Frequently Asked Questions and Precautions on the Use of Wood Briquetting Machine

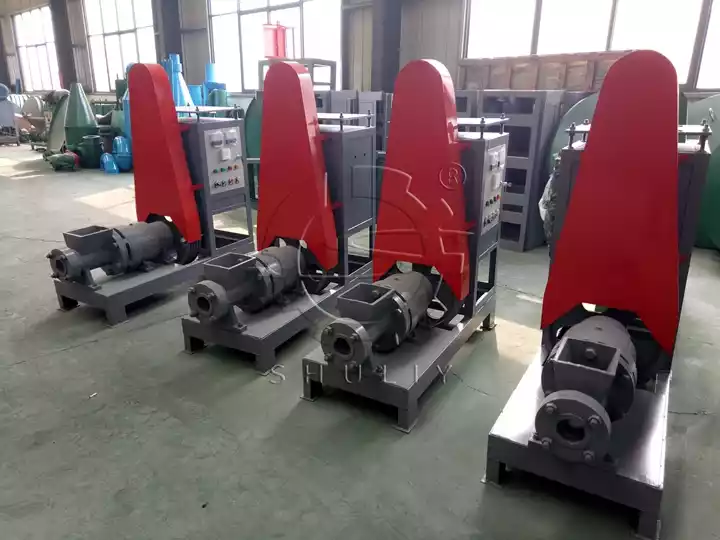

The wood briquetting machine is a device that can extrude the crushed wood materials into high-temperature shapes. Most of the extruded finished products will be processed into charcoal rods through a carbonization furnace and used as fuel. The rod-making machine has stable working performance at the set temperature and has the advantages of reasonable structure, simple operation, and maintenance.

Raw Materials Processed by Wood Briquetting Machine

The raw materials of the sawdust briquette-making machine are very wide, such as rural crop straw, cotton straw, sesame stalk, corn straw, and corn cob. Scrap from furniture factories, bamboo factories, chopstick factories, etc. There are also pruned branches from orchards, gardens, etc. These raw materials need to be crushed first by a hammer wood crusher.

Sawdust Briquette Making Machine Related FAQs

- Is the length of the wooden stick adjustable?

Yes, the position of the baffle can be controlled, and the length of the baffle is 10-15cm. - What is the output of the machine?

The output of this type of wood briquetting machine on the market is 250kg/h. If the customer insists on a large output, two units are recommended. - Why can’t the raw materials be too wet?

The raw materials will stick to the spiral, cannot be squeezed out, cannot be shaped, and will cause greater wear and tear. - What are the molds for the rod-making machine?

Hexagonal ones have holes, square ones have holes, and those without holes cannot be made. - What is the density of the sawdust briquette-making machine?

It is very related to the raw materials. The harder the raw materials, the greater the density, 1-1.3t/m³.

Precautions When Using Briquette Press Machine

- During production, pay attention to whether the motor current and voltage are normal to prevent damage to the motor.

- It is strictly forbidden to stand in front of the discharge port when the machine is started.

- Electrical circuits should be kept dry and clean, and the power supply should be cut off when shutting down.

- It is strictly forbidden to allow stones and iron filings to enter the hopper. If any abnormality is found, stop the wood briquetting machine immediately.

- All lubricated parts should be lubricated once every 2 months.

- If the fuselage is not well grounded, it is strictly prohibited to turn it on!

For more information about the wood briquetting machine, please visit this website and feel free to contact us, we will reply to you in the fastest time.