Parça Kömür İşleme İçin Yatay Karbonizasyon Fırını

Yatay kömür yapma makinesi | Hava akımı ahşap karbonizasyon fırını

Parça Kömür İşleme İçin Yatay Karbonizasyon Fırını

Yatay kömür yapma makinesi | Hava akımı ahşap karbonizasyon fırını

Bir Bakışta Özellikler

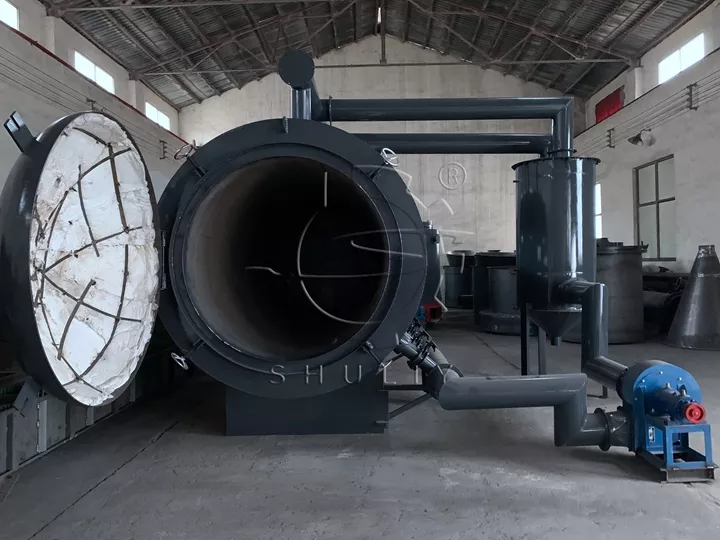

Yatay karbonizasyon fırını, tıpkı dikey karbonizasyon fırını gibi odun ve diğer hammaddeleri kömürleştirmek için kullanılan bir tür ekipmandır. Yatay kömür fırını olarak adlandırılmasının nedeni, kömür haznesinin düzeninin makine yüksekliğini azaltmak amacıyla yatay olarak yerleştirilmesidir. Bu nedenle hammaddelerin yüklenmesi daha uygundur.

Yatay karbonizasyon fırınındaki hammaddeler, yüksek sıcaklıkta ve oksijensiz ortamda piroliz yoluyla kömüre dönüştürülür. Her fırının çıkışı 2,5-3 ton/12-14 saate kadar çıkabilir.

Diğer hava akışlı karbonizasyon fırınlarında olduğu gibi duman geri dönüşüm sistemi de içerir. Karbonizasyon işleminde oluşan duman, arıtıcıya girer ve daha sonra fırının ısıtılması için ateşlenir. Ayrıca yedek gaz, talaş kurutucusu, kazan vb. için ısı kaynağı olarak kullanılabilir.

Dikey tip kömürleştirme fırınları hakkında ayrıntılı bilgiyi Odun Kömürü Yapma Tesisi için Dikey Vinçli Karbonizasyon Fırını tıklayarak öğrenebilirsiniz.

Parça kömür yapma makinesinin kullanımı nedir?

Parça kömür yapma makinesi odun kütüklerini, dallarını, köklerini, bambu, biyokütle briketlerini, mısır koçanlarını, hindistancevizi kabuklarını, fındık kabuklarını, yer fıstığı kabuklarını, ceviz kabuklarını, biçilmiş keresteyi, mısır saplarını, küspeyi, pirinç kabuğunu, bambu cipslerini, sorgum saplarını işleyebilir , diğer birçok malzeme.

Bitmiş ürünün daha fazla işlenmesi: Biyokütle briketleri hariç, diğer malzemelerin kömür kırıcı kullanılarak ince öğütülmesi gerekir. Bundan sonra, yalnızca bir odun kömürü ekstrüzyon makinesi, nargile kömürü makinesi, odun kömürü topu pres makinesi ve diğer ekipmanlar tarafından preslenip şekillendirilebilir.

Yatay karbonizasyon fırınının bitmiş ürünü

Yatay kömür fırınlarının nihai ürünleri genellikle briketler ve çeşitli düzensiz şekillerde karbonize edilmiş malzemelerden oluşur. Odun biyokütlesini hammadde olarak kullanan yatay karbonizasyon fırınları, yüksek kaliteli odun biyokütlesi kömürü hazırlayabilir. Bu tür kömürün rengi koyudur, dokusu serttir ve yakıldığında genellikle ısıtma, pişirme ve endüstriyel yanma için kullanılan sabit ısı enerjisi açığa çıkarır.

Sertağaç karbonizasyon fırınının organizasyonu

Yatay karbonizasyon fırını esas olarak bir karbonizasyon odası, ısıtma ekipmanı, raf, baca gazı arıtma sistemi, kontrol sistemi, cüruf boşaltma cihazı, besleme portu ve boşaltma portundan oluşur. Ayrıca dış soba ile iç soba arasında yalıtkan bir pamuklu sandviç tabakası bulunmaktadır.

Yatay odun kömürü makinesinin iş akışı

Yatay karbonizasyon fırını, hammaddelerdeki nemi ve uçucu maddeleri serbest bırakmak ve bir dizi kimyasal reaksiyon yoluyla stabil kömür ürünleri oluşturmak için karbonizasyon odasındaki sıcaklığı, zamanı ve ortam atmosferini kontrol eder.

- Hammaddeleri yatay karbonizasyon fırınının kömürleme odasına koyun.

- Isıtma ekipmanını çalıştırın (yakmalı fırın, gazlı fırın veya elektrikli ısıtıcı gibi).

- Yüksek sıcaklık ve oksijensiz ortamda hammadde karbonizasyon reaksiyonunu gerçekleştirmeye başlar.

- Kömürleşme işlemi sırasında büyük miktarda duman ve uçucu madde üretilecektir. Yatay kömür fırını, üretilen egzoz gazını toplayan ve işleyen bir gaz giderme sistemine sahiptir.

- Odun kömürü yapma makinesi, kömürleştirme işlemi sırasında sıcaklığı, basıncı ve duman emisyonlarını izlemek ve düzenlemek için otomatik bir kontrol sistemi ile donatılmıştır.

- Yatay bir karbonizasyon fırını, kül ve katranı toplayan bir cüruf boşaltma cihazı ile donatılmıştır.

- Karbonizasyon işlemini tamamladıktan sonra bitmiş kömürü çıkarın.

Kömür kömürleme fırını hakkında teknik bilgi

| Modeli | Fırın başına kapasite | Boyut | Ağırlık |

| 1300 | 900-1200kg/12-14saat | 3*1.7*2.2M | 2500kg |

| 1500 | 1500-2000kg/12-14saat | 4,5*1,9*2,3M | 4000kg |

| 1900 | 2500-3000kg/12-14saat | 5*2.3*2.5M | 5500kg |

Yatay kömürleme fırınının özellikleri

- Ana makinenin büyük hacmi, yüksek kömürleşme oranı, güçlü üretim kapasitesi, saatte 3-10 ton kömürleşme.

- Birçok hammadde türüne uygulanabilir: Parça kömür yapma makineleri, ahşap, bambu, meyve kabukları, tarımsal atıklar vb. dahil olmak üzere birçok türde hammaddeyle başa çıkabilir.

- Düşük maliyet ve yüksek pratiklik, ilk girişimcilerin yatırım gereksinimlerini karşılar.

- Topak kömür fırını makinesi, iyi ısı koruma performansına sahip, sağlam ve dayanıklı, deforme olmayan, yüksek sıcaklığa dayanıklı özel paslanmaz çelikten yapılmıştır.

Yatay kütük karbonizasyon fırınının sevkiyatı

Shuliy'nin yığın karbonizasyon fırını, Ekvador, Tunus, Endonezya, Kenya, İtalya, Lübnan, Uganda ve benzeri birçok ülkeye satılmıştır. İşte makinenin paketleme ve nakliye resmi:

Fabrikamız ayrıca sürekli karbonizasyon fırınları da üretmektedir. Makinelerimizle ilgileniyorsanız, lütfen bizimle iletişime geçmekten çekinmeyin, size daha ayrıntılı bilgi ve makine fiyat teklifleri sunacağız.

Kömür Kömürü Makinesi Yakıt Üretim Hattı İçin

Kömür briquet makinesi kömürü veya … sıkıştırmak için tasarlanmıştır

Paslanmaz Çelik Şişa Kömürü Yapım Makinesi Hookah Kömürü Tabletleri İçin

Paslanmaz çelik hidrolik şişe nargile kömürü tabletleri ile üretilir…

Döner Şişa Kömürü Yapma Makinesi Hookah Kömürü İçin

Rotasyonel şişe nargile kömürü yapma makinesi otomatik, çift baskılı…

Kömür Topu Pres Makinesi Barbekü Endüstrisi İçin

Kömür topu pres makineleri gevşek kömürü sıkıştırmak üzere tasarlanmıştır…

Petek Kömür Makinesi Briket Oluşturma Üretim Hattı İçin

Balık ağacı kömür makinesi iyi işlenmiş kömürü dikkate alır…

Dikey Kızaklı Kızıltaş Fırını Kömür Üretim Tesisi İçin

Vinçli karbonizasyon fırını ağaçları kömürleştirmek için kullanılır…

Pirincin Külünden Kömür Yapımı İçin Sürekli Kızıltaş Fırını

Sürekli kömür karbonizasyon fırını kuru için ideal bir ekipmandır…

Odun Tozu Kömür Makinesi Biyokütle Kömürü İşleme Hattı İçin

Talaş briket makinesi, atık malzemeleri sıkıştırmak için tasarlanmıştır…

Barbekü Kömürü Paketleme Makinesi Kömür Presleme Hattında

Barbekü kömürü paketleme makinesi,… konusunda uzmanlaşmış bir cihazdır…

Çok Fonksiyonlu Şişa Nargile Kömürü Paketleme Makinesi Satışta

Kömür işleme endüstrisinde, nargile kömürü paketleme makinesi…

Sıcak Ürün

Dikey Kızaklı Kızıltaş Fırını Kömür Üretim Tesisi İçin

Odun kömürü yapma fırını kömürleme için kullanılır…

Döner Şişa Kömürü Yapma Makinesi Hookah Kömürü İçin

Döner nargile kömür yapma makinesi çift baskı mekanizmasına sahiptir…

Barbekü Kömürü Paketleme Makinesi Kömür Presleme Hattında

Barbekü kömürü paketleme makinesi, özel bir…

Ahşap Ambalaj Üretim Tesisi İçin Palet Blok Makinesi

Parçalanabilecek odun bloklarının standart boyutları şunlardır…

Otomatik Isı Daraltıcı Film Kömür Briquette Paketleme Makinesi

Isıl büzüşmeli kömür briket paketleme makineleri iyi uygundur…

Kömür Öğütme Makinesi Briquet Şekillendirme Tesisi İçin

Kömür öğütme makinesi kırma, … işlevlerine sahiptir

Otomatik Ahşap Palet Pres Makinesi Satılık

Ahşap palet pres makinesi esas olarak sıkıştırılmış ahşapları işler…

Odun Tozu Kömür Makinesi Biyokütle Kömürü İşleme Hattı İçin

Biyokütle kömür yapma makinesi ekstrüzyon yapabilir ve şekillendirebilir…

Kömür kömür örgü bandı kurutucu sürekli kurutma tesisi için

Kömür briket örgü bantlı kurutucu sürekli bir…