Automatic Wood Pallet Press Machine For Sale

Sawdust pallet press machine | Compressed wood pallet machine

Automatic Wood Pallet Press Machine For Sale

Sawdust pallet press machine | Compressed wood pallet machine

Features at a Glance

The wood pallet press machine is our featured product, mainly processing compressed wooden pallets, the finished product has a strong load-bearing capacity and is widely used in the storage and transportation industry. The size, and shape of the wooden pallet are determined by the mold of the machine. Common processing sizes are 1200*1000mm and 1200*800mm, about 15 pallets can be processed in one hour.

What materials can make press wooden pallets?

The raw materials of the wood pallet press machine are roughly the same as the pallet block press machine, mainly including sawdust, wood shavings, rice husk, and other materials containing wood fiber such as coir. In addition, the raw material needs to be mixed with glue, usually urea-formaldehyde resin glue, before entering this machine.

How does a wooden pallet making machine work?

The wood pallet machine processes the raw wood material into the desired wooden pallets through the steps of loading, molding, compressing, cooling, and quality checking of the raw material. The machine is equipped with two sets of feed bins that can be replaced by each other during the working process. This automated production process improves productivity and also reduces wood waste, which is in line with the concept of environmental protection and sustainable development.

Raw material preparation

First of all, the wood raw materials need to be prepared and processed. These raw materials are usually waste wood, wood shavings, wood chips, etc., which are cut, crushed, and cleaned for subsequent processing use.

Raw material loading

The treated wood particles are loaded into the feeding system of the wood palletizer, usually using a feed hopper or a conveyor belt.

Molding and Compression

The raw material is fed into a specially designed molding area, usually a mold or combination of molds. Here, the raw material is subjected to high pressure and temperature to form the desired shape of the wood pallet within the mold. Adhesives may be added to ensure a tight bond between the wood particles.

Cooling and Curing

Once the wood particles have been compressed into the desired shape, the wood pallet is cooled and cured within the molding area to ensure that the wood retains its structure once the shape has stabilized.

Working Video of wood pallet press machine

Wooden pallet finished products show

Wooden pallets are flat structures used to transport, store, and support goods and are strong, durable, and reusable. The finished form of wood pallets can come in a variety of sizes and designs to suit different goods and industry needs.

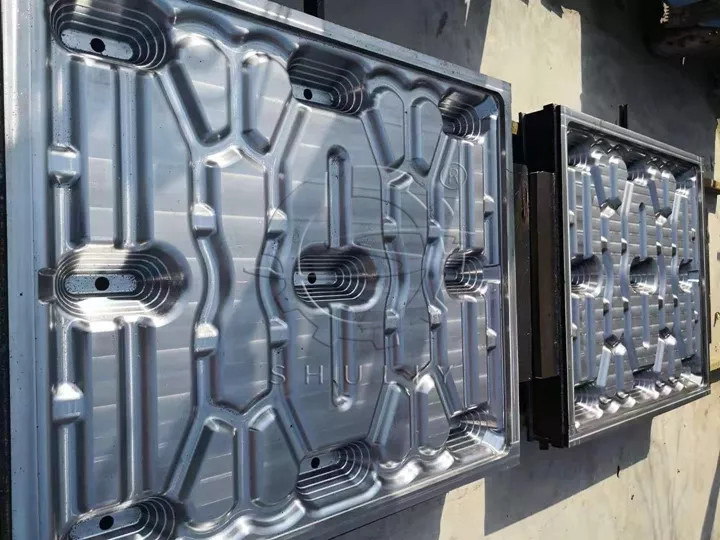

Below are some wood pallet press machine molds from our factory:

These are some of the common types of finished wood pallets, and there are many other shapes, sizes, and designs that can be custom-fabricated to suit specific goods and needs.

Wooden pallets play a key role as an important piece of logistics equipment in a variety of industries, facilitating and supporting the transportation and storage of goods.

Presswood pallet making machine technical parameters

To meet your requirements, we can make different models of wood pallet press machines. According to the sales data, the more popular model is SL-1000, and its specific parameters are as follows:

- Model: SL-1000

- Dimension: 1.9*1.3*4m

- Pressure: 1000tons

- Power: 15kw

- Weight: 21000kg

- Capacity: Produce one pallet needs 4-5 minutes (can control yourself )

Features of compressed sawdust pallet machine

There are many advantages of using the wood pallet press machine as a production machine for wooden pallets, some of the main advantages are listed below:

- Efficient production: The Wood Pallet Machine uses an automated production process to efficiently produce large quantities of wooden pallets, reducing labor costs and increasing production efficiency.

- Consistency and precision: A wooden pallet machine can ensure that the size and quality of each produced wooden pallet are consistent, which avoids human error and improves product precision.

- Customized production: Wood pallet machines usually have flexible settings to customize the production of wood pallets according to different sizes, shapes, and design requirements.

- Quick adjustment: Wood pallet machines usually have quick mold changes and adjustments to adapt to different production needs.

- Reduced damage rate: Due to the consistent quality of wooden pallets produced by wood pallet machines, the damage rate of goods during transportation and storage can be reduced.

Overall, the use of this machine allows for efficient, accurate, and sustainable production of wood pallets in the production process, providing reliable support for logistics operations and cargo storage. These advantages make the wood pallet press machine an indispensable and important piece of equipment in the wood pallet manufacturing industry.

Sawdust Briquette Machine For Biomass Charcoal Processing Line

This sawdust briquette machine is the main equipment to make…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

The rotary drum dryer machine is commonly used to evaporate…

Wood Crusher Machine For Making Sawdust

The wood crusher machine is used to recycle waste wood…

Automatic Saw Mill Machine For Wood Recycling Plant

The automatic saw mill machine is a mechanical device used…

Wood Debarker Machine Timber Log Peeling Equipment

The wood debarker can efficiently strip the bark from the…

Large Hammer Mill Crusher in Sawdust-making Plant

The hammer mill crusher uses hammer blades to shred and…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is a multi-functional processing equipment, usually used…

Feed Pellet Mill Machine For Animal Livestock

The feed pellet mill machine is a kind of equipment…

Presswood Pallet Production Line For Wood Recycling Plant

The presswood pallet production line is dedicated to making molded…

Automatic Compressed Wood Pallet Blocks Production Line For Sale

The wood pallet blocks production line uses waste wood chips,…

Hot Product

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The charcoal making furnace is used for charring…

Feed Pellet Mill Machine For Animal Livestock

Feed pellet mill is used for making animal…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is usually used to crush…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment…

Wood Crusher Machine For Making Sawdust

The wood crusher machine plays a crucial role…

Automatic Heat Shrink Film Charcoal Briquette Packing Machine

Shrink charcoal briquette packing machines are well suited…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Charcoal briquette mesh belt dryer for continuous drying plant

Charcoal briquette mesh belt dryer is a continuous…

Honeycomb Coal Machine For Briquette Forming Production Line

Honeycomb coal machine regards well-processed coal dust as…