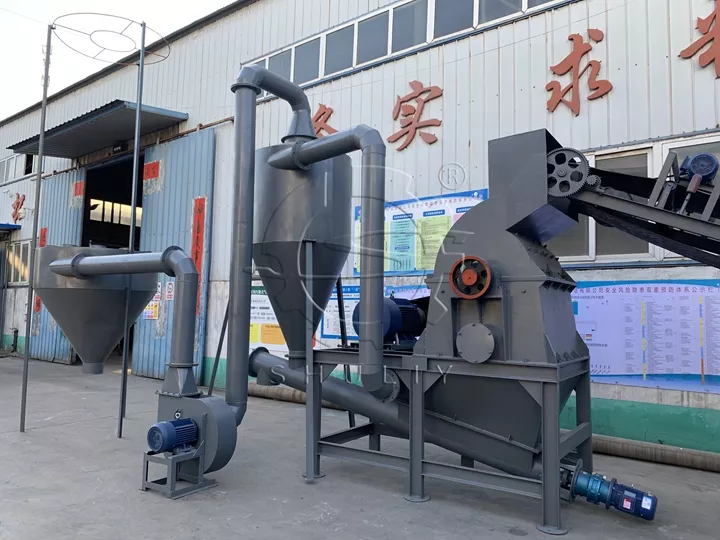

Large Hammer Mill Crusher in Sawdust-making Plant

Hammer mill shredder | Wood hammer crushing machine

Large Hammer Mill Crusher in Sawdust-making Plant

Hammer mill shredder | Wood hammer crushing machine

Features at a Glance

The wood hammer mill crusher operates by using the high-speed rotation of hammers within the machine to break down large wood chips into 3-5 mm sawdust, which is essential for producing wood pellets and sawdust.

This machine is capable of crushing hard, soft, and mildly corrosive materials, resulting in uniformly sized particles with appropriate moisture levels. It finds extensive application in wood processing, biomass pellet production, animal feed processing, wood board manufacturing, and various other industries.

In comparison to other types of crushers, the wood hammer crusher offers several advantages, including a large crushing ratio, high production capacity, consistent particle size, and low energy consumption. Depending on the driving method, hammer crushers can be categorized into electric, diesel, PTO-driven, and more. Additionally, a wheeled base can be included for enhanced mobility.

Wide application of hammer crushing machine

The hammer mill crusher is not designed for processing raw materials that are sticky, greasy, or have excessive moisture content. Additionally, the raw materials should be free of metal or other hard foreign objects.

Besides crushing typical materials like wood, bark, wood chips, shavings, and boards, the hammer crusher is also capable of handling crop stalks, corn, nut shells, peanut shells, and more.

Furthermore, if the diameter or thickness of the wood exceeds 4cm, it is generally recommended to use a wood chipper first to reduce the thick wood into smaller chips. (Related Post: Wood Chipper Machine For Sawdust-making Plant>>) This approach not only enhances output but also minimizes wear and tear on the machine.

Hammer mill crusher finished product

The finished product after processing by the wood hammer mill is usually crushed wood particles or fibrous materials, and its specific form and use depend on the type of raw materials and processing requirements. The following are some possible finished products:

- Wood pellets: these pellets are usually used for biomass energy production, such as wood pellet fuel, for heating, power generation, and so on.

- Biomass Pellets: the wood hammer mill can also process straw, bamboo, corn stalks, etc., into biomass pellets. These pellets can be used as animal feed, organic fertilizer, etc.

- Wood pulp: a wood hammer chip mill can also process wood into wood pulp for the production of paper, fiberboard, particle board, and other wood products.

Hammer mill crusher main structure

Externally, the main part of the machine includes the inlet, crushing chamber, and discharging port.

- Inlet: the raw material wood is put into the machine for crushing.

- Crushing chamber: it is the main area of wood crushing, and there are several rotating hammer blades or hammers inside.

- Discharge port: the crushed wood chips are discharged from the machine through the discharge port.

Pad plate: in the high-intensity operation of the hammer blade working process, to protect the machine’s back shell, we added a pad plate inside, which makes the machine not easy to damage, more wear-resistant, and longer life.

Sieves: its primary role is to regulate the output size, and by adjusting the screen with various apertures, different sizes of final products can be achieved.

Cyclone dust collector: after crushing the material can subsequently be equipped with a dust collector, of the material by the fan blowing the dust collector, coupled with the bag, and the role is to collect dust to prevent pollution.

Advantages of wood hammer mill crusher

- The output of a large hammer mill crusher can reach three to four times of a small wood crusher.

- It can transform raw materials of various or uneven sizes into consistent wood particles.

- Various screen sieve can be chosen to meet different raw material grinding requirements.

- The hammer mill crusher machine is thoughtfully designed with safety in mind and includes protective safety features.

- The hammers are built for extended use, which makes them prone to wear. To enhance durability against impact, the corners of the hammer head are reinforced with a wear-resistant alloy.

How the hammer wood crusher works?

When the hammer crusher operates, the motor turns the rotary shaft, causing the hammers attached to it to spin rapidly. Wooden materials are introduced into the crushing chamber through the inlet and are swiftly broken down by the force of the high-speed rotating hammers.

The resulting crushed material is then screened through a mesh inside the machine. The size of the screen’s openings can be adjusted to control the final product’s particle size. Smaller particles can pass through the mesh, while larger ones remain inside the machine for further crushing.

Technical data of hammer wood shredder

| Model | SL-60 | SL-70 | SL-80 | SL-90 | SL-1000 | SL-1300 |

| Power(kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Hammers(pcs) | 30 | 40 | 50 | 50 | 105 | 105 |

| Fan(kw) | 7.5 | 7.5 | 11 | 22 | ||

| Dust remover(pcs) | 5 | 5 | 5 | 5 | 14 | 14 |

| Cyclone diameter(M) | 1 | 1 | 1 | 1 | 1 | 1 |

| Capacity (T/h) | 0.8-1 | 1-1.5 | 1.5-2 | 2-3 | 3-4 | 4-5 |

Our straightforward design, compact size, user-friendly operation, and minimal maintenance make this machine the top choice for homes, farms, or small pellet mills. We can tailor the size to fit your specific needs. Don’t hesitate to reach out for the most current pricing on the wood hammer mill crusher machine!

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

The rotary drum dryer machine is commonly used to evaporate…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives and a…

Automatic Saw Mill Machine For Wood Recycling Plant

The saw mill machine uses either a circular or band…

Wood Debarker Machine Timber Log Peeling Equipment

The wood debarker, equipped with high-strength alloy blades and advanced…

Wood Shaving Machine For Animal Bedding

The wood shaving machine is designed to transform wood of…

Wood Chipper Machine For Sawdust-making Plant

The wood chipper machine is designed to break down wood,…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down large pieces…

Feed Pellet Mill Machine For Animal Livestock

The feed pellet mill machine is a kind of equipment…

Automatic Wood Pallet Press Machine For Sale

The wood pallet press machine is our featured product, mainly…

Hot Product

Horizontal Carbonization Furnace For Lump Charcoal Processing

Lump charcoal making machine is a kind of…

Wood Shaving Machine For Animal Bedding

The wood shaving machine is designed to process…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…

Briquette Charcoal Dryer For Honeycomb Shisha Coal Production

Briquette charcoal dryer refers to the evaporation of…

Wood Debarker Machine Timber Log Peeling Equipment

Equipped with high-strength alloy blades and advanced rotary…

Charcoal Briquette Machine For Fuel Production Line

Charcoal briquette machine, also known as a briquette…

Feed Pellet Mill Machine For Animal Livestock

Feed pellet mill is used for making animal…

Charcoal Ball Press Machine For BBQ Industry

Charcoal ball press machine is efficient and convenient…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using…