Tanuru Mlalo la Kuchangamsha Mkaa Kwa Ajili ya Kusindika Mkaa Bonge

Mashine ya kutengeneza mkaa ya mlalo | Tanuru ya kaboni ya kuni ya mtiririko wa hewa

Tanuru Mlalo la Kuchangamsha Mkaa Kwa Ajili ya Kusindika Mkaa Bonge

Mashine ya kutengeneza mkaa ya mlalo | Tanuru ya kaboni ya kuni ya mtiririko wa hewa

Vipengele kwa Mtazamo

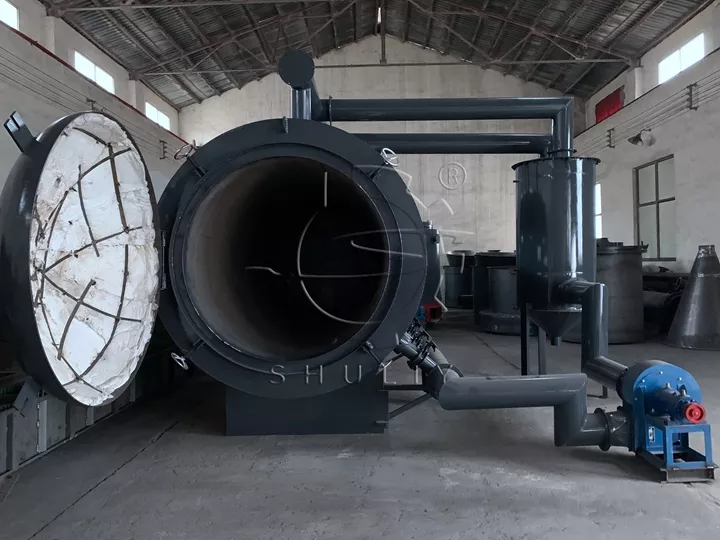

Tanuru ya uwekaji kaboni iliyo mlalo ni aina ya vifaa vya kuunguza kuni na malighafi nyingine kama vile tanuru ya wima ya kaboni. Inaitwa tanuru ya mkaa ya usawa kwa sababu mpangilio wa chumba cha mkaa umewekwa kwa usawa, ili kupunguza urefu wa mashine. Kwa hiyo ni rahisi zaidi kwa kupakia malighafi.

Malighafi katika tanuru ya usawa ya kaboni hubadilishwa kuwa mkaa kwa pyrolysis katika mazingira ya juu ya joto na oksijeni. Pato la kila tanuru inaweza kuwa hadi 2.5-3t/12-14H.

Sawa na vinu vingine vya utiririshaji kaboni wa hewa, pia inajumuisha mfumo wa kuchakata moshi. Moshi unaozalishwa katika mchakato wa kaboni huingia kwenye kisafishaji na kisha kuwashwa kwa ajili ya kupokanzwa tanuru. Kando na hilo, gesi isiyohitajika inaweza kutumika kama chanzo cha joto kwa dryer ya vumbi, boiler, nk.

Unaweza kujifunza taarifa za kina kuhusu tanuri za kuchoma kaboni za wima kwa kubofya Tanuri ya Kuchoma Kaboni ya Mwongozo Kwa Kiwanda cha Kutengeneza Makaa ya Mawe.

Je, mashine ya kutengeneza mkaa bonge ina matumizi gani?

Mashine ya kutengeneza bonge ya mkaa inaweza kusindika magogo ya mbao, matawi, mizizi, mianzi, briketi za majani, visehemu vya mahindi, maganda ya nazi, maganda ya njugu, maganda ya karanga, maganda ya walnut, mbao zilizokatwa kwa msumeno, mabua ya mahindi, magunia, pumba za mpunga, mabua ya mianzi, mabua ya mtama. , nyenzo nyingine nyingi.

Usindikaji zaidi wa bidhaa iliyokamilishwa: Isipokuwa kwa briketi za biomasi, vifaa vingine vinahitaji kusagwa kwa uangalifu kwa kutumia kipasua kaboni. Baada ya hapo, vinaweza kubanwa na kuumbwa tu na mashine ya kutolea nje ya kaboni, mashine ya kaboni ya shisha, mashine ya kubana kaboni ya mpira, na vifaa vingine.

Bidhaa iliyokamilishwa ya tanuru ya usawa ya kaboni

Bidhaa za kumaliza za tanuu za mkaa za usawa ni kawaida briquettes na maumbo mbalimbali yasiyo ya kawaida ya vifaa vya kaboni. Kwa kutumia majani ya kuni kama malighafi, tanuu za uwekaji kaboni mlalo zinaweza kuandaa mkaa wa hali ya juu wa kuni. Aina hii ya mkaa ina rangi nyeusi, umbile mgumu, na hutoa nishati thabiti ya joto inapochomwa, ambayo hutumiwa kwa kawaida kupasha joto, kupikia, na mwako wa viwandani.

Shirika la tanuru ya kaboni ya mbao ngumu

Tanuru ya uwekaji kaboni mlalo hujumuisha chumba cha kukaza kaboni, vifaa vya kupasha joto, rafu, mfumo wa kusafisha gesi ya moshi, mfumo wa kudhibiti, kifaa cha kumwaga maji ya slag, mlango wa kulisha na mlango wa kutoa. Kwa kuongeza, kuna safu ya sandwich ya pamba ya kuhami kati ya jiko la nje na jiko la ndani.

Mtiririko wa kazi wa mashine ya mkaa ya kuni ya usawa

Tanuru ya uwekaji kaboni mlalo hudhibiti halijoto, wakati na angahewa iliyoko kwenye chemba ya ukaa ili kutoa unyevu na dutu tete katika malighafi na kutengeneza bidhaa za mkaa thabiti kupitia mfululizo wa athari za kemikali.

- Weka malighafi kwenye chumba cha kuunguza cha tanuru ya kaboni ya mlalo.

- Anzisha vifaa vya kupokanzwa (kama vile tanuru inayowaka, tanuru ya gesi, au hita ya umeme).

- Chini ya halijoto ya juu na mazingira yasiyo na oksijeni, malighafi huanza kutekeleza mmenyuko wa kaboni.

- Kiasi kikubwa cha moshi na vitu vyenye tete vitatolewa wakati wa mchakato wa malipo. Tanuru ya mkaa ya mlalo ina mfumo wa kutoa gesi ambayo hukusanya na kutibu gesi ya kutolea nje inayozalishwa.

- Mashine ya kutengenezea mkaa ya mbao ina mfumo wa kudhibiti otomatiki wa kufuatilia na kudhibiti halijoto, shinikizo, na utoaji wa moshi wakati wa mchakato wa kuchaji.

- Tanuru ya kaboni ya usawa ina vifaa vya kutokwa kwa slag, ambayo hukusanya majivu na lami.

- Ondoa mkaa uliomalizika baada ya kukamilisha mchakato wa kaboni.

Maelezo ya kiufundi juu ya tanuru ya kuchoma mkaa

| Mfano | Uwezo kwa tanuru | Dimension | Uzito |

| 1300 | 900-1200kg/12-14H | 3*1.7*2.2M | 2500kg |

| 1500 | 1500-2000kg/12-14H | 4.5*1.9*2.3M | 4000kg |

| 1900 | 2500-3000kg/12-14H | 5*2.3*2.5M | 5500kg |

Tabia za tanuru ya moto ya usawa

- Kiasi kikubwa cha mashine kuu, kiwango cha juu cha chari, uwezo mkubwa wa uzalishaji, tani 3-10 za chari kwa saa.

- Hutumika kwa aina nyingi za malighafi: Mashine za kutengeneza mkaa bonge zinaweza kushughulikia aina nyingi za malighafi, zikiwemo mbao, mianzi, maganda ya matunda, taka za kilimo, na kadhalika.

- Gharama ya chini na vitendo vya juu vinakidhi mahitaji ya uwekezaji ya wajasiriamali wa awali.

- Mashine ya tanuru ya donge ya mkaa imeundwa kwa chuma cha pua maalum kinachostahimili joto la juu, ambacho ni dhabiti na kinachodumu, kisicho na ulemavu, chenye utendaji mzuri wa kuhifadhi joto.

Usafirishaji wa tanuru ya kaboni ya logi iliyo mlalo

Tanuri ya kuchoma kaboni ya Shuliy imeuza kwa nchi nyingi, kama vile Ecuador, Tunisia, Indonesia, Kenya, Italia, Lebanon, Uganda, na kadhalika. Hii hapa picha ya upakiaji na usafirishaji wa mashine:

Kiwanda chetu pia huzalisha tanuri za kuchoma kaboni zinazoendelea. Ikiwa una nia ya mashine zetu, jisikie huru kuwasiliana nasi na tutakupa maelezo zaidi na nukuu za mashine.

Mashine ya Briquette ya Mkaa kwa Mstari wa Uzalishaji wa Mafuta

Mashine ya briquette ya mkaa imeundwa kubana makaa au…

Mashine ya Kutengeneza Mkaa ya Shisha ya Chuma cha Pua kwa Vidonge vya Briquette za Hookah

Vidonge vya mkaa za hookah zinazotengenezwa na mashine ya shisha ya chuma cha pua ya majimaji…

Mashine ya Kutengeneza Mkaa ya Shisha ya Rotary kwa Briquettes za Hookah

Mashine ya kuunda mkaa wa shisha ya mzunguko ni kiotomatiki, yenye bonyeza mara mbili…

Mashine ya Press ya Mpira wa Mkaa kwa Sekta ya BBQ

Mashine za kusindika mipira ya mkaa zimetengenezwa kubana nyenzo zisizofungwa…

Mashine ya Makaa ya Nyuki kwa Mstari wa Uzalishaji wa Briquette

Mashine ya mkaa ya honeycomb ni kuchukulia mkaa uliosindikwa vizuri…

Tanuru ya Kaboni ya Hoist ya Wima kwa Kiwanda cha Kutengeneza Mkaa

Tanuru ya ukarbonishaji ya kuinua hutumika kuchoma kuni au…

Tanuru ya Kaboni ya Kuendelea kwa Kutengeneza Mkaa wa Kichwa cha Mpunga

Tanuru ya ukarbonishaji ya mkaa inayendelea ni kifaa bora kwa ajili ya kukausha…

Mashine ya Briquette ya Sawdust kwa Mstari wa Usindikaji wa Mkaa wa Biomasi

Mashine ya briquette ya unga wa mbao imeundwa kubana vifaa vya taka…

Mashine ya Kufunga Mkaa ya BBQ katika Mstari wa Uzalishaji wa Briquette

Mashine ya kufunga mkaa wa BBQ ni kifaa kilichobobea katika…

Mashine ya Kufunga Mkaa ya Shisha ya Kazi nyingi Inauzwa

Inom kolbearbetningsindustrin, förpackningsmaskinen för vattenpipa kol...

Bidhaa Moto

Tanuru ya Kaboni ya Kuendelea kwa Kutengeneza Mkaa wa Kichwa cha Mpunga

Kontinuerlig trähärdning sågfurna är en ideal utrustning…

Mashine ya Kukuza ya Otomatiki kwa Kiwanda cha Recyle ya Mbao

Mashine ya kusaga hukata magogo makubwa kwenye...

Kichomeko Kikubwa cha Mill Crusher katika Kiwanda cha Kutengeneza Mkaa wa Mbao

Mashine crusher ya mtambo wa nyundo kwa kuni inafanya kazi kwa kutumia…

Mashine ya Kizuizi cha Pallet kwa Kiwanda cha Uzalishaji wa Ufungashaji wa Mbao

Saizi za kawaida za vipande vya mbao ambazo zinaweza…

Kiwanda cha Kunyanyua Mbao Kiotomatiki kwa Mauzo

Mashine ya kubana mbao huchakata mbao zilizoshinikizwa...

Kiwanda cha Kukata Kiwango Kikubwa cha Mashine ya Kukata Mbao

Chomaji kamili imeundwa kuvunja…

Mashine ya Briquette ya Sawdust kwa Mstari wa Usindikaji wa Mkaa wa Biomasi

Mashine ya kutengenezea mkaa wa majani inaweza kutoa nje na kuunda...

Mashine ya Kikavu ya Drum ya Rotary kwa Kiwanda cha Kukausha Poda ya Sawdust

Mashine ya kukausha ngoma inayozunguka ni mashine ya kiwanda inayotumika sana…

Mashine ya Briquette ya Mkaa kwa Mstari wa Uzalishaji wa Mafuta

Mashine ya briquette za makaa, pia inajulikana kama briquette…