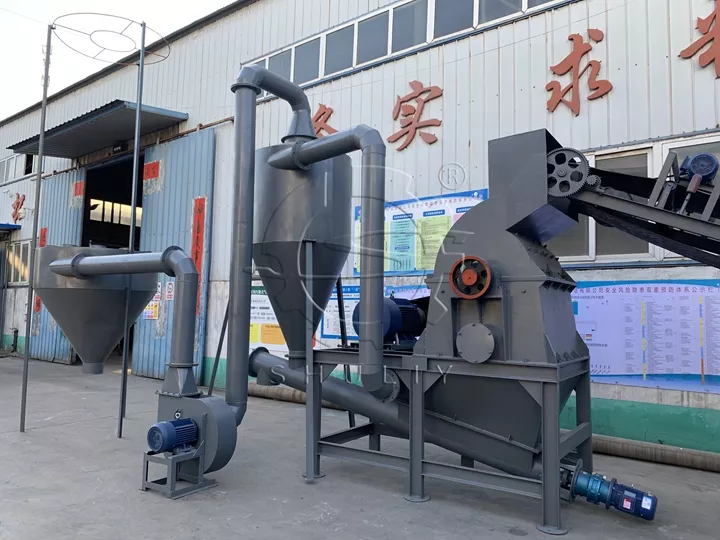

Grand broyeur à marteaux dans une usine de fabrication de sciure

Broyeur à marteaux | Machine de concassage de marteaux à bois

Grand broyeur à marteaux dans une usine de fabrication de sciure

Broyeur à marteaux | Machine de concassage de marteaux à bois

Aperçu des fonctionnalités

Le broyeur à marteaux à bois fonctionne en utilisant la rotation à grande vitesse des marteaux à l'intérieur de la machine pour décomposer les gros copeaux de bois en sciure de bois de 3 à 5 mm, essentielle à la production de granulés de bois et de sciure de bois.

Cette machine est capable de broyer des matériaux durs, mous et légèrement corrosifs, ce qui donne lieu à des particules de taille uniforme avec des niveaux d'humidité appropriés. Il trouve de nombreuses applications dans la transformation du bois, la production de granulés de biomasse, la transformation des aliments pour animaux, la fabrication de panneaux de bois et diverses autres industries.

Par rapport à d'autres types de broyeurs, le broyeur à marteaux à bois offre plusieurs avantages, notamment un taux de concassage élevé, une capacité de production élevée, une granulométrie constante et une faible consommation d'énergie. Selon la méthode de conduite, les concasseurs à marteaux peuvent être classés en électriques, diesel, à prise de force, etc. De plus, une base à roulettes peut être incluse pour une mobilité améliorée.

Large application de la machine de concassage à marteau

Le broyeur à marteaux n'est pas conçu pour traiter des matières premières collantes, grasses ou ayant une teneur en humidité excessive. De plus, les matières premières doivent être exemptes de métal ou d’autres corps étrangers durs.

En plus de broyer des matériaux typiques comme le bois, l'écorce, les copeaux de bois, les copeaux et les planches, le broyeur à marteaux est également capable de manipuler des tiges de récolte, du maïs, des coquilles de noix, des coquilles d'arachide, etc.

Par ailleurs, si le diamètre ou l’épaisseur du bois dépasse 4 cm, il est généralement recommandé d’utiliser d’abord une déchiqueteuse à bois pour réduire le bois épais en copeaux plus petits. (Article connexe : Machine à copeaux de bois pour l’usine de fabrication de sciure>>) Cette approche améliore non seulement le débit mais minimise également l’usure de la machine.

Produit fini du broyeur à marteaux

Le produit fini après traitement par le broyeur à marteaux en bois est généralement constitué de particules de bois broyées ou de matériaux fibreux, et sa forme et son utilisation spécifiques dépendent du type de matières premières et des exigences de transformation. Voici quelques produits finis possibles :

- Granulés de bois : ces granulés sont généralement utilisés pour la production d'énergie issue de la biomasse, comme les granulés de bois, pour le chauffage, la production d'électricité, etc.

- Granulés de biomasse : le broyeur à marteaux en bois peut également transformer la paille, le bambou, les tiges de maïs, etc. en granulés de biomasse. Ces pellets peuvent être utilisés comme aliment pour animaux, engrais organique, etc.

- Pâte de bois : une usine de copeaux de bois à marteaux peut également transformer le bois en pâte de bois pour la production de papier, de panneaux de fibres, de panneaux de particules et d'autres produits du bois.

Structure principale du broyeur à marteaux

Extérieurement, la partie principale de la machine comprend l'entrée, la chambre de concassage et l'orifice de décharge.

- Entrée: la matière première bois est mise dans la machine pour être concassée.

- Chambre de concassage: c'est la zone principale de concassage du bois, et il y a plusieurs lames de marteau rotatives ou marteaux à l'intérieur.

- Port de décharge: les copeaux de bois broyés sont évacués de la machine par l'orifice de décharge.

Plaque d’appui : dans le fonctionnement à haute intensité du processus de travail de la lame de marteau, pour protéger l’arrière de la machine, nous avons ajouté une plaque d’appui à l’intérieur, ce qui rend la machine moins sensible aux dommages, plus résistante à l’usure et avec une durée de vie plus longue.

Tamis : son rôle principal est de réguler la taille de sortie, et en ajustant l’écran avec différentes mailles, différentes tailles de produits finaux peuvent être obtenues.

Dispositif de cyclone et collecteur de poussière : après le broyage, le matériau peut être équipé d’un collecteur de poussière; le matériau est soufflé par le ventilateur dans le collecteur, associé au sac, et le rôle est de collecter la poussière pour éviter la pollution.

Avantages du broyeur à marteaux en bois

- La production d'un grand broyeur à marteaux peut atteindre trois à quatre fois celle d'un petit broyeur de bois.

- Il peut transformer des matières premières de tailles diverses ou inégales en particules de bois cohérentes.

- Différents tamis peuvent être choisis pour répondre aux différentes exigences de broyage des matières premières.

- Le broyeur à marteaux est soigneusement conçu dans un souci de sécurité et comprend des dispositifs de sécurité de protection.

- Les marteaux sont conçus pour une utilisation prolongée, ce qui les rend sujets à l'usure. Pour améliorer la durabilité contre les chocs, les coins de la tête du marteau sont renforcés avec un alliage résistant à l'usure.

Comment fonctionne le broyeur à bois à marteau ?

Lorsque le concasseur à marteaux fonctionne, le moteur fait tourner l'arbre rotatif, ce qui fait tourner rapidement les marteaux qui y sont attachés. Les matériaux en bois sont introduits dans la chambre de concassage par l'entrée et sont rapidement brisés par la force des marteaux rotatifs à grande vitesse.

Le matériau broyé obtenu est ensuite tamisé à travers un grillage à l'intérieur de la machine. La taille des ouvertures du tamis peut être ajustée pour contrôler la taille des particules du produit final. Les particules plus petites peuvent passer à travers les mailles, tandis que les plus grosses restent à l'intérieur de la machine pour être broyées davantage.

Données techniques du broyeur de bois à marteau

| Modèle | SL-60 | SL-70 | SL-80 | SL-90 | SL-1000 | SL-1300 |

| Puissance (kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Marteaux (pièces) | 30 | 40 | 50 | 50 | 105 | 105 |

| Ventilateur (kW) | 7.5 | 7.5 | 11 | 22 | ||

| Dépoussiéreur (pièces) | 5 | 5 | 5 | 5 | 14 | 14 |

| Diamètre du cyclone (M) | 1 | 1 | 1 | 1 | 1 | 1 |

| Capacité (T/h) | 0.8-1 | 1-1.5 | 1.5-2 | 2-3 | 3-4 | 4-5 |

Notre conception simple, notre taille compacte, notre fonctionnement convivial et notre entretien minimal font de cette machine le premier choix pour les maisons, les fermes ou les petites usines de granulés. Nous pouvons adapter la taille à vos besoins spécifiques. N'hésitez pas à demander les prix les plus récents sur le broyeur à marteaux à bois !

Machine à briquettes de sciure pour la ligne de traitement du charbon de biomasse

La machine à briquettes de sciure de bois est conçue pour comprimer les déchets…

Machine de séchage à tambour rotatif pour l'usine de séchage de poudre de sciure

La machine de séchage à tambour rotatif est couramment utilisée pour évaporer…

Machine à broyer le bois pour fabriquer de la sciure

La machine de broyeur de bois est équipée de couteaux rotatifs à grande vitesse et d'un…

Machine à scier automatique pour l'usine de recyclage du bois

La scierie utilise soit une scie circulaire, soit une scie à bande…

Machine à décapeur de bois pour écorçage de troncs

L'écorceuse de bois, équipée de lames en alliage à haute résistance et de technologies avancées…

Machine à copeaux de bois pour litière animale

La machine à raser le bois est conçue pour transformer le bois de…

Machine à déchiqueter le bois pour l'usine de fabrication de sciure

La déchiqueteuse à bois est conçue pour briser le bois,…

Machine de broyage à grande capacité pour le broyage de bois

Le concasseur complet est conçu pour briser les gros morceaux…

Machine à pellets pour alimentation animale

La machine de broyage de granulés alimentaires est une sorte d'équipement…

Machine automatique de presse à palettes en bois à vendre

La presse à palettes en bois est notre produit phare, principalement…

Produit chaud

Machine à déchiqueter le bois pour l'usine de fabrication de sciure

La déchiqueteuse à bois est conçue pour casser…

Machine rotative à charbon de narguilé pour les briquettes de narguilé

La machine rotative de fabrication de charbon de chicha est une double pression…

Machine à broyer le charbon pour l'usine de moulage de briquettes

La machine à broyer le charbon de bois a pour fonctions de concassage,…

Machine à copeaux de bois pour litière animale

La machine à raser le bois est conçue pour traiter…

Machine hydraulique à briquettes de charbon de shisha pour la formation de charbon

La machine hydraulique à briquettes de charbon de chicha est également un…

Machine multifonctionnelle d'emballage de charbon de narguilé pour la vente

La machine d'emballage de charbon de narguilé est un équipement spécial…

Machine de séchage à tambour rotatif pour l'usine de séchage de poudre de sciure

La sécheuse à tambour rotatif est une machine industrielle courante…

Machine d'emballage de charbon de barbecue dans la ligne de production de briquettes

Une machine d'emballage de barbecue au charbon de bois est une machine spécialisée…

Machine à décapeur de bois pour écorçage de troncs

Équipé de lames en alliage à haute résistance et d'un système rotatif avancé…