Machine de broyeur de bois pour fabriquer de la sciure de bois

Broyeur de bois | Broyeur de bois

Machine de broyeur de bois pour fabriquer de la sciure de bois

Broyeur de bois | Broyeur de bois

Aperçu des fonctionnalités

Le broyeur à bois est doté de couteaux rotatifs à grande vitesse et d'un rotor, lui permettant de broyer efficacement divers types de matériaux en bois, notamment des branches, des racines et des déchets de feuilles, en copeaux de bois, copeaux et sciure de bois d'une taille de 3 à 20 mm.

De plus, cette machine peut traiter du bois d'un diamètre compris entre 1 et 45 cm, ainsi qu'une gamme de matières premières comme le bambou, les tiges de maïs, les tiges de sorgho, les épis de maïs, le bois d'œuvre, le bois non traité, les palettes, les portes, les lattes et les cadres.

Avec cette opération, il est possible de réduire le volume des déchets de bois. Avec sa structure compacte et sa conception simple, la machine fonctionne avec peu de bruit et est facile à nettoyer et à entretenir.

Il est particulièrement adapté au traitement des déchets de bois, à la fabrication de panneaux artificiels, aux usines de papier et à de nombreuses autres applications, ce qui en fait un choix idéal pour la production de divers produits ligneux et de combustibles issus de la biomasse.

Avantages de la machine de broyage de bois

- Le rendement peut atteindre jusqu'à 600-4 000 kg/h, améliorant l'efficacité du concassage de plus de 50% par rapport aux modèles traditionnels.

- Il est doté d'un concassage à moteur unique, qui permet d'économiser de l'énergie et de réduire les coûts, permettant ainsi des économies d'électricité pour le 40% au même niveau de sortie.

- La capacité de concassage fin garantit que la taille de sortie du 85% est inférieure à 3 mm, avec un taux de concassage supérieur à 90%.

- De plus, le capot arrière du cadre supérieur peut être ouvert manuellement, ce qui rend la maintenance beaucoup plus pratique.

Applications larges du broyeur de bois

Un broyeur de bois est une machine cruciale dans la production de charbon de bois. Il traite les branches de bois, le bambou, la paille, les tiges de maïs et de sorgo, la paille de blé et d'autres types de bois en sciure de bois de moins de 5 mm, ce qui est nécessaire pour la fabrication de briquettes de sciure. (En savoir plus : Machine à Briquettes de Sciure pour Ligne de Traitement de Charbon de Biomasse >>)

De plus, la sciure de bois a diverses applications, notamment la production de papier, la fabrication de panneaux haute densité (HDB), la création de panneaux de fibres, la production de briquettes de biomasse, le combustible de chaudière, la production de granulés de bois et même la culture de champignons comestibles. Les copeaux de bois peuvent également être utilisés pour produire des panneaux de particules et servir de litière pour les animaux.

Structure principale de la machine de pulvérisation de bois

Il contient généralement un port d'alimentation (qui peut être personnalisé en fonction de différents matériaux), un corps de machine (boîtier), une chambre de concassage, un disque de coupe, des lames, un tamis (avec taille réglable des trous de tamis), un port de décharge et d'autres pièces.

Selon vos besoins, la machine peut également être équipée d'un convoyeur.

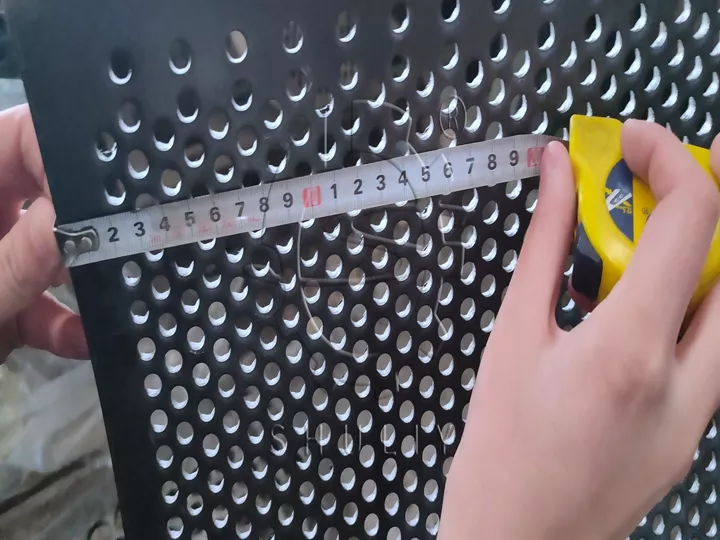

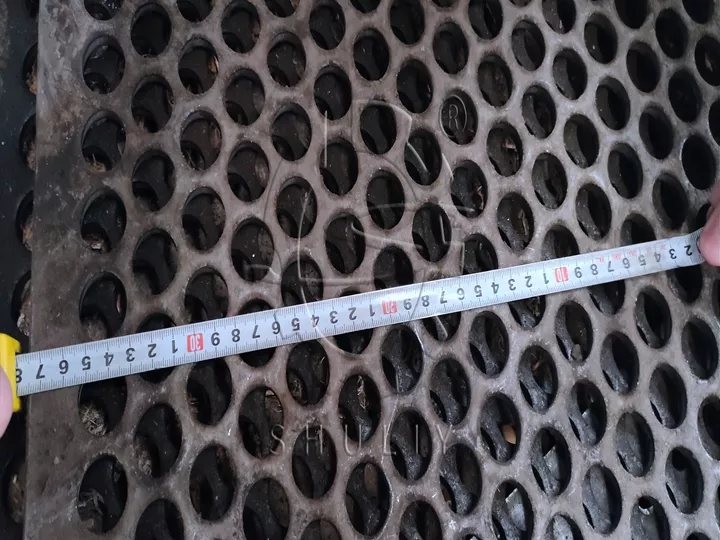

Tamis de machine de broyeur de bois

Notre broyeur à bois est équipé de tamis de différentes tailles de mailles, permettant la production de particules de sciure de finesse variable. Vous pouvez choisir la taille de maille appropriée du tamis en fonction de leurs besoins (3-20 mm).

Broyeur de bois mobile

Nous pouvons ajouter des roues au bas de la machine afin que vous puissiez passer à différents scénarios.

Accessoires de déchiqueteuse à bois

Les principaux accessoires de la machine comprennent des lames, des disques de coupe, des lames de marteau et des tamis. Les lames sont en alliage pour plus de durabilité et de netteté. Les marteaux sont traités thermiquement et cémentés. Les lames de marteau et les lames de coupe sont des pièces consommables que vous pouvez également acheter en fonction de leurs besoins.

Comment faire fonctionner cette broyeuse de bois ?

La déchiqueteuse à bois électrique se compose généralement d’une ou plusieurs lames ou marteaux rotatifs, qui déchirent, écrasent et brisent les matières premières.

Lorsque la machine fonctionne, le moteur entraîne la poulie à fonctionner à grande vitesse. Ensuite, le disque de coupe à l'intérieur du boîtier de la machine est entraîné, tirant les lames sur sa face supérieure pour fonctionner à une vitesse rapide.

La lame, combinée à un flux d'air à grande vitesse, coupe efficacement le bois en copeaux et copeaux. Pendant ce temps, le marteau tourne rapidement pour briser les plus gros copeaux de bois en fine sciure de bois.

Une fois le matériau broyé, tout ce qui est plus petit que le diamètre du tamis est expulsé par les trous du tamis, tandis que les morceaux plus gros restent dans la chambre de concassage pour être traités ultérieurement par la lame et le rotor.

Approvisionnement :

- transformation et recyclage du bois

Outils :

- broyeur de bois

Matériaux : bois de récupération

Options d'alimentation pour la machine de fabrication de sciure de bois

La machine de broyage de bois peut être alimentée par des moteurs électriques, des moteurs diesel ou des groupes moteurs diesel. Vous pouvez sélectionner l'option d'alimentation qui correspond le mieux à vos besoins. De plus, nous vous proposerons l’option d’alimentation la plus adaptée en fonction de vos besoins spécifiques.

Paramètres techniques de la meuleuse à bois

| Modèle | Capacité | Taille de sortie | Pouvoir |

| SL-420 | 600-800 KG/H | 0,3-0,8 cm | 7,5-11 kW |

| SL-500 | 1000-1500KG/H | 0,3-0,8 cm | 18,5 kW |

| SL-600 | 1500-2000 KG/H | 0,3-0,8 cm | 30kw |

| SL-700 | 2000-2500 KG/H | 0,3-0,8 cm | 37kw |

| SL-900 | 2500-3000 KG/H | 0,3-0,8 cm | 55kw |

| SL-1000 | 3000-4000KG/H | 0,3-0,8 cm | 75+7,5kw |

La machine à broyer le bois est essentielle pour le traitement et le recyclage des déchets de bois. Elle gère efficacement différents types et tailles de bois, contribuant à la réduction du gaspillage de bois. Avec ses nombreuses applications et ses caractéristiques écologiques, la fabrication de sciure est devenue de plus en plus populaire tant dans le secteur du traitement du bois que dans le secteur environnemental. Si vous avez des besoins, n'hésitez pas à nous contacter.

Machine à briquettes de sciure pour la ligne de traitement du charbon de biomasse

La machine à briquettes de sciure de bois est conçue pour comprimer les déchets…

Machine de séchage à tambour rotatif pour l'usine de séchage de poudre de sciure

La machine de séchage à tambour rotatif est couramment utilisée pour évaporer…

Machine à scier automatique pour l'usine de recyclage du bois

La scierie utilise soit une scie circulaire, soit une scie à bande…

Machine à décapeur de bois pour écorçage de troncs

L'écorceuse de bois, équipée de lames en alliage à haute résistance et de technologies avancées…

Concasseur à marteaux de grande capacité dans l'usine de fabrication de sciure

Le broyeur à marteaux en bois fonctionne en utilisant la vitesse élevée…

Machine à copeaux de bois pour litière animale

La machine à raser le bois est conçue pour transformer le bois de…

Machine à déchiqueter le bois pour l'usine de fabrication de sciure

La déchiqueteuse à bois est conçue pour briser le bois,…

Machine de broyage à grande capacité pour le broyage de bois

Le concasseur complet est conçu pour briser les gros morceaux…

Machine à pellets pour alimentation animale

La machine de broyage de granulés alimentaires est une sorte d'équipement…

Machine automatique de presse à palettes en bois à vendre

La presse à palettes en bois est notre produit phare, principalement…

Produit chaud

Machine à décapeur de bois pour écorçage de troncs

Équipé de lames en alliage à haute résistance et d'un système rotatif avancé…

Machine en acier inoxydable pour la fabrication de charbon de narguilé pour les tablettes de briquettes

La machine à fabriquer du charbon de chicha est également un…

Four de carbonisation continu pour la fabrication de charbon de coque de riz

Le four de carbonisation continue du charbon de bois est un équipement idéal…

Machine de broyage à grande capacité pour le broyage de bois

Le concasseur complet est conçu pour décomposer…

Machine à briquettes de charbon pour la ligne de production de carburant

Machine à briquettes de charbon de bois, également connue sous le nom de briquette…

Machine multifonctionnelle d'emballage de charbon de narguilé pour la vente

La machine d'emballage de charbon de narguilé est un équipement spécial…

Four de carbonisation vertical à levage pour l'usine de fabrication de charbon

Le four à charbon de bois est utilisé pour carboniser…

Machine à pellets pour alimentation animale

Le moulin à granulés alimentaires est utilisé pour fabriquer des animaux…

Machine de séchage à tambour rotatif pour l'usine de séchage de poudre de sciure

La sécheuse à tambour rotatif est une machine industrielle courante…