Машина для производства древесного угля для кальяна из нержавеющей стали для таблеток для кальяна

Машина для прессования угля для кальяна | Машина для производства древесного угля для кальяна

Машина для производства древесного угля для кальяна из нержавеющей стали для таблеток для кальяна

Машина для прессования угля для кальяна | Машина для производства древесного угля для кальяна

Обзор функций

Таблетки угля для кальяна, производимые гидравлическими машинами для производства древесного угля из нержавеющей стали, известны своим быстрым воспламенением, длительным временем горения, отсутствием дыма, токсичности или раздражающих запахов, что делает их популярным экологически чистым выбором.

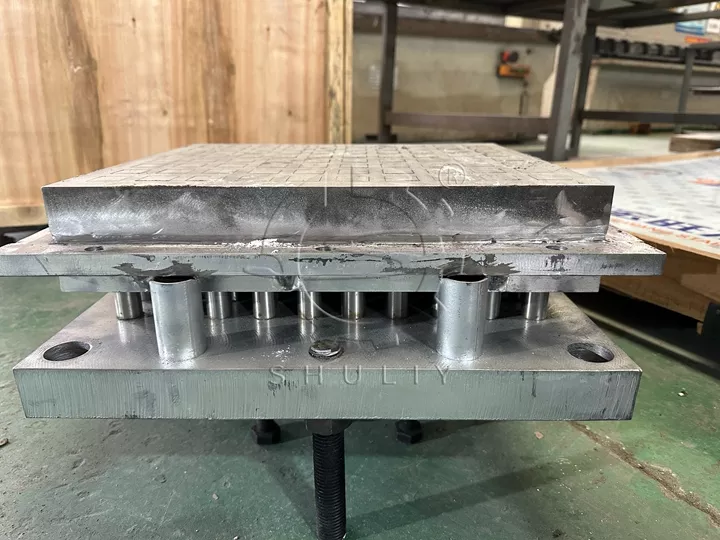

Плотность и твердость угольных шариков можно регулировать, изменяя настройки давления и времени. Формы могут быть адаптированы в соответствии с требованиями заказчика, что позволяет производить уголь для кальяна различной формы, включая круглую, квадратную, выпукло-вогнутую, прямоугольную и треугольную.

Изготовленная из нержавеющей стали, машина не только устойчива к коррозии и легко чистится, но также сводит к минимуму потери тепла и защищает работников от ожогов. Он находит широкое применение в развлечениях и релаксации, промышленной плавке, ежедневном отоплении, приготовлении пищи и даже в медицинских целях.

Сырье, обрабатываемое гидравлической машиной для приготовления древесного угля для кальяна

Лучшим и наиболее часто используемым сырьем для изготовления угольных брикетов для кальяна является порошок древесного угля из скорлупы кокосового ореха. Помимо этого используется натуральная древесина, такая как дуб, тик, яблоня и вишня.

Угольной древесной пыли обычно обладают хорошей горючестью и долгим временем обгорания. Смесь древесной угольной пыли. Все эти исходные материалы сначала обугливаются, что можно постоянной углеобжигающей печи, затем перерабатываются в порошок в grinder. Чем тоньше порошок, тем более гладким и лучшим внешним видом будет готовый продукт.

Каково применение угля для кальяна?

Кальянный уголь – это табачное изделие, используемое при курении кальяна. Уголь для кальяна впервые появился на Ближнем Востоке, где развилась давняя культура и традиция курения кальяна.

Курение кальяна рассматривается как способ общения, развлечения и отдыха, и люди часто используют уголь для кальяна дома, в кафе или в общественных местах. Кальянный уголь можно комбинировать с различными табачными ароматизаторами и специями для получения разнообразных ароматизированных кальянов.

Готовые угольные брикеты для кальяна

Различные формы угольных таблеток для кальяна могут удовлетворить потребности большинства клиентов. Вот несколько причин, по которым так много людей выбирают уголь для кальяна:

- Хорошие рыночные перспективы: Уголь для кальяна — это местная культура и традиция Ближнего Востока. Многие жители региона используют сажистый уголь.

- Экологичность: некоторые люди предпочитают делать уголь для кальяна, потому что ищут более экологически чистый вариант табака. По сравнению с традиционными сигаретами, изготовление угля для кальяна уменьшает количество используемого табака и количество окурков, тем самым оказывая меньшее воздействие на окружающую среду.

- Экономические факторы: для коммерческих производителей производство угля для кальяна может снизить затраты и увеличить прибыль. Изготовление древесноугольных брикетов позволяет контролировать стоимость и доступность сырья, тем самым улучшая экономику производства.

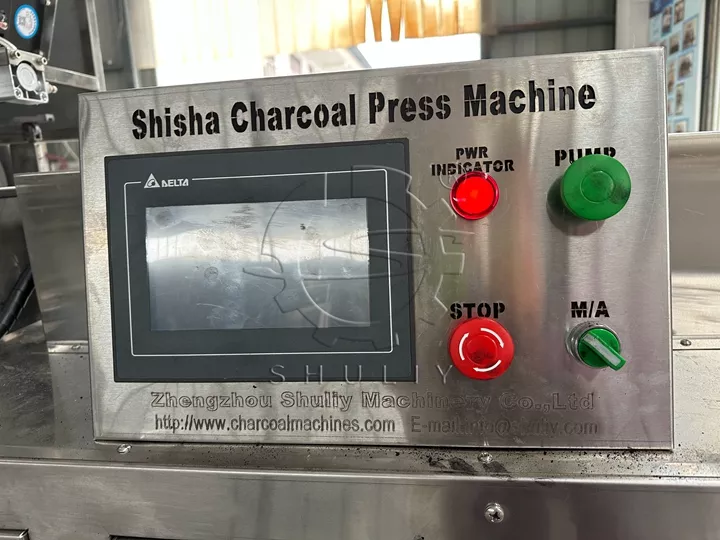

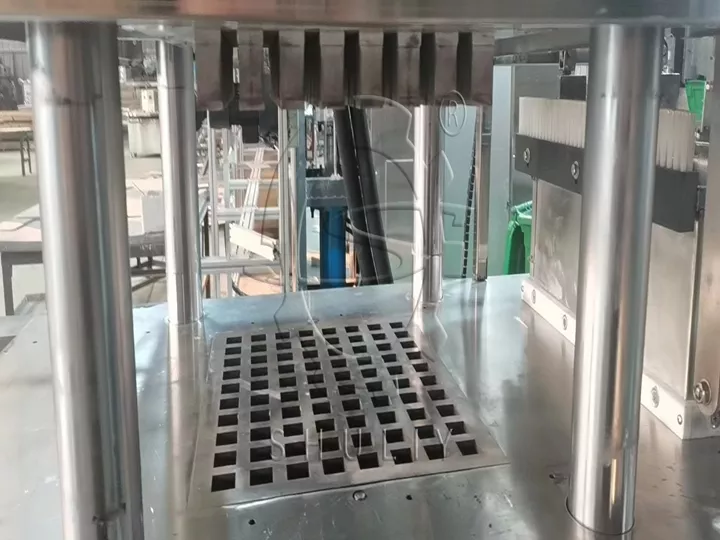

Конструкция гидравлического пресса для брикетирования древесного угля

Машина для производства древесного угля для кальяна в основном состоит из рамы машины, системы давления (которая является основной частью машины, обычно состоит из механизма давления, крышки пресса и формы для брикетов), системы нагрева, панели управления, разгрузочного отверстия и так далее.

Гидравлическая машина для производства древесного угля из нержавеющей стали обычно оснащена системой управления, которая может регулировать такие параметры, как давление, температура и время прессования, в соответствии с различными потребностями и требованиями к качеству древесного угля.

Процесс изготовления угольных брикетов для кальяна

Приготовьте угольный порошок

Прежде всего вам нужно подготовить угольный порошок или смесь угольного порошка в качестве сырья. Используйте печь для углеобжига сырья, чтобы карбонить ее сначала. Используйте измельчитель, чтобы измельчить обожженный уголь. После измельчения угольный порошок становится более изысканным.

Смешивание и перемешивание

Поместите подготовленный порошок древесного угля в загрузочный бункер устройства для изготовления древесного угля для кальяна. Тщательно перемешайте угольный порошок и связующее, чтобы обеспечить равномерное распределение. Мы рекомендуем клиентам использовать профессиональное связующее, которое поможет уменьшить зольность.

Прессование и формование

Запустите машину для производства угля для кальяна. Бункер угольной машины для кальяна открывается, чтобы засыпать угольный порошок в форму. Механизм давления создает давление для прессования порошка древесного угля в твердые угольные брикеты.

Выгрузка древесноугольных брикетов

После формирования брикетов из угля станок для изготовления кальянного угля из нержавеющей стали выталкивает брикеты угля. Это удобно для пользователей собирать брикеты угля. Высушите формованные брикеты угля в партии сушильной машине до нужной степени сухости и влажности. Используйте упаковочную машину для кальянного угля для упаковки готовой продукции на продажу.

Подробные фотографии различных форм.

Технические параметры пресса для кубического кальянного угля

Различные модели машин для производства угля для кальяна из нержавеющей стали могут иметь разные технические параметры. При выборе подходящей машины вам необходимо учитывать приведенные ниже технические параметры и другие возможные влияющие факторы в соответствии с вашими потребностями, масштабом производства и реальной ситуацией.

| Модель | Давление | Напряжение | Власть | Масса | Измерение |

| СЛ-СС | 80 тонн, 100 тонн | 380В | 13 кВт | 1000 кг | 2500мм*750мм*2300мм |

Почему стоит выбрать машину для производства угля для кальяна Shuliy?

- Качество и надежность: мы известный производитель. Продукция Шулия тщательно разрабатывается и производится. Выбор машины для производства древесного угля для кальяна Shuliy может обеспечить стабильность и долговечность оборудования.

- Настраиваемость: Мы предоставим клиентам индивидуальные варианты для удовлетворения потребностей и требований различных клиентов. Например, форма кальянного угля, мощность машины, операционная система машины и так далее.

- Разумная цена: Цена нашей машины для производства древесного угля для кальяна пропорциональна качеству машины. Цена на нее не будет завышена. Клиенты могут покупать с уверенностью.

- Качественное послепродажное обслуживание: Шулий будет иметь качественное послепродажное обслуживание, профессиональную техническую поддержку и сервисное обслуживание. Мы рассчитываем установить долгосрочные отношения с нашими клиентами и позаботиться о том, чтобы они получали своевременную поддержку и решали проблемы в процессе использования оборудования.

Согласно приведённому выше видео, наша компания производит и другие типы станков для изготовления кальянного угля, такие как вращающиеся станки для кальянного угля и гидравлические прессы для кальянного угля. По цене и детальной информации, пожалуйста, свяжитесь с нами!

Машина для производства брикетов из древесного угля для линии производства топлива

Машина для производства угольных брикетов предназначена для прессования угля или…

Ротационный аппарат для изготовления кальяна из угля для кальянных

Роторная машина для изготовления угля для кальяна — автоматическая, с двойным прессованием…

Пресс для угольных шариков для индустрии барбекю

Машины для прессования угольных шариков разработаны для сжатия рыхлого…

Клетчатая машина для формирования брикетов из угля

Машина для производства угля «соты» предназначена для использования хорошо переработанного угля…

Вертикальная коксующая печь для производства угля

Подъёмная карбонизационная печь используется для обжига древесины или…

Горизонтальная коксующая печь для обработки кускового угля

Горизонтальная карбонизационная печь — это вид оборудования для…

Непрерывная коксующая печь для производства угля из рисовой шелухи

Непрерывная печь для карбонизации угля — идеальное оборудование для сухой…

Пеллетный пресс для обработки биомассы

Опилки-брикетировочная машина предназначена для уплотнения отходов массы…

Упаковочная машина для угля для барбекю в линии производства брикетов

Упаковочная машина для древесного угля для барбекю — устройство, предназначенное для…

Многофункциональный упаковочный аппарат для угля для кальяна на продажу

В индустрии переработки угля упаковочная машина для кальянного угля…

Горячий продукт

Пресс для угольных шариков для индустрии барбекю

Шариковый пресс для древесного угля эффективен и удобен…

Машина для производства брикетов из древесного угля для линии производства топлива

Машина для брикетирования угля, также известная как брикетировочная…

Вертикальная коксующая печь для производства угля

Печь для производства древесного угля используется для обжига…

Мельница для кормовых гранул для животных

Гранулятор для корма используется для производства кормовых гранул для животных…

Автоматическая машина для прессования деревянных поддонов для продажи

Пресс для деревянных поддонов в основном обрабатывает сжатые деревянные…

Непрерывная коксующая печь для производства угля из рисовой шелухи

Непрерывная печь для карбонизации угля — идеальное оборудование…

Машина для очистки древесины от коры, оборудование для очистки бревен

Оснащённые лезвиями из высокопрочного сплава и усовершенствованным роторным…

Многофункциональный упаковочный аппарат для угля для кальяна на продажу

Упаковочная машина для кальянного угля — специальное оборудование…

Автоматический упаковочный аппарат для угля с термоусадочной пленкой

Усадочные машины для упаковки угольных брикетов идеально подходят…