Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Continuous shisha charcoal machine | Hookah charcoal tablet machine

Rotary Shisha Charcoal Making Machine For Hookah Briquettes

Continuous shisha charcoal machine | Hookah charcoal tablet machine

Features at a Glance

The rotary shisha charcoal making machine is an automatic, double-press rotary tablet press designed for continuously pressing powdered materials into tablets. It is primarily used for producing water-smoked charcoal but can also serve in the pharmaceutical industry and in chemical, food, electronic, and other industrial applications.

The hookah charcoal tablets produced by this machine are well-shaped and visually appealing. They burn easily, are odorless, and have a long burn time. The tablets can be made in various shapes, including round and circular, with customizable molds available.

While operating, the rotary shisha charcoal making machine maintains a low noise level despite high pressure and features an overpressure stop function to prevent any damage to the machine.

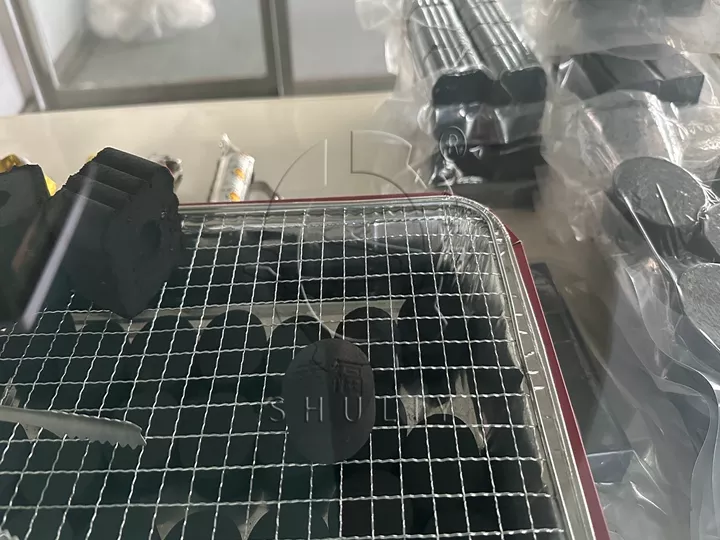

Raw material and finished product display

Our rotary shisha charcoal making machine is designed to press coconut shell charcoal powder, fruit wood charcoal powder, bamboo charcoal powder, and other types of charcoal powder that have been crushed by the hammer mill crusher. This allows us to create various shapes of hookah charcoal tablets.

In addition to pressing round tablets, we also have the capability to produce shaped tablets, special tablets, square tablets, and more. We can customize these according to your specific requirements. Typically, finished round pieces have a diameter of 33mm or 34mm, while finished square pieces usually measure 20*20*20mm and 25*25*25mm.

When the rotary shisha charcoal making machine is running, the machine noise is small, but the pressure is big, and it is equipped with an over-pressure stop function to make sure the machine is not damaged.

Main applications of the finished product

The rotary shisha charcoal making machine is primarily designed for producing hookah charcoal, a type of fuel block utilized in hookah pipes. This charcoal possesses distinct combustion characteristics and a unique flavor, making it essential for generating the smoke used in hookah smoking.

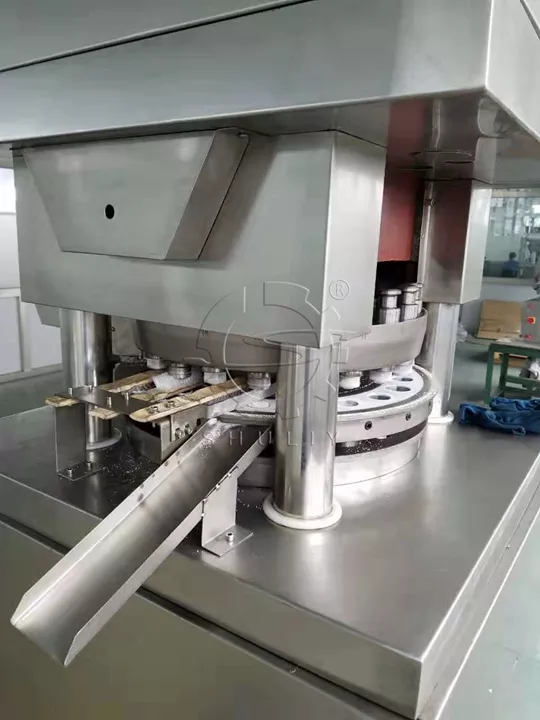

Rrotary hookah charcoal making machine main structure

The rotary shisha charcoal making machine primarily includes the frame, turntable, tablet press mold, power supply, control system, and discharge system.

This machine is primarily designed for producing tablets and similar products. The turntable and mold are the essential components of the rotary tablet press and serve as the main working area for creating charcoal briquettes.

Workflow of shisha charcoal making process

Making hookah charcoal often requires several processes: raw material crushing→mixing with binder→molding→drying→packaging. The corresponding machines are as follows.

Raw Material Preparation

To start, the raw materials for making hookah charcoal must be prepared. Typically, these include wood chips, bamboo chips, and other fibrous materials. These raw materials are then crushed into pieces smaller than 3mm using a hammer mill, which is essential for the molding process that follows.

Mixing

The raw materials will be combined with the right amount of binder to help maintain their shape and provide adequate bonding during the preparation of hookah charcoal. The binder can include options like vegetable gum or starch. This process takes place in a charcoal powder grinding machine.

Feeding and Molding

The rotary flaking charcoal machine compresses raw materials into small, shaped pieces that are pushed through holes in the rotating disk. This process is a form of extrusion and molding.

Drying

After molding, the water-smoked charcoal briquettes need to be dried in the batch charcoal drying machine (60-80℃, 8h/batch) to remove the moisture in them, increase the calorific value, and improve their stability.

Packaging and Storage

The dried hookah charcoal briquettes can be packaged through a hookah charcoal packing machine for transportation and sale. It can also be stored in a dry and ventilated place to ensure that its quality is not damaged.

Hookah charcoal press machine technical information

Different models of rotary shisha charcoal making machines can have varying technical specifications. When selecting the appropriate machine, it’s important to take into account these technical parameters along with other potential influencing factors based on your specific needs, production scale, and actual circumstances.

| Model | SL-ZP-17B |

| Punch quantity(sets) | 17 |

| Max. tablet pressure(kn) | 120 |

| Max. tablet diameter(mm) | 36 |

| Max. filling depth(mm) | 18-30 |

| Max. tablet thickness(mm) | 8-15 |

| Turret rotation speed(r/min) | 10-25 |

| Upper and lower punch diameters(mm) | 40 |

| Upper punch length(mm) | 175 |

| Lower punch length(mm) | 180 |

| Middle mold diameter(mm) | 52 |

| Max. output(pcs/h) | 25500 |

| Motor power(kw) | 7.5 |

| Overall size(mm) | 900x800x1640 |

| Machine weight(kg) | 1500 |

Main features of rotary hookah charcoal machine

- The peripheral cover is fully closed and made of stainless steel, which is in line with GMP requirements. The internal table top is specially treated to maintain luster and prevent cross-contamination.

- Equipped with transparent glass doors and windows that allow for clear observation of the pressing situation, and they can be opened for easy internal cleaning and maintenance.

- Features an overload protection device that automatically shuts down the machine when pressure exceeds safe limits, ensuring the equipment operates safely.

- PLC and touch screen control, are easy to operate, the user can intuitively display and set all kinds of parameters.

- The electrical control box is separated from the host to avoid dust contamination of electrical components, and the longer service life of the machine.

- The buyer can choose an optional forced feeding device, which can improve production efficiency.

Rotary shisha charcoal making machine sold to Morocco

Last month Morocco customer purchased a rotary shisha charcoal making machine from us. The customer’s demand was clear and directly sent us an inquiry for the hookah charcoal tablet press.

At first, we sent different types including charcoal briquette making machines to the customer, finally, the customer chose the rotary tablet press type.

Then we immediately provide PI to the customer and send more videos and pictures of the machine. The customer was satisfied with our charcoal briquette press machine and then paid the deposit.

Precautions for the use of charcoal briquette press machine

- People must repeatedly check the quality of the punching mold before use to make sure that there are no missing edges, cracks, deformations, and incomplete tightening and loosening.

- If there is a screaming or strange sound in use, stop the machine immediately to check and eliminate the fault, do not use it reluctantly.

- Rotary tablet press on the shield, safety cover, and other devices shall not be removed, be sure to install when in use.

- Use dry raw materials to avoid powder sticking to the punch surface.

- If the tablets jump or stagnate during the operation, the staff must not take them by hand to avoid the accident of hurting hands.

Our factory specializes in coal briquetting equipment with many years of experience. If you have any needs in this regard, please browse this website and feel free to contact us. We will provide you with more detailed information and recommend the most suitable machine for you.

Charcoal Briquette Machine For Fuel Production Line

The charcoal briquette machine is designed to compress coal or…

Stainless Steel Shisha Charcoal Making Machine For Hookah Briquette Tablets

The hookah coal tablets produced by stainless steel hydraulic shisha…

Charcoal Ball Press Machine For BBQ Industry

The charcoal ball press machines are designed to compress loose…

Honeycomb Coal Machine For Briquette Forming Production Line

The Honeycomb coal machine is to regard the well-processed coal…

Vertical Hoist Carbonization Furnace For Charcoal Making Plant

The hoist carbonization furnace is used for charring wood or…

Horizontal Carbonization Furnace For Lump Charcoal Processing

The horizontal carbonization furnace is a kind of equipment for…

Continuous Carbonization Furnace For Rice Husk Charcoal Making

Continuous charcoal carbonization furnace is an ideal equipment for dry…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

BBQ Charcoal Packing Machine in Briquette Production Line

The BBQ charcoal packing machine is a device specialized in…

Multifunctional Shisha Hookah Charcoal Packing Machine For Sale

In the charcoal processing industry, the hookah charcoal packing machine…

Hot Product

Stainless Steel Shisha Charcoal Making Machine For Hookah Briquette Tablets

The shisha charcoal making machine is also a…

Briquette Charcoal Dryer For Honeycomb Shisha Coal Production

Briquette charcoal dryer refers to the evaporation of…

Automatic Saw Mill Machine For Wood Recycling Plant

The saw mill machine cuts larger logs into…

Pallet Block Machine For Wooden Packaging Production Plant

The standard sizes of wood blocks that can…

Feed Pellet Mill Machine For Animal Livestock

Feed pellet mill is used for making animal…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Automatic Wood Pallet Press Machine For Sale

Wood pallet press machine mainly process compressed wooden…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…