Holzkohlebrikettmaschine für die Kraftstoffproduktionslinie

Kohlepressmaschine | Extruder für Holzkohlebriketts

Holzkohlebrikettmaschine für die Kraftstoffproduktionslinie

Kohlepressmaschine | Extruder für Holzkohlebriketts

Funktionen auf einen Blick

Die Holzkohlebrikettmaschine dient zum Pressen von Kohle oder Holzkohlepulver in verschiedene Brikettformen. Zu den Rohstoffen können kleine Reste gebrochener Kohle gehören, die bei der Lagerung, dem Transport oder nach der Verwendung in einem Ofen anfallen.

Der Einsatz dieser Holzkohlemaschine ermöglicht das vollständige Recycling und die Nutzung von Kohlepulverressourcen, was zur Senkung der Brennstoffkosten beiträgt, den Heizwert der Kohle erhöht und erhebliche wirtschaftliche Vorteile bietet.

Bevor Briketts entstehen, muss das Kohlepulver gemischt und leicht angefeuchtet werden. Die resultierenden Holzkohlebriketts zeichnen sich durch eine hohe Dichte aus und erzeugen bei der Verarbeitung weder Rauch noch Geruch. Diese Briketts finden umfangreiche Anwendung bei Großgrills, Kesselheizungen, Energieerzeugung und vielem mehr.

Mit einer Holzkohlebrikettmaschine kann man die Ausnutzungsrate der Kohle erhöhen und die Emission und Emission von Kohlenstaub reduzieren. Darüber hinaus bietet es die Möglichkeit, losen Kohlenstaub oder Abfallkohle bequem und wirtschaftlich in kompakte Kohlestäbe umzuwandeln, die leicht zu lagern, zu transportieren und zu verwenden sind.

Die Kohlepressmaschine von Shuliy ist leistungsstark und kann verschiedene Formen von Kohlestangen herstellen. Wir passen die Form der Maschine an die Bedürfnisse des Kunden an.

Wofür können Holzkohlebriketts verwendet werden?

Die Brikettiermaschine kann pulverisiertes Holzkohlepulver in verschiedene Formen von Stangenblöcken umwandeln. Es eignet sich zur Bildung vieler Arten von Rohstoffen wie Kohlenstoffpulver, Kohlepulver, Kohleschaum, Kohlegang, Kokskohle, Braunkohle, Anthrazit, Eisenpulver und Aluminiumpulver.

- Erhitzen und Kochen: Holzkohlebriketts können als fester Brennstoff zum Heizen und Kochen verwendet werden. Die Leute verwenden es in Öfen, Kaminen und Kaminen. Kohlestangen werden auch als Brennstoff für Grills verwendet. Es kann auch drinnen oder draußen für Wärme sorgen.

- Industrielle Anwendungen: Auch in der Industrie werden Kohlebriketts häufig eingesetzt. Sie können als Brennstoff für Stahlwerke, Kraftwerke, Zementfabriken und andere energieintensive Anlagen zur Stromerzeugung, Heizung oder für andere Produktionsprozesse verwendet werden.

- Umweltverbesserung: In einigen Gebieten kann der Einsatz von Kohlestäben auch die Umweltbedingungen verbessern. Beispielsweise kann die Umwandlung von losem Kohlenstaub oder Abfallkohle in Kohlestäbe die Staub- und Partikelemissionen reduzieren und negative Auswirkungen auf die Luftqualität minimieren.

Struktur der Holzkohlebrikettpresse

Der Aufbau einer Holzkohlebrikettmaschine ist relativ einfach und leicht zu bedienen und zu warten. Er besteht hauptsächlich aus einem Motor, einem elektronischen Steuerschrank, einem Reduzierstück, einem Lager, einem Zufuhreinlass, einer Schraube, einer Form, einem Schneider usw.

Wie funktioniert der Kohlebrikettierextruder?

Der Arbeitsprinzip ist wie folgt:

- Der Motor treibt das Untersetzungsgetriebe an, das wiederum die Drehung der Hauptwelle antreibt.

- Durch die Drehung der Hauptwelle wird die Kraft auf die Schnecke übertragen, die die Extrusion des Materials vorantreibt.

- Die Schnecke fördert das Kohlenstoffpulver/Kohlepulver von der Zufuhröffnung in das Innere der Form.

- Die Form übernimmt die Rolle des Formens, indem sie das Material zu Kohlestäben mit einer bestimmten Form und Festigkeit komprimiert.

Parameter des Holzkohlebrikett-Extruders

Abhängig von den unterschiedlichen Anforderungen des Benutzers an Fertigprodukte usw. können wir eine Vielzahl von Maschinenmodellen zur Auswahl herstellen. Im Folgenden finden Sie drei unserer meistverkauften Modelle.

| Modell | Produktionskapazität | Formspezifikationen (Durchmesser) | Spindelgeschwindigkeit | Spiralblattnummer | Motor |

| MBJ140 | 1-2 Tonnen/h | 20-40mm | 46-60/Std | 4 | Y160L-415KW |

| MBJ180 | 2-3 Tonnen/h | 20-60mm | 39-60/Std | 4 | Y180L-422KW |

| MBJ210 | 3-4 Tonnen/h | 20-80mm | 35-60/Std | 4 | Y200L-430KW |

Unterstützende Ausrüstung der Kohlepressmaschine

Bevor das Rohmaterial in die Holzkohlebrikettmaschine gelangt, ist es notwendig, das Rohmaterial mit einer Radmühle zu mischen, wobei dem Rohmaterial Bindemittel und Wasser zugesetzt werden.

Wheel mill machine

Die Holzkohlebrikettmaschine hat lediglich die Funktion, Kohlestangen zu extrudieren. Das von der Maschine extrudierte Endprodukt ist ein durchgehender langer Stab. Daher muss es mit einem Schneidwerk und einem Förderband ausgestattet sein, um konsistente und standardisierte Kohlestäbe herzustellen.

Schneidemesser

Pneumatischer Schneider: Es wird am Ausgang der Holzkohlenpressmaschine installiert. Die Länge der Stangen kann durch das Einstellen des Infrarotgeräts am Schneider bestimmt werden. Der Schneider arbeitet, wenn der Infrarotsensor die Kohlerohre erfasst.

Rollmesser: In der Regel verwenden die Leute den Schneider und das Rollmesser zusammen. Dieses wird auf dem Förderband installiert. Die beiden Messer zusammen erzeugen quadratische Holzkohle.

Durchflussmesser-Schneider: Der Schneider ist ebenfalls am Ausgang der Kohlestabmaschine installiert. Dieser Schneider ist genauer beim Abmessen und besser im Schneiden. Er kann verwendet werden, wenn der Benutzer eine hohe Nachfrage nach dem Erscheinungsbild der Kohlen hat.

Förderband

Das Förderband hilft beim Transport der fertigen Briketts, und die Installation des Schneiders am Band kann dem Kunden helfen, Briketts oder Stücke in verschiedenen Längen und Quadraten herzustellen. Gleichzeitig trägt das Förderband dazu bei, dass sich die Kohlen nicht verformen.

Holzkohle-Trockner

Darüber hinaus muss das fertige Produkt nach der Herstellung durch einen Trockner geführt werden, bevor es verpackt werden kann. Um zu verhindern, dass das fertige Produkt umkippt, wählen wir normalerweise einen Batch-Holzkohle-Trockner.

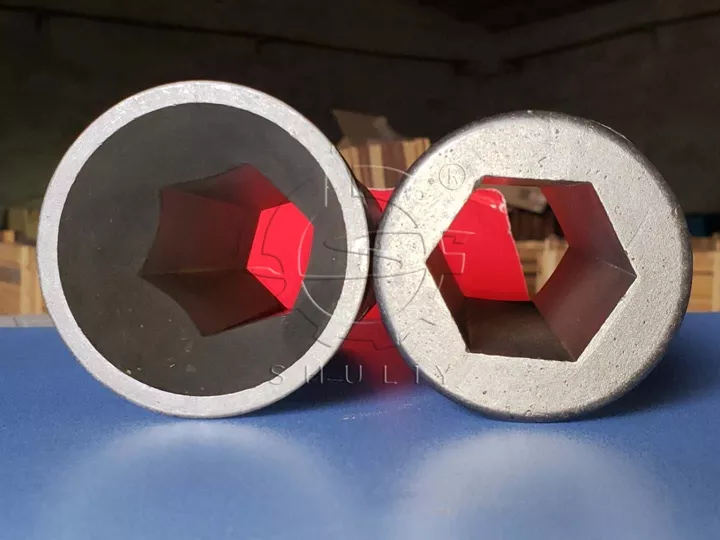

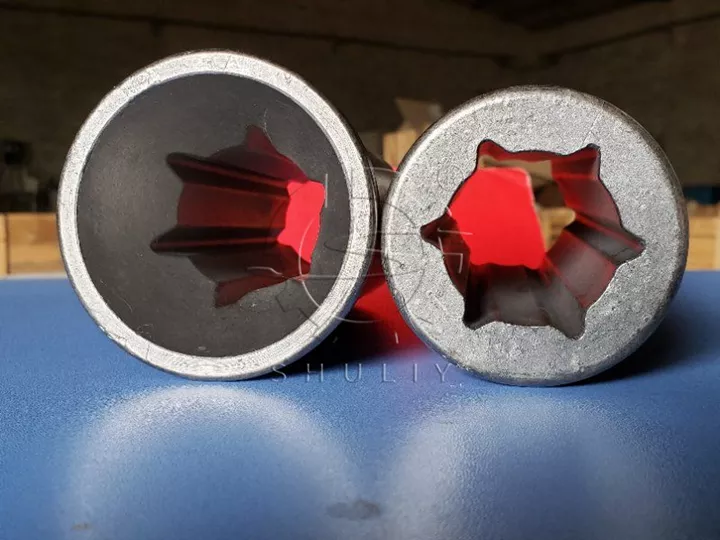

Maßgeschneiderte Formen für die Maschine zur Herstellung von Kohlebriketts

Unsere Kohlepressmaschine kann mit verschiedenen Formen von Formen ausgestattet werden, z. B. fünfeckigen, sechseckigen, dreieckigen, quadratischen, runden, Pflaumenblütenformen usw. Eine kundenspezifische Anpassung ist ebenfalls möglich. Das Bild unten zeigt unsere verschiedenen Formenformen:

Vorteile der Shuliy-Holzkohlebrikettformmaschine

- Zu den Formstilen gehören Pflaumenblüten-, Dreieck-, Viereck-, Rauten- und verschiedene andere Designs, die alle je nach Kundenwunsch angepasst werden können.

- Die Kohlepressmaschine erzeugt minimale Geräusche und weist einen geringen Verschleiß auf. Es liefert eine hohe Leistung, verfügt über eine beeindruckende Festigkeit und sorgt dafür, dass das Endprodukt sehr kompakt ist.

- Die Holzkohlebrikettmaschine ist aus hochwertigem Stahl gefertigt, was die allgemeine Haltbarkeit der Maschine erhöht, Reparaturen erleichtert und einen zuverlässigen Betrieb gewährleistet.

- Das Zubehör ist von guter Qualität. Die Reibahle der Maschine zur Herstellung von Holzkohlebriketts besteht aus legiertem Material und ist dadurch verschleißfest und langlebig.

Fabrikausstellung für Kohleextruder

Shuliy ist ein professioneller Hersteller von Holzkohlebrikettmaschinen. Angenommen, Sie möchten eine große Menge fertiger Holzkohlebriketts herstellen. Wir empfehlen Ihnen eine Holzkohle-Produktionslinie, um Ihnen zu helfen, das Produktionsprojekt reibungslos durchzuführen.

Mit unserem umfassenden Service können wir Sie bei der Gestaltung des Fabriklayoutplans, des Ausrüstungsprogramms, der Installation der Ausrüstung, des Kundendienstes usw. unterstützen.

Bezüglich der Kohle-formenden Ausrüstung produziert unser Unternehmen auch Shisha-Holzkohlemaschinen, Grill-Holzkohleherstellungsmaschinen usw. Für Details klicken Sie bitte Rotary Shisha-Holzkohleherstellungsmaschine für Hookah-Briketts, Holzkohleballpressmaschine für BBQ-Industrie.

Holzkohlebrikettpressmaschine nach Mexiko verkauft

Der Kunde wollte mit der Herstellung von Holzkohlebriketts beginnen. Da es sich um ein neues Geschäft handelt, benötigt der Kunde eine kleine Leistung. Nach der Kommunikation empfehlen wir dem Kunden entsprechend der spezifischen Situation des Kunden die Kohlepressmaschine MBJ180.

Die Hilfsgeräte verfügen über eine Schneider- und Förderband, und wir haben dem Kunden eine PI erstellt. Nachdem wir die Anzahlung des Kunden erhalten hatten, bereiteten wir sofort die Holzkohlebrikettmaschine vor und schickten sie bereits nach Mexiko.

Kontaktieren Sie uns jederzeit

Um den individuellen Bedürfnissen unserer Kunden gerecht zu werden, haben wir eine Reihe hocheffizienter Produktionslinien für die Holzkohlebrikettierung entwickelt und eingerichtet, die sowohl für mittlere und große Holzkohlefabriken als auch für den Heimgebrauch geeignet sind. Wenn Sie interessiert sind, wenden Sie sich bitte an uns. Unser professionelles Team wird Ihnen innerhalb eines Werktages antworten.

Edelstahl-Shisha-Kohlenstoffherstellungsmaschine für Hookah-Brikett-Tabletten

Die von der Shisha produzierten Wasserpfeifenkohletabletten aus Edelstahl...

Rotierende Shisha-Kohlenherstellungsmaschine für Hookah-Briketts

Die rotierende Shisha-Kohlenherstellungsmaschine ist eine automatische Doppelpress-…

Kohlenstoffballenpresse für die BBQ-Industrie

Die Holzkohleball-Pressmaschinen sind dafür ausgelegt, lockere… zu komprimieren

Waben-Kohlemaschine Für Brikett-Formungs-Produktionslinie

Die Waben-Kohlenmaschine dient dazu, die gut aufbereitete Kohle zu betrachten…

Vertikaler Hebe-Karbonisierungsofen für die Kohleherstellungsanlage

Der Hubkohlenstoffofen wird zum Verkohlen von Holz oder…

Horizontaler Karbonisierungsofen für die Verarbeitung von Briketts

Der horizontale Karbonisierungsofen ist eine Art Ausrüstung für…

Kontinuierlicher Kohlenisierungsofen für die Herstellung von Reisschalenbriketts

Der kontinuierliche Holzkohlen-Karbonisierungsofen ist eine ideale Ausrüstung für trockenes…

Sägemehl-Brikettmaschine für Biomasse-Kohlenstoffverarbeitungsanlage

Die Sägemehlbrikettpresse ist dazu konzipiert, Abfallmaterialien zu verdichten…

BBQ-Kohlepresse in der Brikettproduktionslinie

Die BBQ-Kohleverpackungsmaschine ist ein spezialisiertes Gerät...

Multifunktionale Shisha-Hookah-Kohlenstoffverpackungsmaschine zum Verkauf

In der Holzkohleverarbeitungsindustrie wird die Wasserpfeifen-Holzkohleverpackungsmaschine…

Heißes Produkt

Holzschälermaschine Holzstamm-Schälgerät

Ausgestattet mit hochfesten Legierungsklingen und fortschrittlichem Dreh...

BBQ-Kohlepresse in der Brikettproduktionslinie

Eine Holzkohle-BBQ-Verpackungsmaschine ist eine spezialisierte…

Futterpelletmühle für Tierhaltung

Die Futterpelletmühle wird zur Herstellung von Tier… verwendet

Hydraulische Shisha-Kohlenbrikettmaschine für die Kohleformung

Die hydraulische Shisha-Kohlebriquettemaschine ist ebenfalls ein...

Kohlenstoffballenpresse für die BBQ-Industrie

Die Holzkohle-Kugelpresse ist effizient und praktisch …

Multifunktionale Shisha-Hookah-Kohlenstoffverpackungsmaschine zum Verkauf

Die Hookah-Holzkohle-Verpackungsmaschine ist eine spezielle Ausrüstung…

Edelstahl-Shisha-Kohlenstoffherstellungsmaschine für Hookah-Brikett-Tabletten

Die Shisha-Holzkohleherstellungsmaschine ist auch eine…

Automatischer Sägewerk-Maschine für die Holzrecyclinganlage

Die Sägewerksmaschine schneidet größere Stämme in…

Kohlegemischmaschine für die Brikettformanlage

Holzkohle-Schleifmaschine hat die Funktionen des Zerkleinerns,…