Mashine ya Briquette ya Mkaa ya Hydraulic ya Shisha Kwa Kutengeneza Makaa ya Mawe

Shisha mashine ya kuchapa mkaa | Mashine ya briquette ya mkaa ya hookah

Mashine ya Briquette ya Mkaa ya Hydraulic ya Shisha Kwa Kutengeneza Makaa ya Mawe

Shisha mashine ya kuchapa mkaa | Mashine ya briquette ya mkaa ya hookah

Vipengele kwa Mtazamo

Mashine ya majimaji ya briquette ya mkaa ya shisha hutumia teknolojia ya majimaji kukandamiza na kuunda malighafi iliyosafishwa kabla kuwa briketi thabiti za mkaa wa hookah.

Mahitaji ya malighafi zinazotumiwa katika mkaa wa kuvuta maji ni magumu sana. Ili kuhakikisha ubora wa bidhaa ya mwisho, malighafi zinazotumiwa kwa kawaida ni pamoja na unga wa mkaa wa mianzi, unga wa mkaa wa matunda, na unga wa makaa wa ganda la nazi, miongoni mwa mengine.

Mkaa wa hookah uliokamilishwa unaozalishwa na mashine hii unajivunia wiani wa juu, umbo bora, na mwonekano wa kuvutia. Zaidi ya hayo, inawaka kwa urahisi, haina harufu, na inatoa muda mrefu wa kuchoma. Kwa kutumia molds zinazoweza kubinafsishwa, wateja wanaweza kuunda maumbo mbalimbali ya flakes ya mkaa ili kukidhi matakwa yao.

Kwa shinikizo kubwa na wiani wa hali ya juu, mashine inaweza kubana na kuunda kwa sekunde moja. Mashine yetu ya briquette ya shisha ya hydraulic ni rahisi kutumia na ina utendaji bora, ambayo inasaidiwa na kupendwa na wateja wengi. Inafanana katika kazi na mashine ya kutengeneza makaa ya shisha ya chuma cha pua. Mashine yetu ya kubana makaa ya shisha ya hydraulic ina mifano na mitindo tofauti.

Malighafi ya mashine ya kuchapisha mkaa wa majimaji

Malighafi inaweza kujumuisha mkaa, makaa ya mawe, coke, na vitu sawa. Vinginevyo, zinaweza kujumuisha biomasi yenye utajiri wa lignin kama vile maganda ya nazi, mianzi, maganda ya mpunga, na vumbi la mbao. Mkaa unaotokana unaweza kutumika kwa kuchoma nyama au kama mafuta ya kuvuta sigara.

Mashine ya mkaa ya hydraulic hookah bidhaa za kumaliza

Mashine yetu ya kutengeneza mkaa wa hookah inaweza kuzalisha briketi za mkaa katika maumbo mbalimbali, ikiwa ni pamoja na mraba, mviringo, pete, almasi, pembetatu, silinda, nk. Miongoni mwa ukubwa wa kawaida ni:

- Sura ya mraba: 20*20*20mm, 25*25*25mm.

- Umbo la pande zote: kipenyo 30mm, 33mm, 34mm, 35mm, 40mm.

Muundo mkuu wa mashine ya mkaa ya shisha ya hydraulic

Mashine ya briquette ya shisha ya hydraulic ya mkaa kwa kawaida hujumuisha vipengele kadhaa muhimu: silinda ya hydraulic, pampu ya hydraulic, valve hydraulic, tezi, mold ya briquette, na mfumo wa udhibiti.

Silinda ya majimaji hutumika kama kipengele kikuu, kwa kutumia shinikizo kutoka kwa pampu ya majimaji kuendesha pistoni na kuunda nguvu. Wakati huo huo, gland na mold ya briquette ni muhimu kwa kuhimili shinikizo na kuunda briquettes ya mkaa.

Mold ya mashine ya kuchapisha briquette ya mkaa

Viumbe vya mashine hii ya briketi ya shisha ya majimaji huwa na umbo la mraba na mviringo. Hata hivyo, pia tunatoa chaguo za kubinafsisha ukungu katika maumbo, ruwaza, nembo na saizi tofauti ili kukidhi mahitaji yako mahususi.

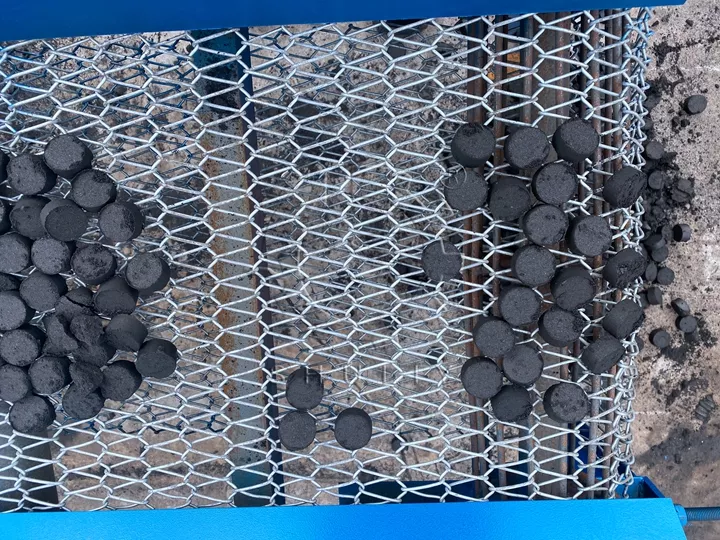

Tabia ya ukanda wa usafirishaji wa mashine ya kubana makaa ya hydraulic

Mashine ya briquette ya shisha ya hydraulic ya mkaa inakuja na ukanda wa usafiri, ambao unaweza kuwa ukanda wa mesh au gorofa. Ukanda wa matundu ni mzuri katika kuruhusu vumbi la ziada la makaa ya mawe kupita.

Vigezo vya mashine ya kutengeneza mkaa wa shisha ya hydraulic

Paramita za kiufundi za mashine za makaa ya shisha za hydraulic zinaweza kutofautiana kulingana na mfano na mahitaji ya muundo. Ifuatayo ni baadhi ya paramita za kiufundi za kawaida za mfano wa SL-HS-2 zinazoweza kupatikana kwa mashine za makaa ya shisha za hydraulic. Kwa mifano zaidi ya mashine, tafadhali wasiliana nasi.

Mfano: SL-HS-2

- Shinikizo: 80 tani

- UzitoUzito: 2800 kg

- Nguvu ya pampu ya majimaji: 18.5kw

- Kipimo kikuu cha mwenyeji: 1000*2100*2000mm

- Nguvu ya kulisha0.75kw

- Nguvu ya kutokwa0.75kw

- Kutoa conveyor: 800*850*1850mm

- Kudhibiti ukubwa wa baraza la mawaziri: 530*900*1100mm

- Uwezo:

- Vipande 42 kwa wakati, mara 3 kwa dakika (umbo la pande zote)

- Vipande 44 kwa wakati, mara 3 kwa dakika (umbo la ujazo)

Je, mashine ya kutengeneza mkaa ya hydraulic hookah inafanya kazi gani?

Maandalizi ya malighafi

Kwanza, malighafi inayotumiwa kuandaa mkaa wa hooka inahitaji kutayarishwa. Hizi ni chips za mbao, chips za mianzi, au malighafi nyingine za nyuzi ambazo zimechanganywa, kusagwa, na kusindika; viungo, mimea, nk pia inaweza kuongezwa.

Kuchanganya binder

Malighafi huchanganywa na binder, ambayo inaweza kuwa gamu ya mboga, wanga, nk, ambayo hutoa nguvu ya kuunganisha inayohitajika kwa ukingo.

Uendeshaji wa mfumo wa majimaji

Mashine ya briquette ya mkaa ya hydraulic shisha ina mfumo wa ndani wa majimaji, ambayo inajumuisha tank ya majimaji, pampu ya majimaji, silinda ya majimaji, na vipengele vingine. Mfumo wa majimaji utatoa maji ya shinikizo la juu (kawaida mafuta ya hydraulic), ambayo huingizwa kwenye silinda ya majimaji kupitia pampu ya majimaji.

Ukingo wa compression

Wakati kioevu kinapoingia kwenye silinda ya hydraulic, silinda inasisitizwa na kioevu, ambayo hujenga nguvu. Nguvu hii hupitishwa kwa malighafi katika chumba cha ukingo kupitia plunger au pistoni, ikikandamiza malighafi katika umbo fulani wa briquette ya mkaa.

Shinikizo la kutolewa

Mara tu briquettes za makaa zinapoundwa na mfumo wa majimaji huacha kusambaza maji, shinikizo katika silinda ya hydraulic hupungua, ikitoa shinikizo kwenye briquettes ya mkaa.

Kukausha na ufungaji

Briquettes ya mkaa inahitaji kukaushwa ili kuondoa unyevu kutoka kwao, kuongeza thamani ya kaloriki, na kuboresha utulivu. Kwa kuongeza, inaweza kutibiwa kwa ladha, nk kama inahitajika.

Mfumo wa majimaji huhakikisha kwamba briketi za mkaa zinabaki thabiti na thabiti, hivyo kumpa mvutaji hooka moshi wa hali ya juu na uzoefu wa jumla wa kuvuta sigara.

Makala ya mashine ya mkaa ya hooka ya hydraulic

- Mashine hii ina pampu ya hydraulic yenye shinikizo la juu ambayo huongeza kwa kiasi kikubwa wiani wa bidhaa. Briquettes ya mkaa inayotokana ni nguvu na inakabiliwa na kuvunjika wakati wa matumizi.

- Wateja wana uwezo wa kurekebisha shinikizo la ukingo na msongamano wa kifaa ndoano vipande vya mkaa ili kukidhi mahitaji yao maalum.

- Molds ni ubora wa juu na usahihi, huzalisha briquettes na sura kamili na uso laini.

- Kwa vali ya majimaji na mfumo wa kudhibiti, inaruhusu usimamizi sahihi wa shinikizo, kiwango cha mtiririko, na wakati wa kushinikiza.

- Mfumo hutumia udhibiti wa PLC, na skrini ya kugusa ya baraza la mawaziri huonyesha hali ya kufanya kazi, na kuifanya iwe rahisi kwa mtumiaji kwa marekebisho ya haraka ya vigezo na kuwezesha uendeshaji otomatiki kikamilifu.

- Sehemu nzima imejengwa kutoka kwa chuma cha pua, kuhakikisha kuegemea na uimara.

Kama inavyoonyeshwa kwenye video hapo juu, kiwanda chetu kinatengeneza aina mbalimbali za mashine za mkaa za hookah. Unaweza kuchagua mashine inayotosheleza mahitaji yako kulingana na hali ya matumizi yako, ukubwa wa uchakataji, mbinu ya uzalishaji na zaidi. Jisikie huru kuwasiliana nasi wakati wowote.

Mashine ya Kutengeneza Mkaa ya Shisha ya Chuma cha Pua kwa Vidonge vya Briquette za Hookah

Vidonge vya mkaa za hookah zinazotengenezwa na mashine ya shisha ya chuma cha pua ya majimaji…

Mashine ya Kutengeneza Mkaa ya Shisha ya Rotary kwa Briquettes za Hookah

Mashine ya kuunda mkaa wa shisha ya mzunguko ni kiotomatiki, yenye bonyeza mara mbili…

Mashine ya Kufunga Mkaa ya Shisha ya Kazi nyingi Inauzwa

Inom kolbearbetningsindustrin, förpackningsmaskinen för vattenpipa kol...

Shisha Kol Produktionslinje Hookach Briquette Tillverkning Maskiner

Shisha kolproduktionslinjen omvandlar råvaror till högkvalitativt...

2 Hookah Kol Tablet Press Maskiner Exporteras Till Algeriet

Recently, a shisha lounge from Algeria decided to purchase a…

Jakartan Kund Introducerar Högsnabbhet Hookah Kolets Roterande Tableting Maskin

Recentement, vårt företag har färdigställt produktionen av en vattenpipa kol...

Leverans Av Shisha Kol Tablet Press Maskin Till Marocko Går Smidigt

Goda nyheter! Shuliy Group har framgångsrikt skeppat 2 uppsättningar av...

Mteja Mwandamizi wa Kireno Alinunua Mashine za Mkaa ya Hookah kwa Mstari wa Uzalishaji

Katika miaka ya hivi karibuni, Ureno imehimiza kwa nguvu mazingira ya kijani na nishati mbadala…

Mashine ya Briquette ya Mkaa kwa Mstari wa Uzalishaji wa Mafuta

Mashine ya briquette ya mkaa imeundwa kubana makaa au…

Mashine ya Press ya Mpira wa Mkaa kwa Sekta ya BBQ

Mashine za kusindika mipira ya mkaa zimetengenezwa kubana nyenzo zisizofungwa…

Bidhaa Moto

Molino de Carbón para Planta de Moldeo de Briquetas

Mashine ya kusaga mkaa ina kazi za kusaga,…

Kiwanda cha Kunyanyua Makaa ya Mawe ya Hydraulic kwa Uundaji wa Makaa

Mashine ya briquette ya mkaa ya shisha ya hidroliki pia ni…

Mashine ya Kuondoa Maganda ya Mbao kwa Vifaa vya Kuondoa Mbao

Imewekwa na mapanga ya alloy yenye nguvu kubwa na mzunguko wa kisasa…

Máquina Automática de Embalaje de Briquetas de Carbón con Película Retráctil de Calor

Mashine za kufungasha briquette za makaa kwa njia ya shrink zinafaa vizuri…

Kikavu cha Briquette ya Mkaa kwa Uzalishaji wa Makaa ya Shisha ya Nyuki

Kikaushio cha mkaa cha Briquette kinarejelea uvukizi wa…

Mashine ya Kutengeneza Mkaa ya Shisha ya Rotary kwa Briquettes za Hookah

Mashine ya mkaa ya shisha ya mzunguko ni ya bonyeza mara mbili…

Mashine ya Crusher ya Mbao kwa Kutengeneza Sawdust

Mashine ya kusaga mbao ina visu vinavyozunguka kwa kasi...

Tanuru ya Kaboni ya Kuendelea kwa Kutengeneza Mkaa wa Kichwa cha Mpunga

Kontinuerlig trähärdning sågfurna är en ideal utrustning…

Mashine ya Briquette ya Mkaa kwa Mstari wa Uzalishaji wa Mafuta

Mashine ya briquette za makaa, pia inajulikana kama briquette…