making machine is also a…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is efficient and convenient…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The charcoal making furnace is used for charring…

Pallet Block Machine For Wooden Packaging Production Plant

The standard sizes of wood blocks that can…

BBQ Charcoal Packing Machine in Briquette Production Line

A charcoal bbq packing machine is a specialized…