Sawdust Briquettes Production Line Pini Kay Making Machines

Sawdust Briquettes Production Line Pini Kay Making Machines

The sawdust briquettes production line processes raw materials such as sawdust and rice husk into biomass fuel with a certain density and shape, also called pini kay heat logs, through a series of processes such as high temperature and pressure.

These wooden sawdust briquettes are usually used for domestic, commercial, and industrial purposes, such as barbecue, heating, stove fuel, and so on. This sawdust briquettes production line is suitable for wood charcoal briquette manufacturers of different sizes. The output ranges from 500kg/h to 2t/h.

Raw materials of sawdust briquettes production line

There are many raw materials used to process pini kay briquettes. Among them, sawdust and rice husk are the most common raw materials. In addition, wood scraps from furniture factories, wood chips, wood shavings, and wood shavings can also be used to process high-quality wood sawdust briquettes.

Various agricultural stalks can also be used to process sawdust briquettes, such as cotton stalks, sorghum stalks, rice stalks, corn stalks, corn cobs, rice husks, peanut shells, palm shells, tree branches, coconut shells, coffee grounds, bagasse, and so on.

The common point of these raw materials is that they all contain a certain amount of lignin. Lignin is an important raw material for coal molding. Under high pressure and high-temperature conditions, lignin can be re-molded.

Biomass fuel making line finished product

Wood sawdust briquettes can be burned directly as fuel, and compared with natural wood, they have higher density and calorific value and burn longer. What’s more, using wood residues and agricultural waste to produce pellets helps reduce the felling of trees.

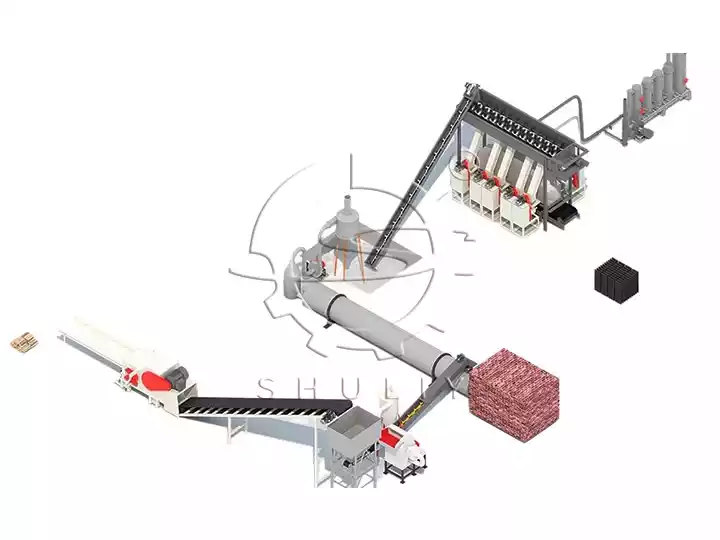

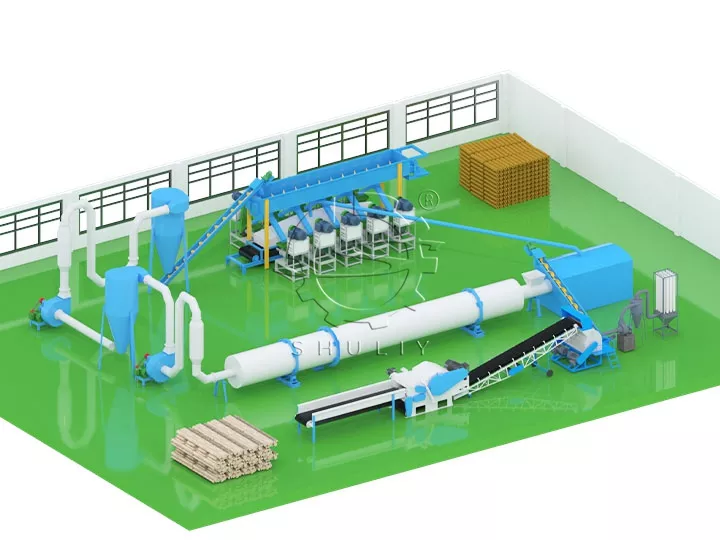

Sawdust briquetting processing plant workflow

A complete sawdust briquettes production line should include the following range of wood processing equipment: wood chipping machine → hammer mill crusher→ screw conveyor → rotary dryer machine→ screw conveyor → screw separator → pini kay briquettes machine → heat shrink film packaging machine.

Among them, the heat shrink film packaging machine is optional equipment, customers can choose whether to buy according to their own needs. In addition, if the raw material to be processed is dry itself and the moisture is below 12%, then there is no need to buy drying equipment.

Process of making wood biomass briquettes

As for the model of each machine in the pini kay briquette production line, we usually customize it according to the customer’s investment budget and processing requirements. In general, we will provide customers with a detailed sawdust briquette production plan. The following are some basic equipment for pini kay briquette processing.

Hammer mill crusher: crush wood logs into sawdust

In the sawdust briquettes production line, the hammer mill crushes and processes the larger-sized raw materials to meet the wood briquette extruder feed size of 3-5mm.

Screw conveyor: transfer of raw materials

This equipment is responsible for transferring the crushed material to the rotary drying machine, as well as transferring the dried material to the screw separator.

Rotary dryer machine: reduce the moisture of sawdust

Reduce the moisture of raw material to below 12%. If materials are too wet, it will cause the surface of the finished product to be cracked and bent, as well as clog the outlet, and the machine will make a popping sound, which is unsafe.

Screw separator: uniform feed materials into sawdust briquettes machine

This device evenly distributes the raw materials to the different sawdust briquette machines’ inlets, the number of outlets as well as the size of the bins can be customized.

Pini kay briquettes machine: shaped into wood sticks

The sawdust briquettes production line is equipped with several sets of this machine. Distributed on both sides of the powder machine, usually 3 or 5 on one side. For more information about this machine, please click on the article: Sawdust briquette machine for biomass charcoal processing line.

Consumable parts

The front section of the propeller has the greatest friction with the material and is most susceptible to wear. Our screw propeller shaft is made of Cr40 steel, which achieves a good balance between the toughness and wear resistance of the propeller shaft.

The molding sleeves are available in square and hexagonal shapes. A large number of tests and production practices have shown that the wood chip pellets produced by the 4.8-5cm forming sleeves have the best quality and are therefore the most popular.

Heat shrink film packaging machine: packing the wood sticks

After the finished product is packaged, it can achieve the effect of moisture-proof, and it is easy to carry. If it is not packaged, the product can also be directly carbonized.

Advantages of Shuliy pini kay briquette production line

Our biomass sawdust briquettes production line has become the first choice of global customers for its efficient production capacity, customized design, comprehensive services, and significant economic benefits. The successful case of Ghanaian customers further proves the reliability and excellent performance of our equipment.

- Mass production: our factory has improved production technology and saved labor, so the price is relatively affordable, the waiting time for customers is greatly shortened, and the machine processing and delivery are completed at the fastest speed.

- Machine customization and international hot sales: our equipment has been exported to many countries including the United States, Germany, France, the United Kingdom, the United Arab Emirates, Saudi Arabia, Egypt, India, Pakistan, Morocco, Tunisia, Canada, Australia and South Africa.

- Design and solution customization and installation service: the engineering team will personally go to the customer’s site to install and debug the equipment to ensure the smooth commissioning of the production line. With our full support, the Ghanaian customer started the production line quickly and achieved the expected results.

- Economic cost-effectiveness: by using biomass waste for production, customers not only reduce raw material costs but also increase product-added value.

We accept your customization

The above is our company’s regular configuration program for reference only. We can customize it according to the customer’s budget, output, and finished product size requirements.

To get the sawdust briquettes that meet the needs of the majority of users, we are equipped with the appropriate model of each piece of equipment in the entire production line, saving customers the trouble of choosing the model of the machine.

In addition, in the sawdust briquettes production line, we give free accessories such as heating rings, heating spirals, molding cylinders, and so on. If you want to know more details about the machine, please feel free to contact us.

Sawdust Briquette Machine For Biomass Charcoal Processing Line

The sawdust briquette machine is designed to compress waste materials…

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

The rotary drum dryer machine is commonly used to evaporate…

Wood Crusher Machine For Making Sawdust

The wood crusher machine features high-speed rotating knives and a…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using the high-speed…

Wood Chipper Machine For Sawdust-making Plant

The wood chipper machine is designed to break down wood,…

Comprehensive Crusher Large Capacity Wood Shredder Machine

The comprehensive crusher is designed to break down large pieces…

Pallet Block Machine For Wooden Packaging Production Plant

The wood pallet block machine is an efficient solution for…

Presswood Pallet Production Line For Wood Recycling Plant

The presswood pallet production line is dedicated to making molded…

Automatic Compressed Wood Pallet Blocks Production Line For Sale

The wood pallet blocks production line uses waste wood chips,…

Sawdust Charcoal Production Line For Biomass Processing Plant

The sawdust charcoal production line takes wood, wood chips, or…

Hot Product

Rotary Drum Dryer Machine For Sawdust Powder Drying Plant

Rotary drum dryer machine is a common industrial…

Feed Pellet Mill Machine For Animal Livestock

Feed pellet mill is used for making animal…

Charcoal briquette mesh belt dryer for continuous drying plant

Charcoal briquette mesh belt dryer is a continuous…

Sawdust Briquette Machine For Biomass Charcoal Processing Line

Biomass charcoal making machine can extrude and shape…

Charcoal Briquette Machine For Fuel Production Line

Charcoal briquette machine, also known as a briquette…

Large Hammer Mill Crusher in Sawdust-making Plant

The wood hammer mill crusher operates by using…

Charcoal Grinder Machine For Briquette Molding Plant

Charcoal grinder machine has the functions of crushing,…

Horizontal Carbonization Furnace For Lump Charcoal Processing

Lump charcoal making machine is a kind of…

Automatic Heat Shrink Film Charcoal Briquette Packing Machine

Shrink charcoal briquette packing machines are well suited…