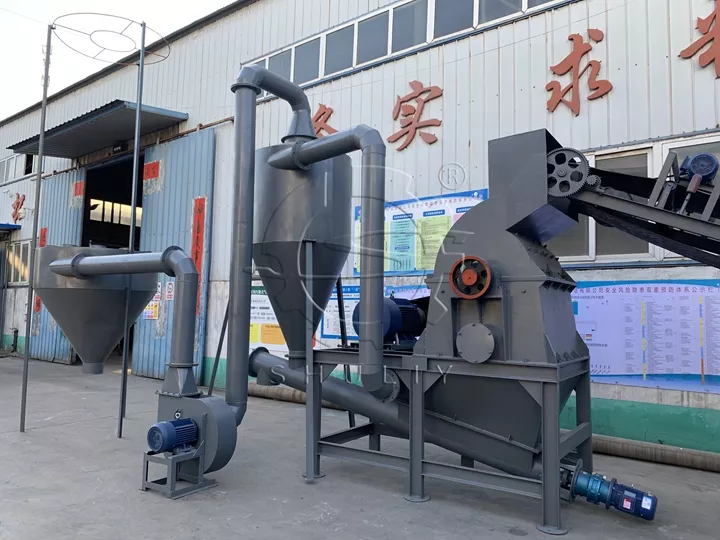

Talaş Üretim Tesisinde Büyük Çekiçli Değirmen Kırıcı

Çekiçli değirmen parçalayıcı | Ahşap çekiç kırma makinesi

Talaş Üretim Tesisinde Büyük Çekiçli Değirmen Kırıcı

Çekiçli değirmen parçalayıcı | Ahşap çekiç kırma makinesi

Bir Bakışta Özellikler

Tahta çekiçli değirmen kırıcısı, büyük ağaç talaşlarını, odun peletleri ve talaş üretimi için gerekli olan 3-5 mm'lik talaşlara parçalamak için makine içindeki çekiçlerin yüksek hızda dönmesini kullanarak çalışır.

Bu makine sert, yumuşak ve hafif aşındırıcı malzemeleri kırarak uygun nem seviyelerine sahip eşit boyutlu parçacıklar elde etme kapasitesine sahiptir. Ağaç işleme, biyokütle pelet üretimi, hayvan yemi işleme, ahşap levha üretimi ve diğer çeşitli endüstrilerde geniş uygulama alanı bulur.

Diğer kırıcı türleriyle karşılaştırıldığında ahşap çekiçli kırıcı, büyük kırma oranı, yüksek üretim kapasitesi, tutarlı parçacık boyutu ve düşük enerji tüketimi gibi çeşitli avantajlar sunar. Sürüş yöntemine bağlı olarak çekiçli kırıcılar elektrikli, dizel, PTO tahrikli ve daha fazlasına ayrılabilir. Ek olarak, daha fazla hareket kabiliyeti sağlamak için tekerlekli bir taban dahil edilebilir.

Çekiç kırma makinesinin geniş uygulaması

Çekiçli değirmen kırıcısı yapışkan, yağlı veya aşırı nem içeriğine sahip hammaddelerin işlenmesi için tasarlanmamıştır. Ayrıca hammaddelerin metal veya diğer sert yabancı maddelerden arındırılmış olması gerekir.

Çekiçli kırıcı, ahşap, ağaç kabuğu, talaş, talaş ve tahta gibi tipik malzemeleri kırmanın yanı sıra mahsul saplarını, mısır, fındık kabuklarını, yer fıstığı kabuklarını ve daha fazlasını da işleyebilir.

Ayrıca, ağacın çapı veya kalınlığı 4 cm'yi aşarsa, kalın ağacı daha küçük parçalara ayırmak için önce bir yonga makinesi kullanılması genellikle önerilir. (İlgili Yazı: Talaş Üretim Tesisi İçin Yonga Makinesi>>) Bu yaklaşım sadece çıktıyı artırmakla kalmaz, aynı zamanda makinenin aşınmasını ve yıpranmasını da en aza indirir.

Çekiçli değirmen kırıcı bitmiş ürün

Tahta çekiçli değirmende işlendikten sonra nihai ürün genellikle ezilmiş ağaç parçacıkları veya lifli malzemelerdir ve bunun özel şekli ve kullanımı, ham madde türüne ve işleme gereksinimlerine bağlıdır. Aşağıda bazı olası bitmiş ürünler yer almaktadır:

- Odun peletleri: Bu peletler genellikle odun pelet yakıtı gibi biyokütle enerji üretimi, ısıtma, enerji üretimi vb. için kullanılır.

- Biyokütle Peletleri: Ahşap çekiçli değirmen ayrıca saman, bambu, mısır saplarını vb. biyokütle peletlerine işleyebilir. Bu peletler hayvan yemi, organik gübre vb. olarak kullanılabilir.

- Odun hamuru: Bir odun çekiçli talaş değirmeni aynı zamanda kağıt, sunta, sunta ve diğer ahşap ürünlerinin üretimi için ahşabı odun hamuru haline getirebilir.

Çekiçli değirmen kırıcı ana yapısı

Dışarıdan, makinenin ana kısmı girişi, kırma odasını ve boşaltma portunu içerir.

- Giriş: Hammadde olan odun ezilmek üzere makineye konur.

- Kırma odası: Ağaç kırmanın ana alanıdır ve içinde birkaç adet döner çekiç bıçağı veya çekiç bulunur.

- Deşarj portu: Kırılan ağaç talaşları boşaltma ağzından makineden boşaltılır.

Destek plakası: çekiç bıçağının çalışma sürecinin yüksek yoğunluklu operasyonunda, makinenin arka kabuğunu korumak için içine bir destek plakası ekledik, bu da makinenin kolayca hasar görmemesini, daha aşınmaya dayanıklı olmasını ve daha uzun ömürlü olmasını sağlar.

Elekler: ana rolü çıktı boyutunu düzenlemektir ve çeşitli açıklıklara sahip elek ayarlanarak farklı boyutlarda nihai ürünler elde edilebilir.

Siklon toz toplayıcı: malzemeyi kırdıktan sonra bir toz toplayıcı ile donatılabilir, malzemenin fan tarafından toz toplayıcıya üflenmesi, torba ile birlikte, rolü kirliliği önlemek için tozu toplamak.

Ahşap çekiçli değirmen kırıcının avantajları

- Büyük bir çekiçli değirmen kırıcısının çıkışı küçük bir kırıcının üç ila dört katına ulaşabilir. odun kırıcı.

- Çeşitli veya eşit olmayan boyutlardaki ham maddeleri tutarlı ahşap parçacıklarına dönüştürebilir.

- Farklı hammadde öğütme gereksinimlerini karşılamak için çeşitli elek elekleri seçilebilir.

- Çekiçli değirmen kırma makinesi, güvenlik göz önünde bulundurularak özenle tasarlanmıştır ve koruyucu güvenlik özellikleri içerir.

- Çekiçler uzun süreli kullanım için üretildiğinden aşınmaya yatkındır. Darbelere karşı dayanıklılığı artırmak için çekiç kafasının köşeleri aşınmaya dayanıklı bir alaşımla güçlendirilmiştir.

Çekiçli ahşap kırıcı nasıl çalışır?

Çekiçli kırıcı çalıştığında, motor döner mili döndürerek ona bağlı çekiçlerin hızla dönmesini sağlar. Ahşap malzemeler, girişten kırma odasına girer ve yüksek hızlı dönen çekiçlerin kuvvetiyle hızla kırılır.

Elde edilen ezilmiş malzeme daha sonra makinenin içindeki bir ağdan elenir. Eleğin açıklıklarının boyutu, nihai ürünün parçacık boyutunu kontrol edecek şekilde ayarlanabilir. Daha küçük parçacıklar ağdan geçebilirken, daha büyük parçacıklar daha fazla ezilmek üzere makinenin içinde kalır.

Çekiçli ağaç parçalayıcının teknik verileri

| Modeli | SL-60 | SL-70 | SL-80 | SL-90 | SL-1000 | SL-1300 |

| Güç(kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Çekiçler (adet) | 30 | 40 | 50 | 50 | 105 | 105 |

| Fan(kw) | 7.5 | 7.5 | 11 | 22 | ||

| Toz giderici (adet) | 5 | 5 | 5 | 5 | 14 | 14 |

| Siklon çapı(M) | 1 | 1 | 1 | 1 | 1 | 1 |

| Kapasite (T/saat) | 0.8-1 | 1-1.5 | 1.5-2 | 2-3 | 3-4 | 4-5 |

Basit tasarımımız, kompakt boyutumuz, kullanıcı dostu işletimimiz ve minimum bakım gereksinimimiz, bu makineyi evler, çiftlikler veya küçük pelet değirmenleri için en iyi seçim haline getiriyor. Boyutu özel ihtiyaçlarınıza uyacak şekilde uyarlayabiliriz. Ahşap çekiçli değirmen kırma makinesinin en güncel fiyatları için iletişime geçmekten çekinmeyin!

Odun Tozu Kömür Makinesi Biyokütle Kömürü İşleme Hattı İçin

Talaş briket makinesi, atık malzemeleri sıkıştırmak için tasarlanmıştır…

Talaş Tozu Kurutma Tesisi İçin Dönme Tambur Kurutucu Makinesi

Döner tamburlu kurutucu makinesi yaygın olarak buharlaştırmak için kullanılır…

Odun Kırma Makinesi Odun Tozu Yapmak İçin

Ağaç kırma makinesinde yüksek hızlı dönen bıçaklar ve…

Otomatik Kestane Makinesi Ahşap Geri Dönüşüm Tesisi İçin

Testere değirmeni makinesi dairesel veya bantlı bir testere kullanır…

Odun Soyma Makinesi Ahşap Kütük Soyma Ekipmanı

Yüksek mukavemetli alaşımlı bıçaklarla ve gelişmiş teknolojiyle donatılmış ahşap kabuk soyucu…

Hayvan Yataklığı İçin Ahşap Tıraşlama Makinesi

Tahta tıraş makinesi ahşabı dönüştürmek için tasarlanmıştır…

Ahşap Kırıcı Makinesi Talaş Üretim Tesisi İçin

Ahşap parçalama makinesi, ahşabı parçalara ayırmak için tasarlanmıştır,…

Kapsamlı Kırıcı Büyük Kapasiteli Ahşap Parçalayıcı Makinesi

Kapsamlı kırıcı, büyük parçaları kırmak için tasarlanmıştır…

Hayvan Besi İçin Yem Pelet Değirmeni Makinesi

Yem pelet değirmeni makinesi bir tür ekipmandır…

Otomatik Ahşap Palet Pres Makinesi Satılık

Ahşap palet pres makinesi öne çıkan ürünümüzdür, özellikle…

Sıcak Ürün

Otomatik Isı Daraltıcı Film Kömür Briquette Paketleme Makinesi

Isıl büzüşmeli kömür briket paketleme makineleri iyi uygundur…

Kömür Öğütme Makinesi Briquet Şekillendirme Tesisi İçin

Kömür öğütme makinesi kırma, … işlevlerine sahiptir

Petek Nargile Kömürü Üretimi İçin Briquette Kömür Kurutucu

Briket kömürü kurutucusu buharlaşmayı ifade eder…

Pirincin Külünden Kömür Yapımı İçin Sürekli Kızıltaş Fırını

Sürekli kömür karbonizasyon fırını, ideal bir ekipmandır…

Barbekü Kömürü Paketleme Makinesi Kömür Presleme Hattında

Barbekü kömürü paketleme makinesi, özel bir…

Çok Fonksiyonlu Şişa Nargile Kömürü Paketleme Makinesi Satışta

Nargile kömürü paketleme makinesi özel bir ekipmandır…

Hayvan Besi İçin Yem Pelet Değirmeni Makinesi

Yem pelet değirmeni hayvanlar için yiyecek yapmak üzere kullanılır…

Döner Şişa Kömürü Yapma Makinesi Hookah Kömürü İçin

Döner nargile kömür yapma makinesi çift baskı mekanizmasına sahiptir…

Odun Soyma Makinesi Ahşap Kütük Soyma Ekipmanı

Yüksek mukavemetli alaşımlı bıçaklar ve gelişmiş döner… ile donatılmış