Maswali Yanayoulizwa Mara Kwa Mara na Tahadhari Kuhusu Utumiaji wa Mashine ya Kufunga Mbao

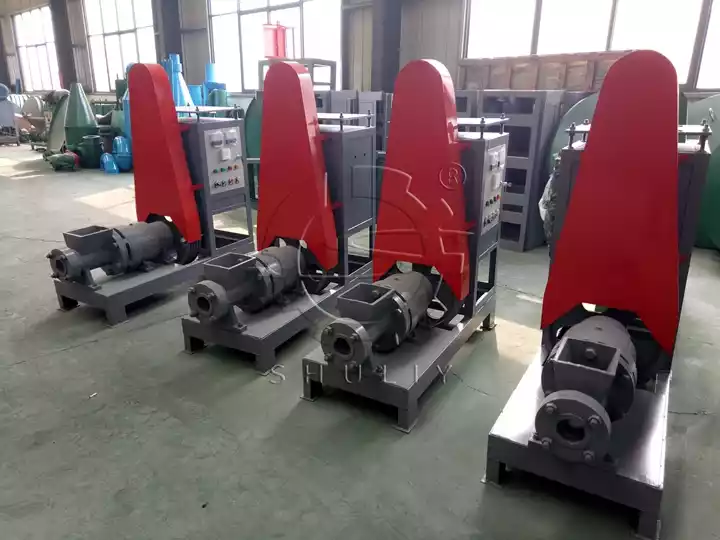

Mashine ya kubana mbao ni kifaa kinachoweza kutoa malighafi za mbao zilizopondwa kuwa maumbo ya joto la juu. Bidhaa nyingi za kumaliza zilizotolewa zitachakatwa kuwa vipande vya makaa kupitia tanuri ya kuchomea na kutumiwa kama mafuta. Mashine ya kutengeneza vipande ina utendaji thabiti wa kufanya kazi kwa joto lililowekwa na ina faida za muundo unaofaa, operesheni rahisi, na matengenezo.

Malighafi Zilizochakatwa na Mashine ya Kufunga Mbao

Malighafi za mashine ya kutengeneza vipande vya mbao za mbao ni pana sana, kama vile nyasi za mazao vijijini, nyasi za pamba, bua la ufuta, nyasi za mahindi, na kokwa la mahindi. Vitu vya ziada kutoka kwa viwanda vya samani, viwanda vya mianzi, viwanda vya vijiti vya kula, n.k. Pia kuna matawi yaliyopunguzwa kutoka kwa mashamba ya miti, bustani, n.k. Malighafi hizi zinahitaji kupondwa kwanza na kipondaji cha nyundo cha mbao.

Maswali Yanayohusiana Nayo Ya Kutengeneza Briquette ya Mashine ya Sawdust

- Je, urefu wa fimbo ya mbao unaweza kubadilishwa?

Ndiyo, nafasi ya baffle inaweza kudhibitiwa, na urefu wa baffle ni 10-15cm. - Pato la mashine ni nini?

Pato la aina hii ya mashine ya briquetting ya kuni kwenye soko ni 250kg / h. Ikiwa mteja anasisitiza juu ya pato kubwa, vitengo viwili vinapendekezwa. - Kwa nini malighafi haiwezi kuwa mvua sana?

Malighafi itashikamana na ond, haiwezi kufinywa, haiwezi kutengenezwa, na itasababisha uchakavu mkubwa zaidi. - Je, ni molds kwa mashine ya kutengeneza fimbo?

Hexagonal zina mashimo, za mraba zina mashimo, na zisizo na mashimo haziwezi kufanywa. - Je, ni msongamano gani wa mashine ya kutengeneza briquette ya vumbi la mbao?

Inahusiana sana na malighafi. Kadiri malighafi inavyozidi kuwa ngumu, ndivyo msongamano unavyoongezeka, 1-1.3t/m³.

Tahadhari Unapotumia Briquette Press Machine

- Wakati wa uzalishaji, makini ikiwa sasa motor na voltage ni ya kawaida ili kuzuia uharibifu wa motor.

- Ni marufuku kabisa kusimama mbele ya bandari ya kutokwa wakati mashine inapoanza.

- Saketi za umeme zinapaswa kuwekwa kavu na safi, na usambazaji wa umeme unapaswa kukatwa wakati wa kuzima.

- Ni marufuku kabisa kuruhusu mawe na filings za chuma kuingia kwenye hopper. Ikiwa kuna ukiukwaji wowote, simamisha mashine ya kuwekea mbao mara moja.

- Sehemu zote za lubricated zinapaswa kulainisha mara moja kila baada ya miezi 2.

- Ikiwa fuselage haijawekwa vizuri, ni marufuku kabisa kuiwasha!

Kwa maelezo zaidi kuhusu mashine ya kuwekea briquet za mbao, tafadhali tembelea tovuti hii na ujisikie huru kuwasiliana nasi, tutakujibu kwa haraka zaidi.