Barbekü Endüstrisi İçin Kömür Topu Pres Makinası

Barbekü kömür makinesi | Kömür briket makinesi

Barbekü Endüstrisi İçin Kömür Topu Pres Makinası

Barbekü kömür makinesi | Kömür briket makinesi

Bir Bakışta Özellikler

Kömür topu pres makineleri, gevşek kömür, kömür tozu, mineral tozu ve diğer çeşitli tozları düzenli, yoğun küresel, oval, oval, yumurta şeklinde ve yastık şeklinde briketler halinde sıkıştırmak için tasarlanmıştır. Bu makineler refrakterlerde, enerji santrallerinde, metalurjide, kimya endüstrisinde, enerjide, ulaşımda, yakıt işlemede, ısıtmada ve diğer endüstrilerde geniş uygulama alanları bulmaktadır.

Hidrolik ve silindir basıncı yoluyla 98% veya daha yüksek bir kalıplama hızı elde etme yeteneği sayesinde, ortaya çıkan kalıplanmış parçacıklar yalnızca yoğun olmakla kalmaz, aynı zamanda düzenli bir görünüme de sahip olur, bu da onların taşınmasını ve depolanmasını kolaylaştırır.

Müşterilerimiz genellikle bu makineyi satılık barbekü kömürü topları yapmak için satın alırlar. Farklı çıktı gereksinimlerini karşılamak için farklı modellerimiz var. Bilyalı presin ruloları değiştirilerek farklı şekil ve boyutlarda briketler üretilebilmektedir.

Kömür topu pres makinesi tarafından işlenen hammaddeler

Kömür topu pres makinesi, kömür tozu, kömür tozu, çeşitli metalurjik fırın kuru tozları, metal magnezyum kuru tozu, beyaz kireç kuru tozu, demir tozu, koklaşabilir taş kömürü, alüminyum, demir, kalay oksit dahil olmak üzere çeşitli toz halindeki malzemeleri işleme kapasitesine sahiptir. , karbon tozu, cüruf, alçı taşı, atık, çamur, kaolin, aktif karbon ve diğer birçok toz halindeki madde türü.

Ayrıca farklı türdeki hayvan yemlerini, gübreleri, atık malzemeleri ve kalıntıları da işleyebilir. Ham kömür için önerilen nem seviyesi yaklaşık 30%'dir ve boyutu 5 mm'nin altında olmalıdır. Briket oluşturmak için parça kömür veya hindistan cevizi kömürü kullanıyorsanız, bunu bir kömür kırma makinesi kullanarak toz haline getirmeniz gerekir.

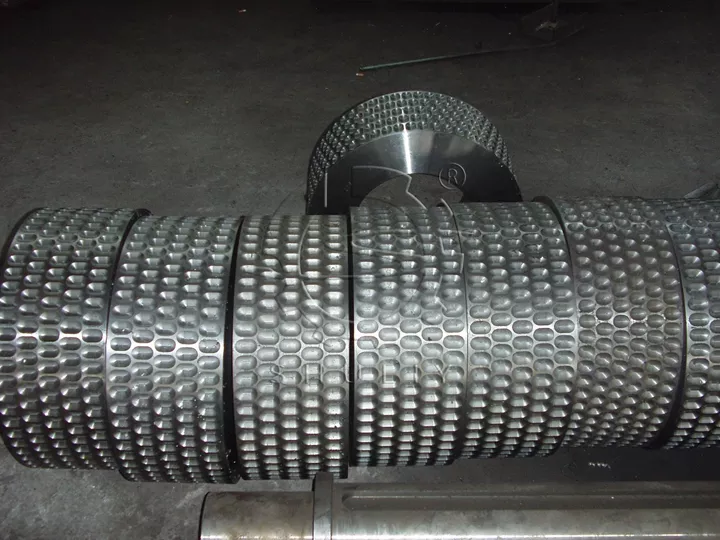

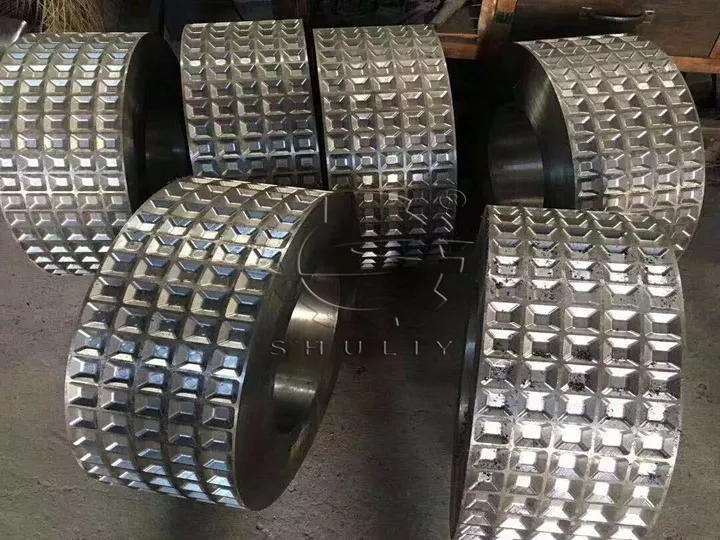

Çeşitli kömür topu presleri için özelleştirilebilir kalıplar

Basınç silindiri, kömür topu pres makinesinin çok önemli bir parçasıdır ve genellikle makine içinde çiftler halinde bulunur. Kömür tozu ve partiküllerinin yüksek basıncı ve sürtünmesi nedeniyle aynı zamanda hassas bir bileşendir. Bu nedenle düzenli olarak değiştirilmesi gerekir.

Sertliklerini ve aşınmaya karşı dirençlerini artırmak için tüm silindirlerin ısıl işleme tabi tutulmasını sağlıyoruz. Ek olarak, silindirleri müşterilerimizin özel şekil ve boyut gereksinimlerini karşılayacak şekilde özelleştirebiliriz.

Barbekü kömürü makinesi bitmiş ürünler

Bitmiş kömür topu briketleri çeşitli endüstrilerde kullanılabilir. Bunlar yastık şekilleri, oval küreler, yumurta şekilleri, baklava şekilleri, monogramlar, kalp yıldızı şekilleri vb. olabilir.

Barbekü kömürü yapma makinesi teknik parametreleri

Shuliy, kömür topu pres makinelerinin birkaç farklı modelini üretiyor; iş verilerine göre, küçük ve orta ölçekli modeller daha popüler ve aşağıdaki dört model daha fazla satıyor.

| Modeli | 290 | 360 | 400 | 500 |

| Kapasite(ton/saat) | 2-3 | 4 | 6 | 10 |

| Toz (kw) | 5.5-7.5 | 7.5 | 11-15 | 18.5-22 |

| Rulo malzemesi | 65 milyon | 65 milyon | 65 milyon | 65 milyon |

| Bitmiş ürünlerin çapı (mm) | 30-60 | 30-60 | 30-60 | 30-60 |

Barbekü kömürü briket yapma tesisinin iş akışı

Hammadde işleme

Öncelikle hammaddelerin kırma, eleme veya karıştırma gibi ön işlemlere tabi tutulması gerekir. Hammaddelerin parçacık boyutunun ve neminin bilyalı presin gereksinimlerini karşıladığından emin olun.

Bağlayıcı ekleme

Topun sıkılığını arttırmak için bazen ham maddeye bir bağlayıcı eklemek gerekebilir. Bu bağlayıcılar nişasta, bal vb. gibi doğal olabileceği gibi kimyasal olarak sentezlenmiş de olabilir.

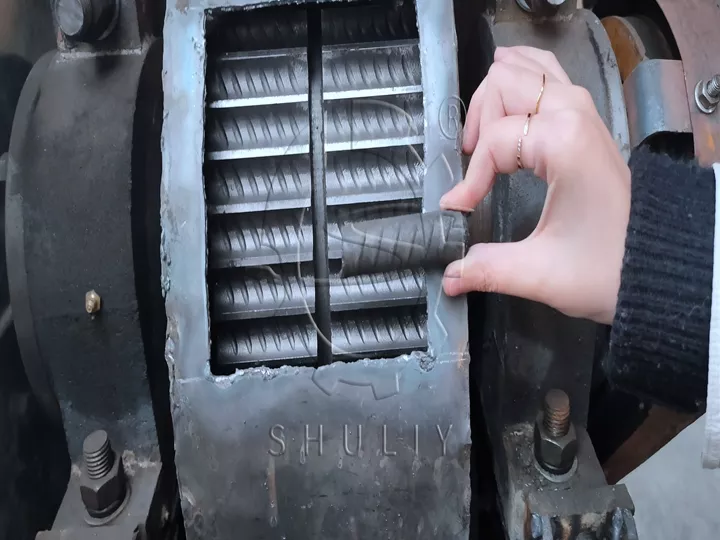

Top presleme ve kalıplama

Ön işleme tabi tutulmuş hammaddeler, kömür topu pres makinesinin besleme açıklığına konur ve silindir, hammaddeleri küresel bir şekle sıkıştırmak için belirli bir basınç uygular.

Soğutma ve paketleme

Preslenen toplar soğuduktan sonra kolay saklama ve satış için paketlenebilir.

Kömür topları presleme makinesinin çalışma prensibi

- Kömür pres makinesini çalıştırın, motor kayışı redüktöre doğru hareket ettirir ve ardından ana mili kaplin boyunca hareket ettirir.

- Bir çift açık dişli, iki silindirin senkronize çalışmasını sağlar. Aynı zamanda, malzeme depolama kutusundan kantitatif ekipmana doğru kalıplama haznesine eşit olarak aktarılır.

- Barbekü kömür topu presleme makinesinin şekillendirme işlemi sırasında basınç giderek artar ve sonunda makine silindirlerinin merkez hattında maksimum değere ulaşır.

- Daha sonra malzeme hattı geçtikten sonra kalıplama basıncı hızla düşer ve top başarıyla çıkarılır ve kalıplama tamamlanır.

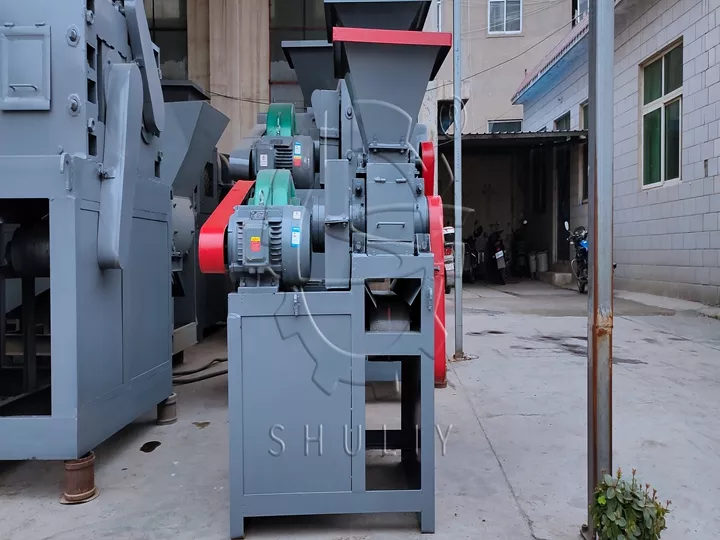

Kömür briket ekstruder yapmak için fabrika

Shuliy güçlü bir üretim kapasitesine sahiptir, stokta yeterli sayıda makinemiz ve müşterilere barbekü kömürü briketleme makinelerinin zamanında tedarikini sağlayabilecek verimli bir üretim yöntemimiz var.

Fabrikamız ayrıca nargile kömürü yapım makineleri, kömür briket ekstrüzyon makineleri gibi başka kömür kalıplama makineleri de üretmektedir.

Barbekü kömürü makinesi birçok ülkeye satıldı

Kömür üretiminde zengin deneyime sahibiz ve Peru, Tanzanya, ABD, Birleşik Arap Emirlikleri, Kenya, Güney Afrika, Filipinler, Endonezya, Zambiya, Nijerya, Hindistan, Paraguay, Malezya, Rusya, Uganda'da popüler kömür üretim ekipmanlarının üretilmesine yardımcı olduk. , Gana, Sri Lanka ve diğer ülkeler. Aşağıda bilyalı pres makinesi sevkiyatının resimleri bulunmaktadır.

Barbekü kömürü briket pres makinesinin özellikleri

- Üretim ölçeği 500 kg/saat'ten 10 t/saat'e kadar ayarlanabildiğinden hem küçük hem de büyük yatırım projeleri için idealdir.

- Basit yapısı tecrübesi az personelin kullanımına olanak sağlar.

- Makine işleyebilir barbekü çeşitli boyut ve şekillerde kömür briketleri.

- Nihai ürün, eşit yoğunluk, istikrarlı kalite ve tutarlı top boyutuna sahiptir.

- Bu kömür topu pres makinesi ulusal standartlara göre üretilmiştir ve uzun bir servis ömrüne sahiptir.

Shuliy Machinery, biyokütle kömür üretimi için dünya çapındaki müşterilere danışmanlık ve tasarımdan planlama, üretim, kurulum ve gelecekteki yükseltmelere kadar her şeyi kapsayan kapsamlı bir çözüm sunuyor. Özel ihtiyaçlarınıza ve koşullarınıza göre uyarlanmış en yüksek kalitede çözümleri sunmaya kararlıyız. Bize ulaşmaktan çekinmeyin!

Kömür Kömürü Makinesi Yakıt Üretim Hattı İçin

Kömür briquet makinesi kömürü veya … sıkıştırmak için tasarlanmıştır

Paslanmaz Çelik Şişa Kömürü Yapım Makinesi Hookah Kömürü Tabletleri İçin

Paslanmaz çelik hidrolik şişe nargile kömürü tabletleri ile üretilir…

Döner Şişa Kömürü Yapma Makinesi Hookah Kömürü İçin

Rotasyonel şişe nargile kömürü yapma makinesi otomatik, çift baskılı…

Petek Kömür Makinesi Briket Oluşturma Üretim Hattı İçin

Balık ağacı kömür makinesi iyi işlenmiş kömürü dikkate alır…

Dikey Kızaklı Kızıltaş Fırını Kömür Üretim Tesisi İçin

Vinçli karbonizasyon fırını ağaçları kömürleştirmek için kullanılır…

Küçük Kömür İşleme İçin Yatay Kızıltaş Fırını

Yatay karbonizasyon fırını, kurutma için bir ekipman türüdür...

Pirincin Külünden Kömür Yapımı İçin Sürekli Kızıltaş Fırını

Sürekli kömür karbonizasyon fırını kuru için ideal bir ekipmandır…

Odun Tozu Kömür Makinesi Biyokütle Kömürü İşleme Hattı İçin

Talaş briket makinesi, atık malzemeleri sıkıştırmak için tasarlanmıştır…

Barbekü Kömürü Paketleme Makinesi Kömür Presleme Hattında

Barbekü kömürü paketleme makinesi,… konusunda uzmanlaşmış bir cihazdır…

Çok Fonksiyonlu Şişa Nargile Kömürü Paketleme Makinesi Satışta

Kömür işleme endüstrisinde, nargile kömürü paketleme makinesi…

Sıcak Ürün

Çok Fonksiyonlu Şişa Nargile Kömürü Paketleme Makinesi Satışta

Nargile kömürü paketleme makinesi özel bir ekipmandır…

Otomatik Kestane Makinesi Ahşap Geri Dönüşüm Tesisi İçin

Testere değirmeni makinesi daha büyük kütükleri keser…

Odun Tozu Kömür Makinesi Biyokütle Kömürü İşleme Hattı İçin

Biyokütle kömür yapma makinesi ekstrüzyon yapabilir ve şekillendirebilir…

Otomatik Ahşap Palet Pres Makinesi Satılık

Ahşap palet pres makinesi esas olarak sıkıştırılmış ahşapları işler…

Kömür Öğütme Makinesi Briquet Şekillendirme Tesisi İçin

Kömür öğütme makinesi kırma, … işlevlerine sahiptir

Ahşap Ambalaj Üretim Tesisi İçin Palet Blok Makinesi

Parçalanabilecek odun bloklarının standart boyutları şunlardır…

Talaş Üretim Tesisi İçin Büyük Çekiçli Değirmen Kırıcı

Odun kırıcı değirmenin çalışması…

Kapsamlı Kırıcı Büyük Kapasiteli Ahşap Parçalayıcı Makinesi

Kapsamlı kırıcı, parçalamak için tasarlanmıştır…

Petek Nargile Kömürü Üretimi İçin Briquette Kömür Kurutucu

Briket kömürü kurutucusu buharlaşmayı ifade eder…