特点一览

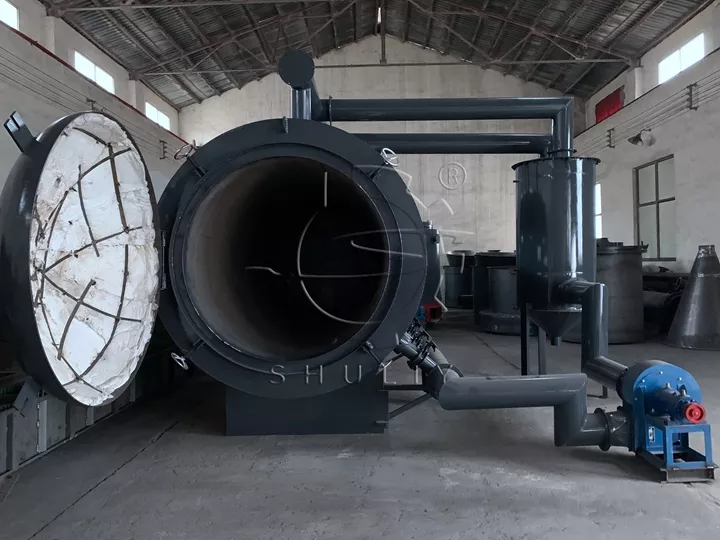

卧式炭化炉与立式炭化炉一样,是一种将木材等原料炭化的设备。因炭室布置水平放置,以降低机器高度,故称为卧式炭炉。因此装载原材料更加方便。

卧式炭化炉内的原料在高温、无氧的环境下通过热解转化为木炭。每炉产量可达2.5-3t/12-14H。

与其他气流炭化炉一样,它还包括烟气回收系统。炭化过程中产生的烟雾进入净化器,然后被点燃以加热炉子。此外,多余的气体还可作为锯末烘干机、锅炉等的热源。

您可以通过点击立式提升炭化炉了解立式炭化炉的详细信息。

块炭机有什么用途?

块炭机可加工原木、树枝、树根、竹子、生物质煤球、玉米芯、椰子壳、坚果壳、花生壳、核桃壳、锯材、玉米秆、甘蔗渣、稻壳、竹片、高粱秆,许多其他材料。

成品深加工:除生物质压块外,其他物料需要用木炭粉碎机进一步粉碎,然后才能通过木炭挤压机、水烟炭机、木炭球压球机等设备进行压制成型。

卧式炭化炉成品

卧式木炭炉的成品通常是型煤和各种不规则形状的炭化材料。以木质生物质为原料,卧式炭化炉可制备优质木质生物质木炭。这种木炭颜色深,质地坚硬,燃烧时释放稳定的热能,常用于取暖、炊事和工业燃烧。

硬木炭化炉的组织

卧式炭化炉主要由炭化室、加热设备、搁架、烟气净化系统、控制系统、排渣装置、进料口、出料口等组成。另外,外炉和内炉之间还有一层隔热棉夹层。

卧式木炭机工作流程

卧式炭化炉控制炭化室内的温度、时间和环境气氛,通过一系列化学反应释放原料中的水分和挥发性物质,形成稳定的木炭产品。

- 将原料放入卧式炭化炉炭化室。

- 启动加热设备(如燃烧炉、燃气炉或电加热器)。

- 在高温、无氧的环境下,原料开始进行碳化反应。

- 炭化过程中会产生大量的烟雾和挥发性物质。卧式炭炉有排气系统,收集并处理产生的废气。

- 木炭机配备自动控制系统,可监控和调节炭化过程中的温度、压力和烟雾排放。

- 卧式炭化炉配有排渣装置,收集灰分和焦油。

- 完成碳化过程后取出成品木炭。

木炭炭化炉技术资料

| 模型 | 每炉容量 | 方面 | 重量 |

| 1300 | 900-1200公斤/12-14小时 | 3*1.7*2.2M | 2500公斤 |

| 1500 | 1500-2000公斤/12-14小时 | 4.5*1.9*2.3M | 4000公斤 |

| 1900 | 2500-3000公斤/12-14小时 | 5*2.3*2.5M | 5500公斤 |

卧式炭化炉特点

- 主机体积大,炭化率高,生产能力强,每小时炭化3-10吨。

- 适用多种原料:块炭机可处理多种原料,包括木材、竹子、果壳、农业废弃物等。

- 成本低、实用性高,满足初次创业者的投资需求。

- 块炭炉机采用特种耐高温不锈钢材质,坚固耐用,不变形,保温性能好。

卧式原木炭化炉发货

舒立公司的块状炭化炉已销往厄瓜多尔、突尼斯、印度尼西亚、肯尼亚、意大利、黎巴嫩、乌干达等许多国家。这是机器的包装和运输图片:

我厂还生产连续式炭化炉。如果您对我们的机器感兴趣,请随时与我们联系,我们将为您提供更详细的信息和机器报价。

热门产品

木材包装生产厂用托盘块机

可处理的木块标准尺寸为……

液压水烟炭压块机,用于煤炭成型

液压水烟炭压球机也是一个…

多功能大容量破碎机,用于木材粉碎

综合破碎机旨在分解…

锯末制造厂用木屑机

木材削片机的设计是用于破碎…

自动锯木机,用于木材回收厂

锯木机将较大的原木切割成……

连续炭化炉,用于稻壳炭制作

连续木炭炭化炉是一种理想的设备…

燃料生产线用炭饼机

木炭压块机,也称为压砖机,……

多功能水烟壶炭包装机,出售中

水烟炭包装机是一种专用设备…

垂直提升炭化炉,用于炭厂

制炭炉用于炭化……