Presswood Pallet Production Line For Wood Recycling Plant

Compressed wood pallet production line | Automatic wooden pallet making machines

Presswood Pallet Production Line For Wood Recycling Plant

Compressed wood pallet production line | Automatic wooden pallet making machines

The presswood pallet production line is dedicated to making molded wood pallets by using wood chips, shavings, sawdust, and so on. It is for the reuse of all kinds of waste wood, which belongs to the protection of the environment. Manufacturing wooden pallets is mainly used for stacking, loading, and transporting goods.

Customers can choose the machine according to production capacity. By changing different molds, this machine can produce wood pallets of different specifications, sizes, and shapes. These pallets have a strong structure and are waterproof (no cracking in water for 48 hours, no cracking in wind and sun). When made from quality materials, pressed wood pallets can last for several reuse cycles of 20-30 trips before replacement.

Raw materials of presswood pallet production line

The presswood pallet production line mainly produces presswood pallets by compression molding with sawdust, shavings, wood chips, straw, and coconut fiber (coir) as raw materials. Other fiber-rich materials are also suitable, such as straw (wheat/corn), waste paper, bamboo, palm trees, softwood, bagasse, miscanthus, and so on.

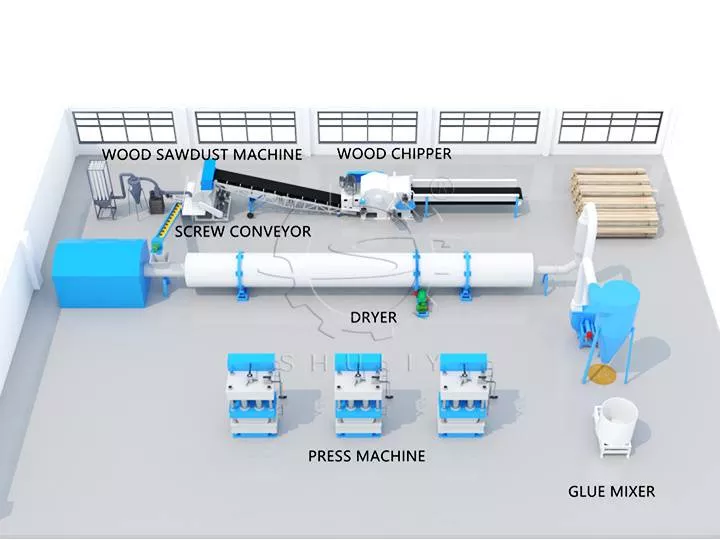

Workflow of compressed wood pallet making line

If you want to invest in a high-yield wood recycling program or a pallet-making plant, we can make your one-stop solution. A complete presswood pallet production line should include the following range of wood processing equipment: wood chipping machine → hammer mill crusher → dryer machine→ glue mixer → wood pallet press machine.

To get the wood pallets that meet the needs of the majority of users, we are equipped with the appropriate model of each piece of equipment in the entire production line, saving customers the trouble of choosing the model of the machine.

Drum wood chipper: crush wood logs into wood chips

The drum-type wood chipping machine installs knife rollers and blades inside a cylindrical rotating drum. The blades cut wood, bamboo, straw, etc. into fine particles or thin slices.

Model: SL-216

Input size: 230*500mm

Knife roller speed: 590r/min

Size of finished product: 50*50mm

Power of Main Motor: 55kw

Weight: 4300kg

Capacity: 5t/h

Hammer mill crusher: crush wood chips into sawdust

Hammer mills use hammer blades to chop and pulverize wood chips to form sawdust.

Model: SL-500

Input size: 230*500mm

Hammer Number: 40pcs

Size of the finished product: 10mm

Power of Main Motor: 22kw

Diameter of Dust remover: 800mm

Capacity: 500kg/h

Rotary dryer machine: reduce the moisture of sawdust

The moisture content of sawdust should be less than 15%. If the moisture content is too high, the processed wooden pallet will have a rough surface, low density, and unevenness.

Model: SL-D800

Weight: 1800kg

Thickness: 8mm

Diameter: 800mm(D)

Power: 3kw

Fan power: 5.5kw

Capacity: 500-600kg/h

Glue mixer: mix sawdust with glue

To increase the density of wood pallets, the sawdust needs to be mixed with glue, which is usually urea-formaldehyde resin glue. The purpose of this is to make the finished product stronger and have more load-bearing capacity.

Model: SL-900

Dimension: 1.5*1*1.4m

Diameter: 900mm

Weight: About 300kg

Power: 7.5kw

Glue: Urea-formaldehyde resin glue

Pallet press machine: produce wood pallets

The sawdust obtained by mixing glue is molded at high temperature and pressure. Combining different sizes and patterns of molds can produce different wooden pallets.

Model: SL-1000

Dimension: 1.9*1.3*4m

Pressure: 1000tons

Weight: 21000kg

Power: 15kw

Capacity: Produce one pallet need 4-5 minutes

Advantages of industrial pallet making plant

- High quality of finished pallets: compression-molded wood pallets are of high quality with smooth surfaces, high load-bearing capacity, good waterproof performance, and fumigation free. And there are no nails on the pallet to scratch the goods.

- Fully automated: the presswood pallet production line offers a fully automated production solution. Only one or two staff members are sufficient to handle the routine operations of the entire line.

- Wide range of applications: various shapes/sizes of pallets can be produced by simply changing the compression molding method.

- Cost saving: with stable operation and relatively low energy consumption, this production line is a good investment project.

Molds of hydraulic pallet press machine

The mold constitutes the primary component of the wooden pallet forming machine, comprising an upper convex part and a lower concave part.

During operation, when the mold is closed, raw materials undergo molding under high temperature and pressure. Upon opening the mold, the formed wood pallet can be extracted.

All types of pallets require specific molds that meet their unique requirements. We have both common sizes on the market and customization expertise. So when you want to invest in an automated presswood pallet production line, tell us the dimensions of the wooden pallets you want to produce and we will customize them for you.

Pallet making process finished product

As the whole presswood pallet production line is carried out under high temperature and pressure, the insect eggs and harmful substances have been killed. Therefore, during the export process, this kind of pallet does not need any fumigation treatment. And there is no need for additional processing or providing customs clearance documents.

Why invest in the production of wooden pallets?

Investing in a presswood pallet production line may be a profitable business for the following reasons:

- High demand: wooden pallets are used in a wide range of transportation and logistics applications, and are vital for transporting and storing goods in warehouses, distribution centers, and retail stores.

- Cost-effective: presswood pallets are relatively low cost compared to alternative materials such as plastic or metal. This cost advantage makes it the preferred choice for many businesses, especially those with large-scale transportation and storage needs.

- Recyclability and sustainability: wood pallets are often made from sustainably sourced wood and can be recycled or repaired when damaged.

- Diversified customer base: compressed wood pallets are in demand across a wide range of industries including manufacturing, retail, agriculture, and construction. This reduces dependence on a single industry and increases the diversity of market opportunities.

The machines we produce are of excellent quality and are exported to all over the world, including Brazil, Russia, Madagascar, Spain, and so on. We have more than 20 years of production experience in the pallet machinery industry. If you have an investment in this field, please contact us.

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

The rotary drum dryer machine is commonly used to evaporate…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives and a…

Automatic Saw Mill Machine For Wood Recycling Plant

The saw mill machine uses either a circular or band…

Wood Debarker Machine Timber Log Peeling Equipment

The wood debarker, equipped with high-strength alloy blades and advanced…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using the high-speed…

Wood Shaving Machine For Animal Bedding

The wood shaving machine is designed to transform wood of…

Wood Chipper Machine For Sawdust-making Plant

The wood chipper machine is designed to break down wood,…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down large pieces…

Feed Pellet Mill Machine For Animal Livestock

The feed pellet mill machine is a kind of equipment…

Hot Product

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment…

Horizontal Carbonization Furnace For Lump Charcoal Processing

Lump charcoal making machine is a kind of…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Wood Shaving Machine For Animal Bedding

The wood shaving machine is designed to process…

Pallet Block Machine For Wooden Packaging Production Plant

The standard sizes of wood blocks that can…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

Biomass charcoal making machine can extrude and shape…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down…