Гидравлическая машина для производства древесного угля для кальяна для формирования угля

Машина для прессования угля для кальяна | Машина для производства угольных брикетов для кальяна

Гидравлическая машина для производства древесного угля для кальяна для формирования угля

Машина для прессования угля для кальяна | Машина для производства угольных брикетов для кальяна

Обзор функций

Гидравлическая машина для производства древесного угля для кальяна использует гидравлическую технологию для сжатия и формования предварительно обработанного сырья в твердые однородные брикеты древесного угля для кальяна.

Требования к сырью, используемому при водокопчении, достаточно строгие. Чтобы гарантировать качество конечного продукта, обычно используемое сырье включает, среди прочего, порошок бамбукового угля, порошок фруктового угля и порошок древесного угля из скорлупы кокосового ореха.

Готовый кальянный уголь, полученный на этом аппарате, отличается высокой плотностью, идеальной формой и привлекательным внешним видом. Кроме того, он легко горит, не имеет запаха и обеспечивает длительное время горения. С помощью настраиваемых форм клиенты могут создавать хлопья древесного угля различной формы в соответствии со своими предпочтениями.

С высокой давлением и высокой плотностью формования, машина может прессовать и формовать за одну секунду. Наша гидравлическая машина для брикетирования угля для кальяна проста в эксплуатации и обладает отличными характеристиками, что поддерживается и любится многими клиентами. Она похожа по функциям на машину для изготовления угля для кальяна из нержавеющей стали. Наша гидравлическая пресс-машина для угля для кальяна имеет разные модели и стили.

Сырье для гидравлического угольного пресса

Сырье может включать древесный уголь, каменный уголь, кокс и подобные вещества. Альтернативно, они могут состоять из богатой лигнином биомассы, такой как скорлупа кокосовых орехов, бамбук, рисовая шелуха и опилки. Полученный древесный уголь можно использовать для приготовления барбекю или в качестве топлива для курения.

Гидравлическая машина для приготовления угля для кальяна готовая продукция

Наша машина для производства древесного угля для кальяна может производить угольные брикеты различной формы, включая квадратную, круглую, кольцевую, ромбовидную, треугольную, цилиндрическую и т. д. Среди наиболее распространенных размеров:

- Квадратная форма: 20*20*20 мм, 25*25*25 мм.

- Круглая форма: диаметр 30 мм, 33 мм, 34 мм, 35 мм, 40 мм.

Основная конструкция гидравлической машины для приготовления древесного угля для кальяна

Гидравлическая машина для производства древесного угля для кальяна обычно включает в себя несколько ключевых компонентов: гидравлический цилиндр, гидравлический насос, гидравлический клапан, сальник, форму для брикетов и систему управления.

Гидроцилиндр служит основным элементом, использующим давление гидравлического насоса для приведения в движение поршня и создания силы. Между тем, сальник и форма для брикетов необходимы для выдерживания давления и формирования древесноугольных брикетов.

Пресс-форма для прессования древесного угля

Формы для этой гидравлической машины для производства древесного угля для кальяна обычно бывают квадратной и круглой формы. Тем не менее, мы также предлагаем варианты настройки форм различных форм, рисунков, логотипов и размеров в соответствии с вашими конкретными требованиями.

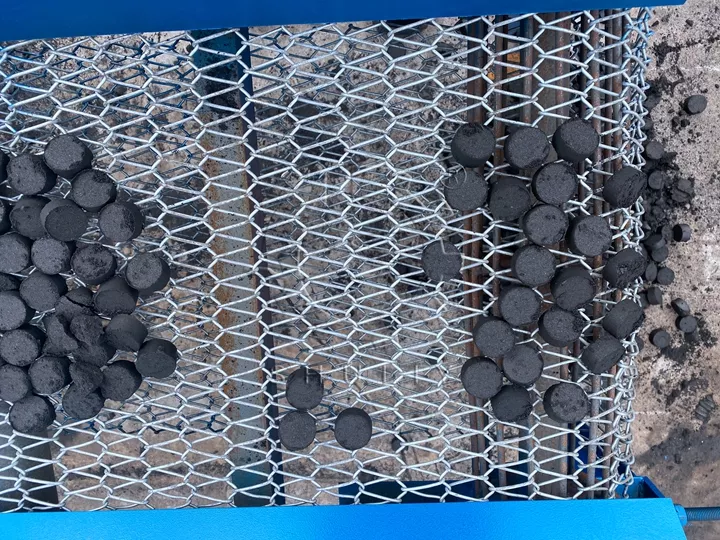

Особенность транспортировочного пояса гидравлической пресс-машины для угля

Гидравлическая машина для производства древесного угля для кальяна поставляется с транспортировочной лентой, которая может быть сетчатой или плоской. Сетчатый ремень эффективно пропускает излишки угольной пыли.

Параметры гидравлической машины для формования древесного угля для кальяна

Технические параметры гидравлических машин для угля для кальяна могут различаться в зависимости от модели и требований к дизайну. Ниже приведены некоторые общие технические параметры модели SL-HS-2 , которые могут быть доступны для гидравлических машин для угля для кальяна. Для получения информации о других моделях машин, пожалуйста, свяжитесь с нами.

Модель: SL-HS-2

- Давление: 80 тонн

- Масса: 2800 кг

- Мощность гидравлического насоса: 18,5 кВт

- Основное измерение хоста: 1000*2100*2000 мм

- Мощность подачи: 0,75 кВт

- Мощность разряда: 0,75 кВт

- Разгрузочный конвейер: 800*850*1850 мм

- Размер шкафа управления: 530*900*1100 мм

- Емкость:

- 42 штуки за раз, 3 раза в минуту (круглая форма)

- 44 штуки за раз, 3 раза в минуту (кубическая форма)

Как работает гидравлическая машина для формования угля для кальяна?

Подготовка сырья

Во-первых, необходимо подготовить сырье, используемое для приготовления древесного угля для кальяна. Обычно это древесная щепа, бамбуковая щепа или другое волокнистое сырье, которое было смешано, измельчено и обработано; Также можно добавить специи, зелень и т. д.

Смешивание связующего

Сырье смешивается со связующим, которым может быть растительная камедь, крахмал и т. д., что обеспечивает необходимую для формования силу связывания.

Работа гидравлической системы

Гидравлическая машина для производства древесного угля для кальяна имеет внутреннюю гидравлическую систему, которая состоит из гидравлического бака, гидравлического насоса, гидравлического цилиндра и других компонентов. Гидравлическая система подает жидкость под высоким давлением (обычно гидравлическое масло), которая подается в гидравлический цилиндр через гидравлический насос.

Компрессионное формование

Когда жидкость попадает в гидроцилиндр, цилиндр находится под давлением жидкости, что создает силу. Эта сила передается на сырье в формовочной камере через плунжер или поршень, сжимающий сырье в определенную форму древесноугольного брикета.

Сбросьте давление

Как только угольные брикеты сформированы и гидравлическая система перестает подавать жидкость, давление в гидроцилиндре снижается, сбрасывая давление на угольные брикеты.

Сушка и упаковка

Угольные брикеты необходимо сушить, чтобы удалить из них влагу, повысить теплотворную способность и улучшить стабильность. Кроме того, его можно обрабатывать для придания вкуса и т. д. по мере необходимости.

Гидравлическая система гарантирует, что угольные брикеты остаются однородными и стабильными, обеспечивая курильщику кальяна превосходный дым и общее удовольствие от курения.

Особенности гидравлической машины для приготовления угля для кальяна

- Эта машина оснащена гидравлическим насосом высокого давления, что значительно повышает плотность продукта. Полученные древесноугольные брикеты прочны и устойчивы к поломке во время использования.

- Клиенты имеют возможность регулировать давление формования и плотность кальян кусочки древесного угля для удовлетворения их конкретных потребностей.

- Формы отличаются высоким качеством и точностью, что позволяет производить брикеты идеальной формы и гладкой поверхности.

- Благодаря гидравлическому клапану и системе управления он позволяет точно управлять давлением, скоростью потока и временем прессования.

- В системе используется управление ПЛК, а сенсорный экран шкафа отображает рабочее состояние, что делает ее удобной для быстрой настройки параметров и обеспечивает полностью автоматическую работу.

- Весь блок изготовлен из нержавеющей стали, что обеспечивает надежность и долговечность.

Как показано на видео выше, наша фабрика производит различные машины для приготовления угля для кальяна. Вы можете выбрать машину, которая лучше всего соответствует вашим потребностям, исходя из вашего сценария использования, масштаба обработки, метода производства и т. д. Не стесняйтесь обращаться к нам в любое время.

Нержавеющая сталь машина для изготовления кальяна из угля для таблеток кальяна

Таблетки для кальянного угля, произведённые гидравлической шишей из нержавеющей стали…

Ротационный аппарат для изготовления кальяна из угля для кальянных

Роторная машина для изготовления угля для кальяна — автоматическая, с двойным прессованием…

Многофункциональный упаковочный аппарат для угля для кальяна на продажу

В индустрии переработки угля упаковочная машина для кальянного угля…

Линия производства угля для кальяна, машины для изготовления брикетов для кальяна

Линия по производству угля для кальяна превращает сырьё в высококачественный…

2 машины для прессования таблеток угля для кальяна экспортированы в Алжир

Недавно лофт-бар кальяна из Алжира решил приобрести…

Иорданский клиент представляет высокоскоростную ротационную машину для изготовления угля для кальяна

Недавно наша компания завершила производство угля для кальяна…

Доставка машины для прессования таблеток угля для кальяна в Марокко прошла гладко

Хорошие новости! Группа Shuliy успешно отправила 2 комплекта…

Португальский клиент приобрел оборудование для производства кальяна из угля

В последние годы Португалия активно продвигала экологически чистые и возобновляемые…

Машина для производства брикетов из древесного угля для линии производства топлива

Машина для производства угольных брикетов предназначена для прессования угля или…

Пресс для угольных шариков для индустрии барбекю

Машины для прессования угольных шариков разработаны для сжатия рыхлого…

Горячий продукт

Мельница для кормовых гранул для животных

Гранулятор для корма используется для производства кормовых гранул для животных…

Клетчатая машина для формирования брикетов из угля

Углеродная машина-«сотовый» уголь рассматривает хорошо обработанный угольный пыль как…

Машина для производства брикетов из древесного угля для линии производства топлива

Машина для брикетирования угля, также известная как брикетировочная…

Доска для сушки угля на конвейере

Ленточная сушилка для древесноугольных брикетов представляет собой…

Непрерывная коксующая печь для производства угля из рисовой шелухи

Непрерывная печь для карбонизации угля — идеальное оборудование…

Машина для гранулирования древесного угля для завода по формовке брикетов

Угольный измельчитель имеет функции дробления,…

Машина для изготовления паллетных блоков для производства деревянной упаковки

Стандартные размеры деревянных брусков, которые могут…

Пресс для угольных шариков для индустрии барбекю

Шариковый пресс для древесного угля эффективен и удобен…

Машина для строгания древесины для животного bedding

Станок для стружки древесины предназначен для обработки…